Carrier 50BA User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

PILLOW BLOCK

FAN SHAFT

BEARING s

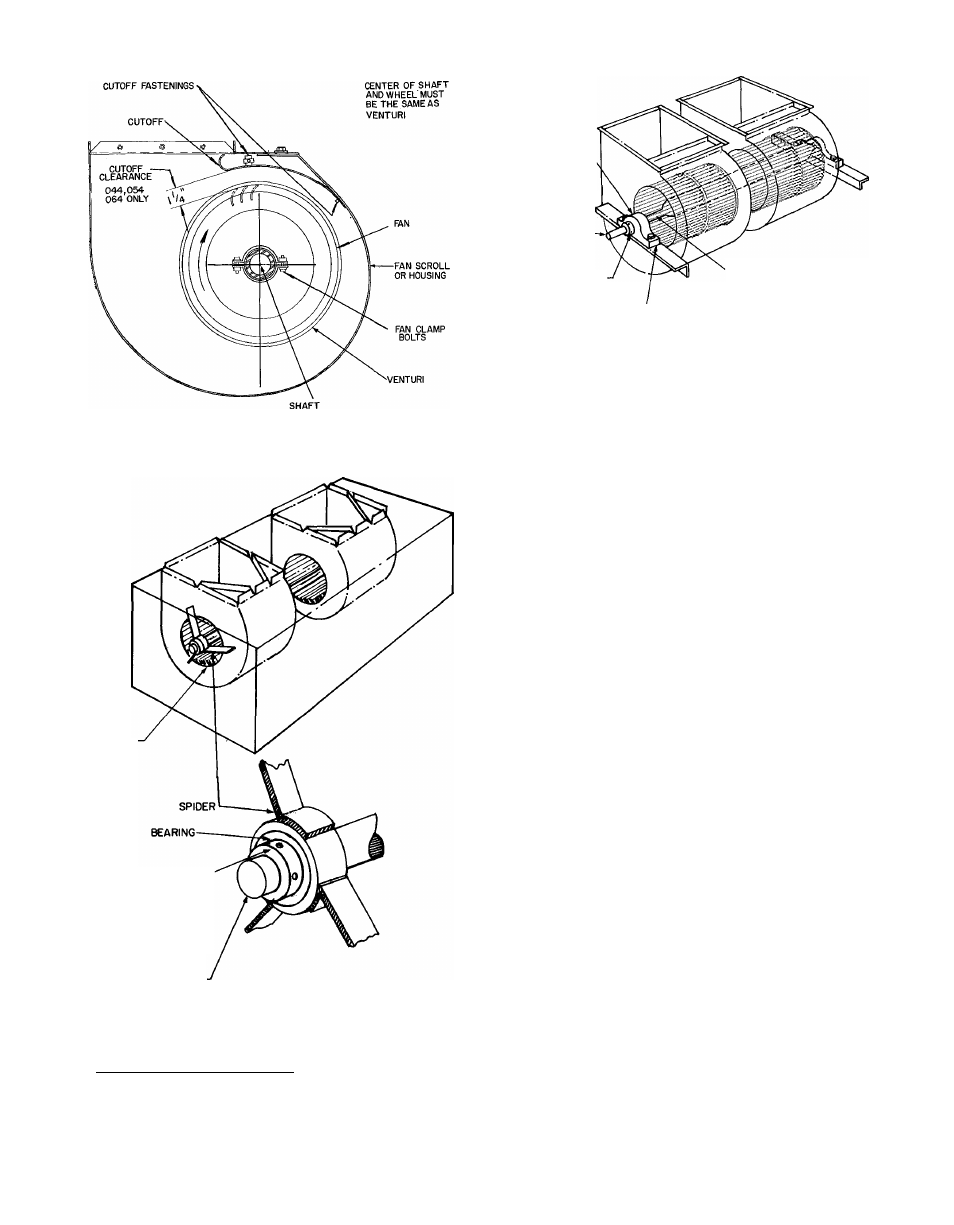

Fig. 11 — Concentric Alignment

VENTURI

LOCKING COLLAR

SHAFT

Fig. 12 - Fan Shaft Bearings

-008,012,016,024

Units 50BA,BB028 thru 064 — Bearings are bolted

to an angle support fastened to fan scroll, Fig. 13.

If shaft and wheels are concentrically misaligned:

1. Loosen bearing support bolts and shim or move

if necessary.

2. Retighten bearing support bolts.

SHAFT EXTENSION

LONGER ON

ONE END TO

ACCOMMODATE

DRIVE PULLY

BEARING LOCKING

COLLAR 2 SET SCREWS

HOLLOW SHAFT

3 FANS ON 054 8064

'

shim

IF NECESSARY

Fig. 13 — Horizontal Shaft Alignment

HORIZONTAL

SHAFT

ALIGNMENT

(ALL

UNITS) — If shaft has moved and all wheels are off

horizontal center, recenter the shaft. To correct.

1. Loosen setscrews holding bearing locking collar.

One on each end of shaft (Fig. 12 or 13).

2. Slide shaft and wheel assembly horizontally

until wheels are horizontally centered (Fig. 9).

3. Slide bearing locking collars against bearing

race; turn in direction of shaft rotation until

tight.

4. Retighten locking collar setscrews.

CUTOFF CLEARANCE (044, 054 and 064 Units

Only ) — After centering and aligning fan wheel,

loosen cutoff sheet, adjust for 1-1/4 in. clearance

(all sizes) and then tighten securely. See Fig. 11.

Evaporator Fan Adjustment

— Refer to Service

Section.

Field-Fabricated Ductwork

— Secure all ducts to

building structure. Use flexible duct connectors

between unit and ducts as required. Insulate and

weatherproof any external ductwork, joints and

openings with flashing and mastic in accordance

with applicable codes.

Ducts passing thru an unconditioned space

must be insulated and covered with a vapor barrier.

Return Air Filters

— Check that filters shipped in

unit are the correct size. Refer to Table 1. Do not

operate unit without return air filters in place.

Spring-Mounted

Compressors

(50BB008

and

50BA,BB012 thru 064)

— Held rigid in shipment

by 4 bolts which extend thru a washer, grommet,

and compressor foot into a weld nut (except on

064 unit). Loosen bolt until compressor floats free

on springs. Retighten bolts so there is a slight

pressure on the neoprene grommet. This will steady

compressor and prevent start and stop rocking.

The 50BA,BB064 units are shipped with 4

special flanged washers and neoprene grommets in

a cloth bag tied to the compressor.

#

i