Fig. 22 — refrigeration circuits (016 — 064), Fig. 23 — field power wiring connections, Thermostats – Carrier 50BA User Manual

Page 10: L3---- —[i

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

REFRIGERANT IN

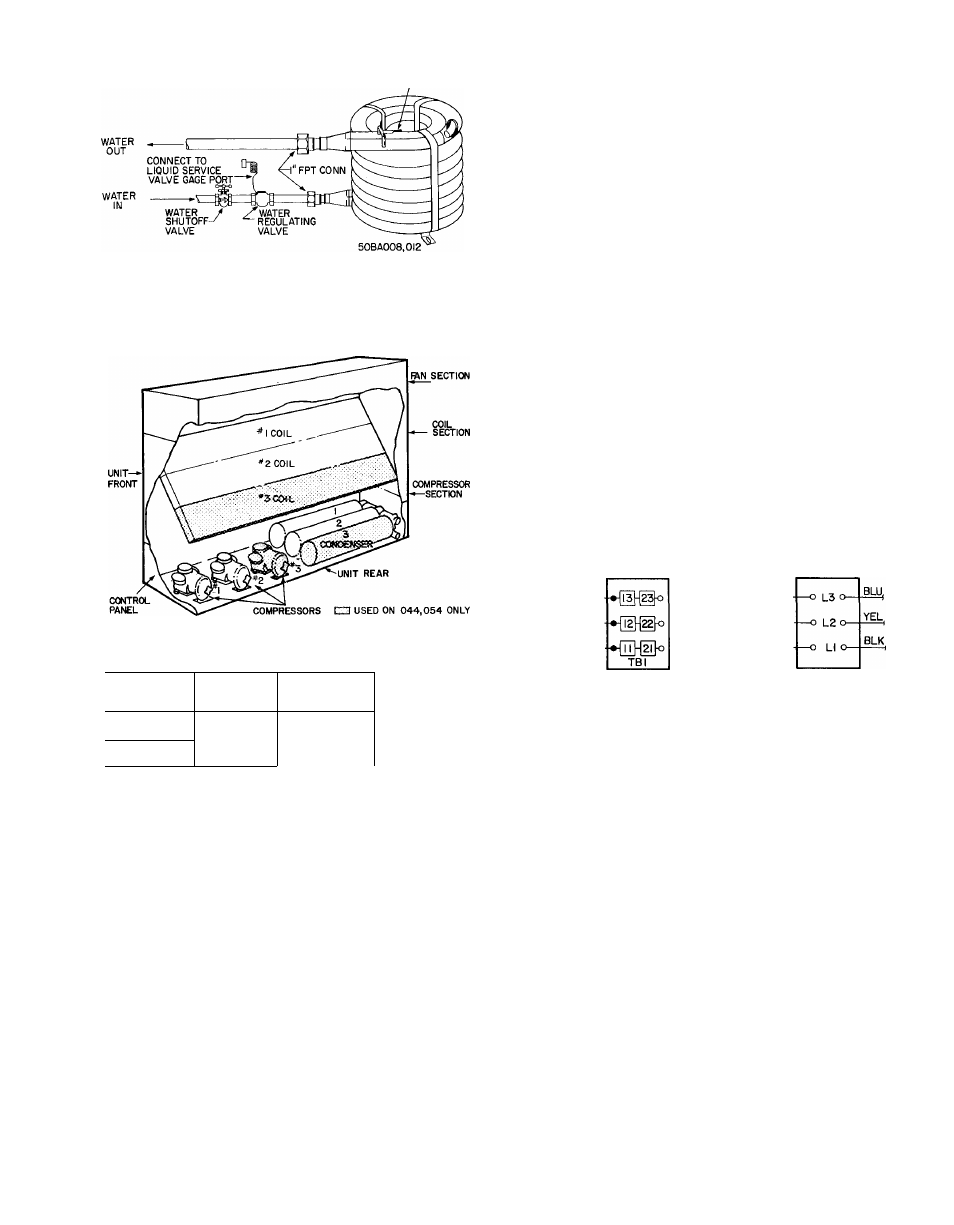

Fig. 21 — Condenser Water Piping, 50BA008,012

Refrigerant Systems

50BA,BB*

COIL NO.

COMPR NO.

016

1

1

024,028,

034,064

044,054

1, 2, 3

1, 2, 3

COND NO.*

1

1

,

2

1, 2, 3

*50BB units are condenserless

Fig. 22 — Refrigeration Circuits (016 — 064)

percent. Contact local power company for cor

rection of improper voltage or phase imbalance.

Failure of unit due to imbalance constitutes abuse

and may damage electrical components. Such

operation will invalidate any applicable warranty.

Field power may be supplied to the unit by a

feeder circuit. The branch circuit protection is

provided in the unit by manual reset circuit

breakers. The feeder circuit must be sized in

accordance with National Electrical Codes or local

codes, whichever takes precedence. The power

supply to auxiliary equipment such as air-cooled

condenser fan motors and cooling tower must be

run separately. See the electrical data table for base

unit power requirements.

The power wiring is brought into the unit thru

the conduit opening in the panel on the back of

the unit near the control panel (see Fig. 23). (On

50BA,BB064 units, power wires may be routed

thru front or back). The field power connections

are made at the terminal block inside the control

panel on the 016 thru 054 units. On the 064 unit,

the terminal block is on the back of the control

panel. Remove the metal shield for access to the

terminal block. Be sure to reinstall shield after

connecting power wiring.

FIELD

POWER

SUPPLY

FIELD

POWER

SUPPLY

50BA,BB008,0I2

50BA,BB0l6-054

TB3

-------- FIELD WIRING

-------- FACTORY WIRING

/ L3---- —[I]-

FIELD I

POWER j L2-

SUPPLY /

(

li

-----------Q}-

50BA, BB064

Fig. 23 — Field Power Wiring Connections

i

i

Service Valves (50BB)

— Teflon seat washers are

used to provide positive seal with minimum stem

torque (10 ft—lb max). Do not overtighten valve

stem. Use wet rag on valve when soldering. Midseat

valve if refrigerant has been lost. Always replace

stem cap.

Power Supply Wiring

— Unit is factory-wired for

voltage shown on nameplate. All field wiring must

comply with National Electrical Codes and local

codes.

Voltage at the unit with the compressors

operating must be within the voltage range indi

cated on unit nameplate. (Also see Table 6). On

3-phase units, voltage between phases must be

balanced within 2 percent and current within 10

Thermostats

The 50BA,BB008 and 012 model units have

thermostats factory installed with the sensing bulb

in the return air. A field-supplied thermostat must

be used on the 50BA,BB016 thru the 064 size

units (see Fig. 24 for control wiring).

Two-step thermostats are recommended fir

capacity control. Three-step thermostats may be

used on the 50BA,BB044,054 and 064 size units.

Minimum recommended rating is 125 va at 230

volts. See Table 9 for recommended connecting

sequence for the 2-step thermostats. See wiring

booklet if other type controls are used.

I

10