Carrier 39B User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Table 4 — Setscrew Torques

SETSCREW SIZE

TORQUE

10

22 5- 30.5 in.-lb

1/4

52.7- 71 3 in.-lb

5/16

103.7-140.3 in.-lb

3/8

168.3-227.7 in.-lb

7/16

22.1- 29 9 ft-lb

1/2

32 3- 43 7 ft-lb

5/8

78.2-105.8 ft-lb

3/4

107.9-146.1 ft-lb

INSTALLATION

General

DO NOT

1. Remove protective caps from coil piping con

nections until ready to connect piping.

2. Bend or mutilate coil fins.

3. Remove protective cover or grease from fan

shaft until ready to install sheave.

4. Lift by fan shaft extension or coil connections.

5. Remove fan drive from boxes until ready to

install, to prevent loss of parts and installation

information labeled on boxes.

6. Lift face and bypass damper assembly without

providing support under center of assembly.

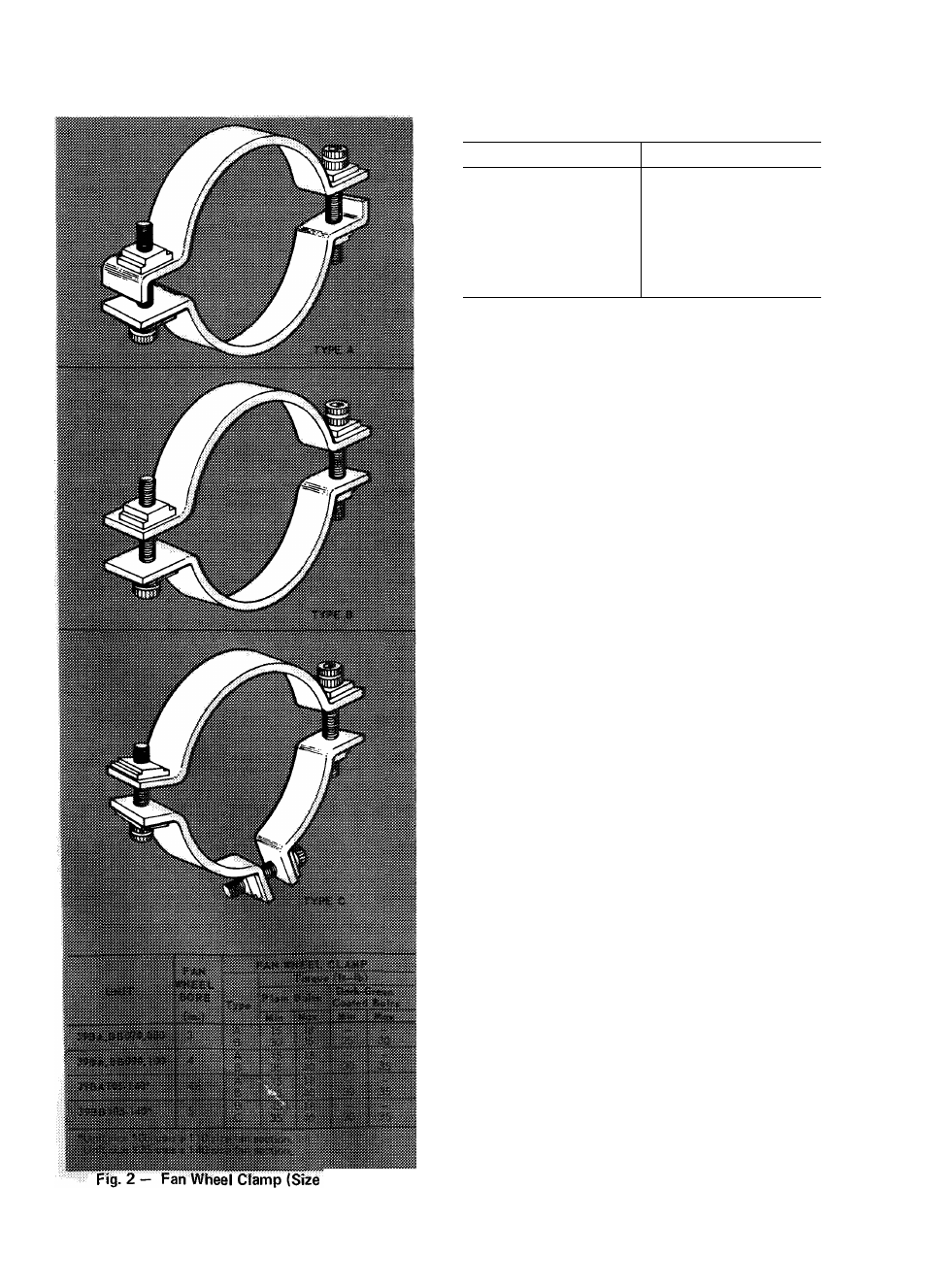

076-140)

DO

1. Use spacer bars per Fig. 1 when rigging to avoid

bending unit flanges.

2. Make piping and duct connections in accord

ance with standard practices. Refer to Carrier

System Design Manual for details.

3. Leave sufficient clearances for:

a. Condensate trap.

b. Removal of fan shaft and coils.

c.

Service of filters, fan motor, bearings,

damper linkage, and damper motors (at least

30 inches).

d. Piping to permit removal of fan guard.

Base Unit Assembly (Fan and Coil Sections)

NOTES:

1. Base unit and accessories on 39BA sizes 040

thru 060 (arrangements A, B, and D) are

shipped completely assembled, except for

accessory

mixing

box

which

is

shipped

separately.

2. More holes may exist than indicated by these

instructions. Use only those which line up.

3.

Fastener package is shipped with each fan

section. Sealing compound is shipped inside

belt guard.

4. Remove any accessories attached to base unit

that are not in their final location per Tables 1,

2, and 3.

5. Unit suspension is simplified by completely

assembling units prior to rigging.

6. Unit sizes 130 thru 140 must be assembled on a

platform for suspended applications.