Table 1 — physical data, Rigging and unit placement – Carrier 50BA User Manual

Page 2

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

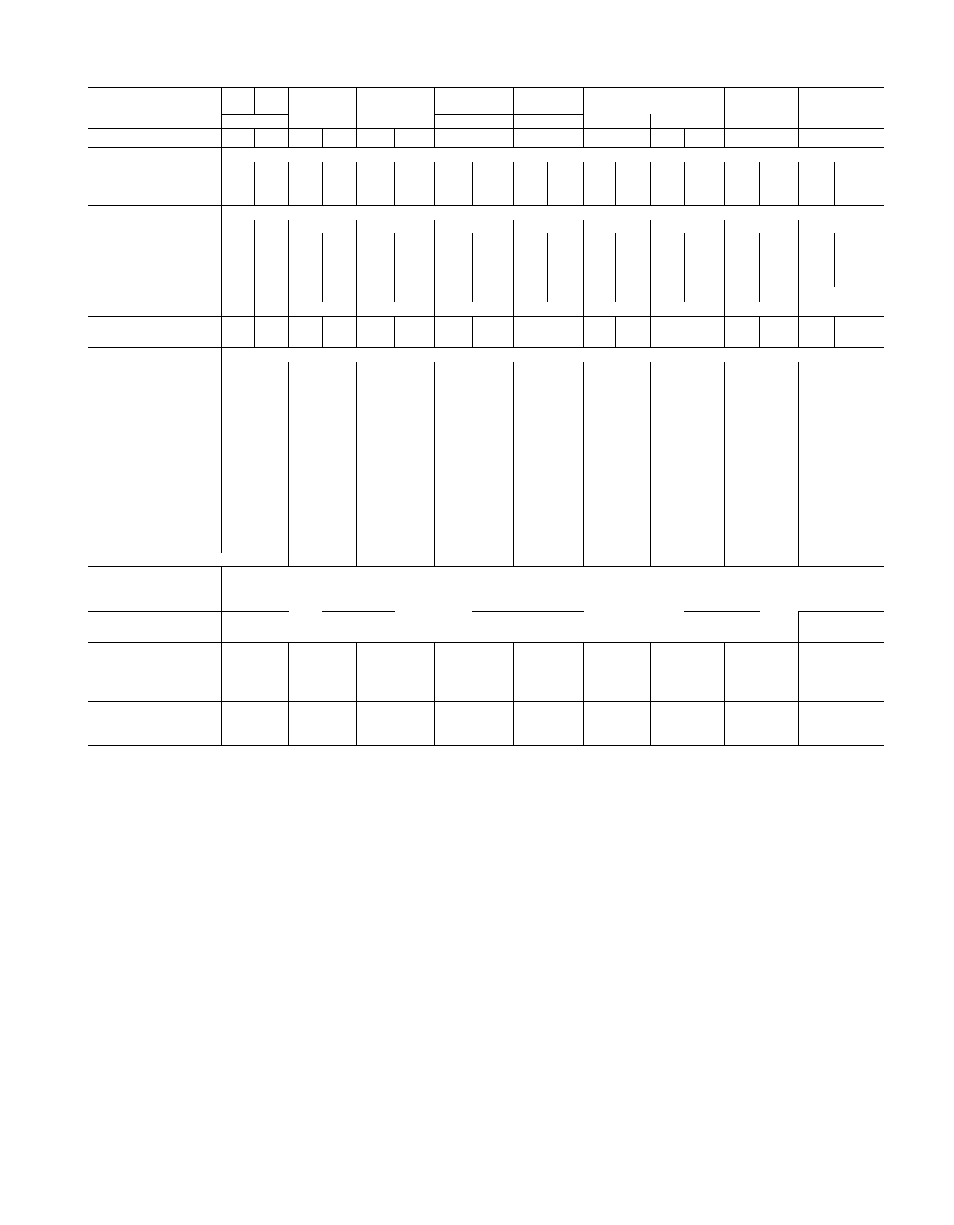

Table 1 — Physical Data

UNIT 50

BA

BB

BB

BA

BB

BA

BB

■

BA

BB

BA

BB

BA

BB

BA.

BB

BA

BB

008

012

016

024

028

034

044

0S4

064

OPER WEIGHT (lb)

770*

710*

950*

890*

1414*

1221*

1894-

1464*

2491

2327

2598

2430

3800

3100

4100

3300

4404

3550

OPER CHARGE (lb)

R efrigerant 22t

Sys 1

10

7

10

8

24

15

17

7

24

15

24

15

24

15

29

15

52

25

Sys 2

-

-

-

-

-

17

7

17

12

24

15

24

15

29

15

52

25

Sys 3

-

-

-

-

-

-

-

-

-

-

-

17

11

29

15

-

-

COMPRESSOR

1750 rprn at 60-Hz {Note 1)

06-

R

DA

DB

DD

DA

DA

DA

DA

DA

EAt

Sys 1

249

818

724

824

337

537

724

824

337

537

337

537

337

537

337

537

175

275

Sys 2

_

-

-

-

-

-

724

824

724

824

337

537

337

537

337

537

175

275

Sys 3

-

-

-

-

-

-

-

-

-

-

-

-

724

824

337

537

-

-

Unloading Cylinder

0

0

2

2

2

2

0

0

0

0

0

0

0

0

0

0

4

4

Capacity Steps

1

1

2

2

2

2

2

2

2

2

2

2

3

3

3

3

2 or 4

Oil Capacity (Pfs)

s

7

10

10

10 ea

10 ea

10 ea

10 eo

10 eo

17 ea

CONDENSER, Type

Tf

_

TT

-

SC

-

SC

-

SC

-

SC

-

SC

SC

_

ST

-

Number

1

-

1

-

1

-

2

-

2

”

2

-

3

-

3

--

2

-

EVAPORATOR FAN

1725 Rpm; Belt-Driven ^ _entriugn 1

Nominal Cfm

3000

4000

6000

8000

10,000

12,000

16,000

20,000

24,000

2250-

3000-

4500-

6000-

7,500-

9,000-

12,000-

15,000-

20,000-

Range Cim

3750

5000

7500

10000

12,500

15,000

20,000

25,000

25,000

Nominal Motor Hp

1 0

2 0

2 0

3 0

5 0

5 0

7 5

10 0

15 0

Frame (NEMA)

56

145T

145T

182T

184T

184T

213T

256 U

284 U

Motor PDR (Note 2)

2 4 -3 4

2 4 -3 4

3 7 -4 7

4 0 -5 0

4 3 -5 3

4 3 -5 3

5 6,6 0,6 4

5 8,6 2,6 8

7 0,7 4,8 0

Fan PPD

8 5

7 0

1

4

10 0

12 4

1

0

15 4

15 4

15 4

Belt No. ... Length

1

35

1

35

1

49

2

45

2

88

2

88

2

63

2

100

2

98 8

FSR (Rpm) (Note 2)

495 --700

600 -850

568 -720

700 -875

605 -750

685 -845

627,672,717

650,695,762

785,828,895

Speed Change per

Vi

turn of Pulley

18

22

14 5

17 5

14 5

16 0

-

-

-

Flange (Rpm)

Moveable Pulley —

Max full turns from

5K.

5K>

6

5

6

6

-

-

-

Closed Position

PRESSURESTAT

Setting s (psig)

, Cutout

BA-280

BB -375

High _ , .

® Cut-in

BA -180

BB-275

, Cutout

27

29

Low _ .

Cut-in

60

63

EVAPORATOR COILS

Rows

3

3

3

4

4

4

4

4

4

Fins/ln.

13

13

13

1

1

11

11

11

13

Face (sq ft)

7 31

8 54

16 90

18 04

22 6

26 9

36 5

46 3

46 3

FILTERS, Low Vel**

3 16x25x2

6 25x20x2

6 25x20x2

10 20x25x2

10 20x25x2

No. ..Size (in.)

4 16x20x1

4 16x20x1

3 20x25x2

3 .20x25x2

2 16x20x2

2 16x20x2

5 16x25x2

5 16x25x2

t

FSR -

PDR -

PPD -

SC

ST

TT

Fan Speed Range

Pitch Diameter Range

Pulley Pitch Diameter

Shell and Coil

Shell and Tube

Tube in Tube

Add 140 lb for plenum

Does not include charge for matching air-cooled condenser or

connecting

piping

used

with

50BB

units

All

50BB

units

are

shipped with holding charge

4O6EE on System 2

**Filters shown are supplied with unit Field-supplied 2-in filters

will fit 008 and 01 2 units

NOTES:

1 Compressor rprn on 50BA008 is 3450

2

Fan motor pulleys on 50BA.BB044, 054 and 064 are fixed

pitch

3

Maximum fan speed for all units is 11 00 rpm

Rigging and Unit Placement

— Inspect unit for

shipping damage. File any claim with trans

portation agency. Provide space around unit for

service, filter access, and clearance for plenum, if

used. Move and store unit in upright position. Use

slings with spacer under base skid to prevent panel

damage when using hoist. Raise base skid on blocks

and remove bolts. On 028 thru 064 units, unbolt

fan section from skid. Units, as shipped, are

adequately dampened against vibration. However,

if additional dampening is desired, place sponge

rubber, rubber mat or fiberglass roof insulation

between floor and base of unit or install vibration

isolators.

Units 50BA,BB008 thru 024

are shipped for

vertical discharge. If horizontal discharge is desired

on 008 and 012 units, a field-fabricated elbow

must be installed. On 016 and 024 units for top

mounted horizontal discharge, accessory filler

panels must be field installed (see Fig. 2).

I