Carrier 39B User Manual

Page 21

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

'Г

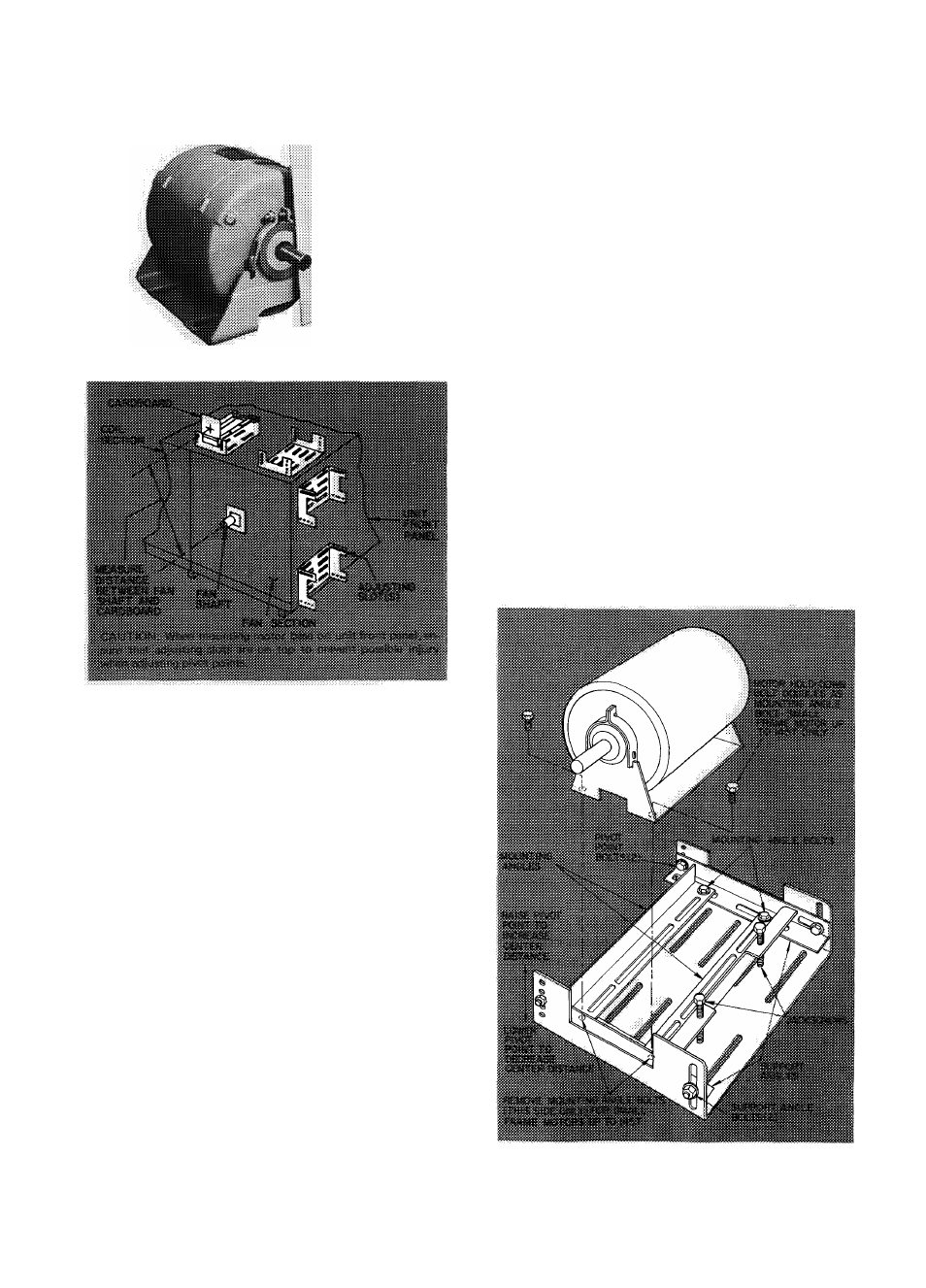

Fig. 23 — Cardboard Pattern

Fig. 24 — Location of Adjusting Slots

(Unit Sizes 070 thru 140)

2. Place motor on motor base with maximum

shaft overhang and install hardware from

accessory drive package; tighten securely. Posi

tion small frame motors up to 145 T per

Fig. 25. Note that hold-down bolts for small

frame motors will be smaller in diameter than

mounting angle bolts supplied in motor base,

Fig. 25.

3. Locate mounting angles so motor shaft will

hne up with center of cutout in motor base.

Make certain mounting angles are perpendic

ular to support angles and secure mounting

angle and motor hold-down bolts shown in

Fig. 25.

4. Remove protective cover and clean grease from

fan shaft with solvent.

5. Apply a light coat of grease or white lead to

fan shaft.

6. Install fan and motor sheaves with correct

angular and parallel alignment per Fig. 22.

7.

Correct alignment by repositioning motor

base.

8. Secure motor base hold-down bolts.

9. Loosen two support angle bolts per Fig. 24

and adjust belt tension by turning jackscrews.

Follow step 7 of Motor and Drive (imit

sizes 040 thru 060). A pry bar may be used to

support weight of motor.

10. Secure two support angle bolts and loosen

jackscrews.

11. Adjust motor base after mounting motor as

follows:

NOTE: If center-to-center distance was not

properly set before mounting motor, adjust

base height as follows for proper belt tension:

a.

Turn jackscrews until they contact motor

base cradle.

b.

Block up motor under mounting angle

nearest pivot points to support weight of

motor. Place lever (pry bar or 2 x 4 for

example) under same area.

c.

Loosen two support angle bolts, and

adjust jackscrews until two support angle

bolts are approximately centered in ad

justing slots.

d.

Remove two pivot point bolts, raise or

lower pivot point to obtain correct

center-to-center distance. Replace pivot

point bolts.

e.

Refer to preceding step 9 for final adjust

ment of belt tension.

f.

Secure two support angle bolts and two

pivot point bolts, and loosen jackscrews.

Fig. 25 — Small Frame Motor Mounting

(Such as 143T and 145T)

21