Carrier 39B User Manual

Page 16

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

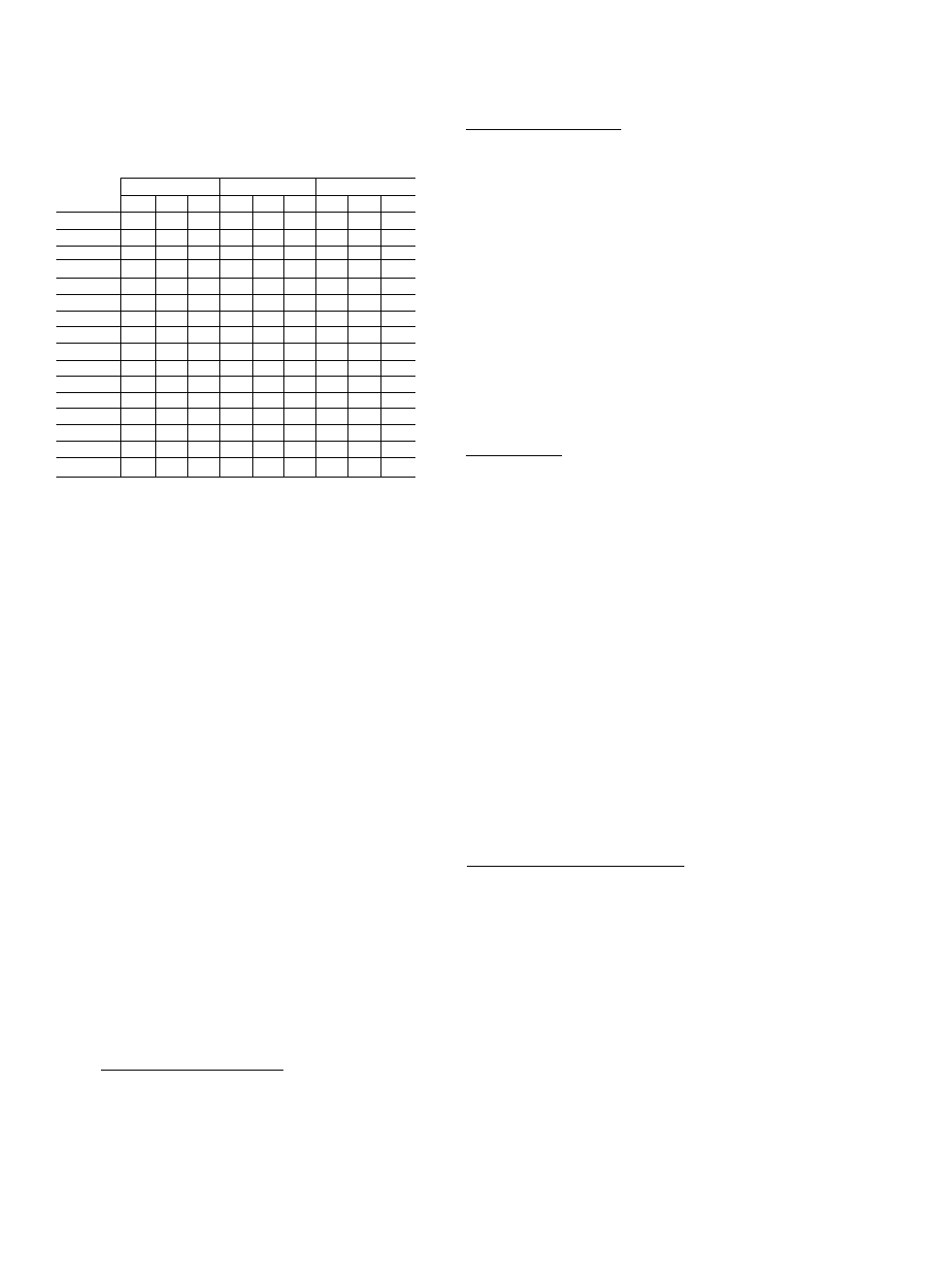

Table 6 — Refrigerant Distributor Nozzle Orifice

Capacities (Tons of Refrigeration)

NOZZLE

EVAPORATOR TEMPERATURE

ORIFICE

R-12

R-22

R-500

NUMBER

40 F 30 F 20 F

40 F 30 F 20 F

40 F 30 F 20 F

2

2.0

1.7

1.4

3.2

2.7

2.3

2.3

1.9

1.6

2-1/2

2 5

2.1

1.8

4.0

3.3

2 8

2 9

2.4

2.0

3

3.0

2.5

2.1

4.8

4.0

3.4

3.4

2.8

2.4

4

4.0

3.3

2 8

6.5

5.5

4 6

4 6

3.8

3 2

5

5.0

4.2

3.5

8.0

6 5

5.5

5.5

4.6

3 9

6

6.0

5.0

4.2

9.5

8.0

6.5

7.0

6.0

5 0

8

8.0

6.5

5.5

12 5

10.5

8.5

8.5

7.0

6.0

10

10.0

8.0

7.0

15.0

12.5

10.5

11.0

9.0

7.5

12

12.0

10.0

8.0

18.5

15.0

12 5

13.5

11.0

9.5

15

15,0

12,5

10.0

23.0

19 0

15.5

17,0

14 0

11.5

17

17.0

14.0

11 5

26.0

21.0

18.0

19 0

15.5

13 0

20

20 0

16.5

13.5

31.0

25.0

21.0

23.0

19 0

15.5

25

25 0

21 0

17.0

39.0

32.0

27 0

28 0

23 0

19.0

30

30.0

25 0

20.0

45 0

37.0

31.0

33.0

27.0

23.0

35

i

35.0

29 0

24.0

54 0

44 0

37 0

39.0

32 0

27.0

40

40 0

33 0

27.0

60 0

49.0

41 0

44.0

36 0

30.0

NOTES:

1 Orifice sizes 2-1/2, 3, 4, 5, 6 and 8 are not available for "A"

nozzles

2. Nozzle designation is stamped on nozzle; "G" indicates 7/8 in.

ODM distributor, "E" indicates 1-1/8 in. ODM distributor, "C"

indicates 1-3/8 in, ODM distributor, "A" indicates 1-5/8 in.

ODM distributor. Therefore, only the nozzles having the same

letter are physically interchangeable.

c. Standard coils above size 080 are face split

with the load for each coil divided evenly

between the two or three distributors. Unit

sizes 130, 135 and 140 contain two coils,

each of which are face split. The percentage

of total unit load handled by each distrib

utor is as follows:

(1) Unit sizes 040 thru 080; 100%

(2) Unit sizes 090 thru 120: 50% except

8-row coil on 120

(3) Unit size 120 with 8-row coil: 33-1/3%

(4) Unit size 130; 25%

(5) Unit size 135; 23% for each distributor

of the smaller coil and 27% for each

distributor of the larger coil.

(6) Unit size 140 with 4- and 6-row coil;

20% each distributor of smaller coil; 30%

each distributor of larger coil.

(7) Unit size 140 with 8-row coil: 20% each

distributor of both coils.

2. Factory-installed nozzle should be replaced if

the following relationship is not met;

design load (per distributor) = g 90 to 1 20

nozzle orifice capacity (Table 6)

3.

If two nozzles satisfy above relationship,

choose the smaller.

4. Mark final nozzle size, where indicated, on unit

label for future reference. This will show nozzle

size has been checked.

Partial Load Operation — System controls must be

designed with consideration of following:

1. No coil or coil split served by a single refrig

erant distributor and expansion valve can be

expected to operate satisfactorily at less than

50% of design load.

2. As load reduces, a portion of coil surface must

be deactivated so that remaining active coil or

coil splits operate between 50 and 100% of

design load.

3. Face-split coils may be used when air quantity

is constant. In variable volume systems, row-

split coils must be used.

4. If operation must be below 50% of design load,

hot gas bypass must be used. Refer to Carrier

System Design Manual for details.

Suction Piping

1. Connect suction piping per Fig. 14,15 and 16.

2.

Suction line from evaporator to end of

15 diameter long riser (located between reducer

fittings) must be sized for high velocity. Refer

to Carrier System Design Manual, Part 3 for

suction pipe sizing charts. This piping length

will normally result in an equivalent length of

20 ft and should be sized for a pressure loss

corresponding to 0.5 F. Remaining suction Mne

should be sized for a pressure drop correspond

ing to 1.5 F for a total suction line pressure

drop corresponding to 2 F.

3. Suction risers must be sized to provide ade

quate oil return at minimum load. When a

suction riser is designed to permit oil return at

minimum load, the pressure drop at full load

may be too great. If this situation occurs, a

double suction riser should be used. Refer to

Carrier System Design Manual for details of

sizing.

Expansion Valve (field-supplied)

1. Expansion valve must satisfy following;

a. Design load per distributor.

b. Available pressure drop.

c. Valve inlet temperature (condensing tem

perature minus subcooUng).

d. Design evaporator temperature.

e. Valve must have non-condensing charge

power element.

f. If selection falls between two valves, choose

smaller.

2. Install expansion valve(s). Refer to Fig. 14, 15

and 16 for proper location of sensing bulb and

equalizer connection.

3.

Install condensate pan(s) under expansion

valve(s) per Fig. 17.

1 A