Belt guard, Start-up – Carrier 39B User Manual

Page 22

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Belt Guard

UNIT SIZES 040 THRU 120

1. Position belt guard and drill three engagement

holes (sizes 040 thru 060) with a no. 5 drill or

four engagement holes (sizes 070 thru 120)

with a no. 3 drill in side of fan section using

mounting bracket clearance holes as templates.

2. Secure guard to fan section with three

1/4-20

X

1/2-in. self-tapping screws.

UNIT SIZES 130 THRU 140

1. Position belt guard and drill eight engagement

holes with a no. 3 drill in side of fan sectit i,

using mounting bracket clearance holes a:

templates.

2. Secure guard to fan section with eight

1/4-20 X 1/2-in. self-tapping screws.

3.

Position two unattached mounting brackets

over unit front or top structural member and

secure to guard with four 1/4-20 x 1/2-in.

self-tapping screws and guard engagement holes.

4. Drill four engagement holes in unit structural

members with a no. 2 drill, using mounting

bracket clearance holes as templates.

5. Secure two mounting brackets to unit struc

tural members with four 1/4-20 x 1/2-in. self

tapping screws.

START-UP

Check List

1. Make certain all construction debris is removed

from unit interior.

2. Check lubrication of fan and motor bearings.

a. Note that bearings are shipped completely

full of grease for corrosion protection and

may run warm temporarily on start-up until

the excess grease has discharged. As a

precaution, cycle unit on and off at one-

minute intervals for five minutes.

b. Sleeve bearing motors are normally shipped

with oil reservoir drained. Fill reservoir

before starting motor.

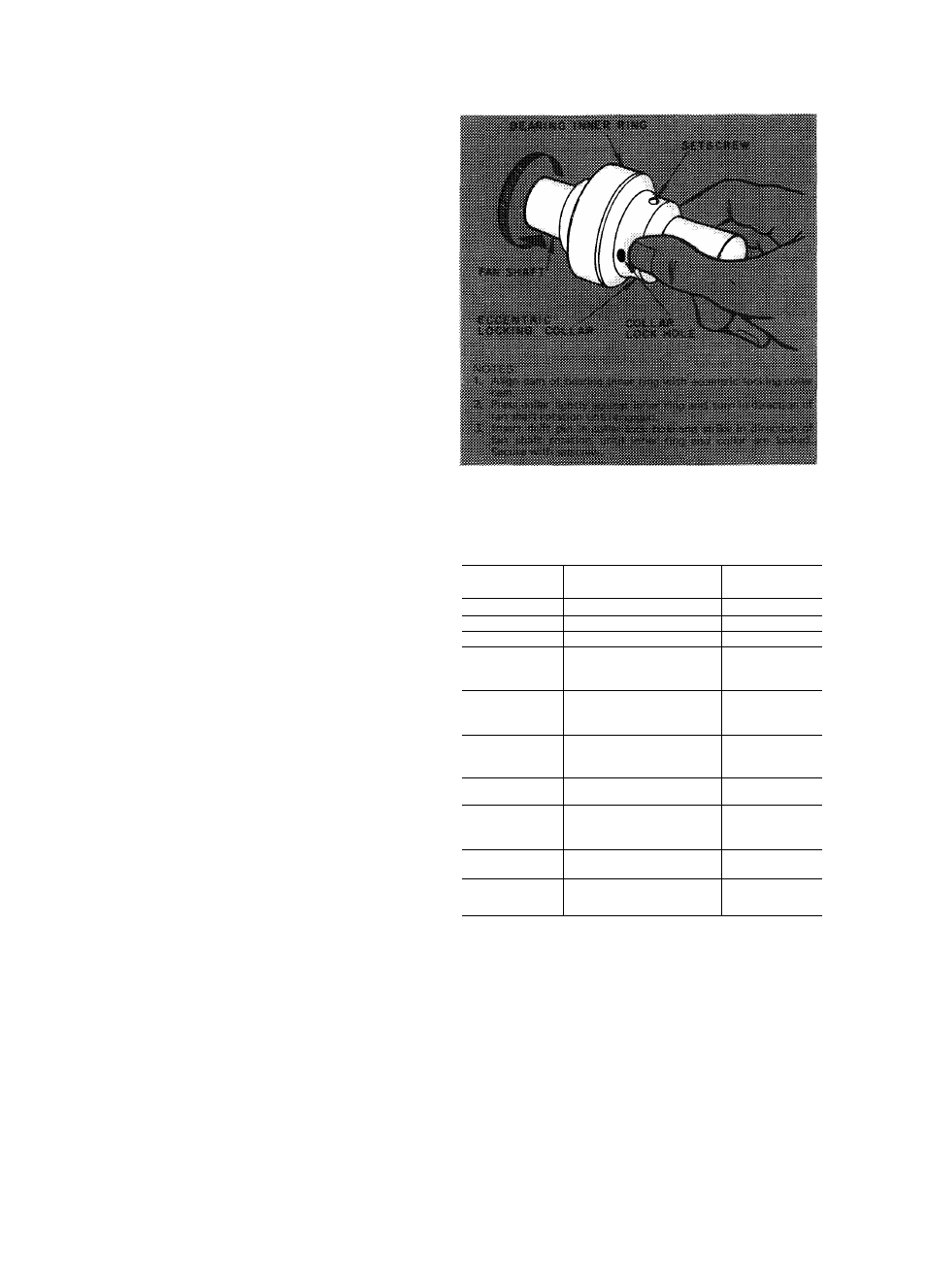

3. Check secureness of bearing locking collars per

Table 4. Refer to Fig. 26 for eccentric type.

Recheck sheave alignment and belt tension.

Make certain fan shaft turns freely and fan

wheels do not rub in housings.

Make certain filters used during building con

struction are replaced with new ones. Refer to

Table 9.

Check direction of rotation and fan speed.

Arrow on fan drive side indicates correct

direction of rotation. Excessive fan speed may

result in condensate carry-over from coohng

cod and/or fan motor overload. Refer to

39B, 39C Operation and Maintenance Instruc

tions for operating Umits.

4.

5.

6

.

7.

Fig. 26 — Securing the Bearing Eccentric

Locking Collar

Table 9 — 39B Filters, 2 Inches Thick,

(No.... Size)

UNIT 39B

LOW VELOCITY AND

MIXING BOX

HIGH

VELOCITY

040

2...16x16

1...16x20

050

2...16x2U

1... 20x25

060

2...20x25

2...16x25

070

2..

. 20x20

2.. . 20x25

2

..16x20

3...25x20

080

ЗИ7Ж20

3

.20x25

3...16x20

6...

16x20

090

'6...2Ux2U

3.. .20x25

3.. .16x20

8...16x20

100

97720x25

3 ..16x20

8

...20x20

105

and

no

3...2D72D~

6

..20x25

9 .16x20

14 .16x20

120

4 ..16x25

14 . 16x25

130

135 and 140

36 ..20x20

36...20x25

24 . 20x20"”"

24 20x25

8. Vibration Check:

NOTE: After final assembly, unit is checked to

ensure vibration level is within tolerance.

If excessive vibration is noted, check following:

Drive alignment

Mismatched belts

Wheel or sheaves loose on shaft

Loose or worn bearings

Loose mounting bolts

Motor out of balance

Sheaves eccentric or out of balance

Vibration isolators improperly adjusted

Worn or corroded wheel (replace if bad)

Accumulation of material on wheel (mate

rial accumulation should he scraped off).

a.

b.

c.

d.

e.

f.

g-

h.

i.

j-

77