Carrier 39B User Manual

Page 13

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

5. Fasten flange 4 to matching flange of applicable

accessory (except bypass heat section arranged

for bypass cooling only) with seven 1/4-20

X

1/2-in. self-tapping screws and locknuts.

6. Fasten flange 4 to matching flange of bypass

heat section arranged for bypass coohng only

as follows:

a.

Line up flange 4 with matching flange of

accessory.

b. Drill seven engagement holes in matching

flange with a no. 3 drill.

c. Fasten flange 4 to matching flange with

seven 1/4-20 x 1/2-in. self-tapping screws.

7. Fasten flange 5 to matching flange of appli

cable accessory or cooHng coil section with

seven 3/8-16 x 3/4-in. hex head cap screws and

matching flange weld nuts.

8. Fasten flange 6 to matching flange of applicable

accessory with seven 3/8-16 x 3/4-in. hex head

cap screws and matching flange weld nuts.

9. Fasten flange 6 to matching flange of coohng

coil section with seven 1/4-20 x 1/2-in. self

tapping screws and matching flange engage

ment holes.

10. Fasten flanges 7 to matching flanges of appli

cable accessory with two 1/4-20 x 1/2-in. self

tapping screws per two flanges and matching

flange engagement holes (bypass duct) or lock

nuts (duct extension or bypass heat section).

11. Fasten flanges 8 to matching flanges of appli

cable accessory or coohng coil section with

five 3/8-16

X

3/4-in. hex head cap screws and

hex nuts per two flanges.

12. Tighten all screws securely.

13. Replace coil in preheat section.

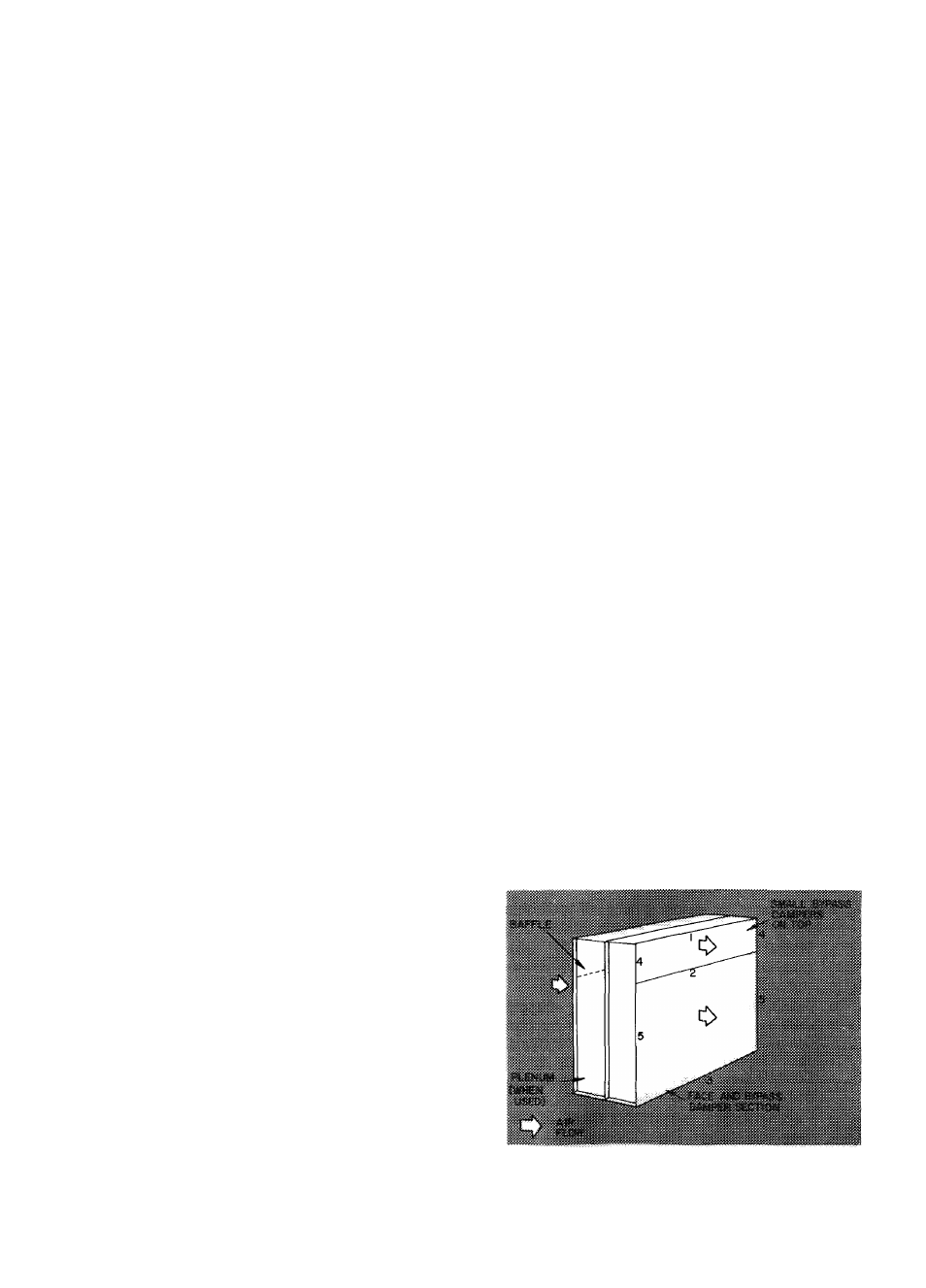

FACE

AND

BYPASS

DAMPER

SECTION

(Size 130 thru 140) - Refer to Eig. 10.

1. FoUow preceding steps 1 and 3.

2. Fasten flange 1 to matching flange of apphcable

accessory (except bypass heat section arranged

for bypass cooling only) with seven 1/4-20

X

1/2-in. self-tapping screws and locknuts.

3. Fasten flange 1 to matching flange of bypass

heat section arranged for bypass coohng only

as follows:

a. Line up flange 1 with matching flange of

accessory bypass heat section.

b. Drill seven engagement holes in matching

flange with a no. 3 drill.

c. Fasten flange 1 to matching flange with

seven 1/4-20 x 1/2-in. self-tapping screws.

4. Fasten flange 2 to matching flange of apph

cable accessory or coohng coil section (preheat

coil section; sizes 135 and 140 excluded) with

seven 3/8-16 x 1-in. hex head cap screws per

flange and matching flange weld nuts.

5. Fasten flange 2 to matching flange of preheat

coil section (sizes 135 and 140) as follows:

a.

Line up flange 2 with matching flange of

preheat coil section.

b. Follow preceding steps 3b and 3c (sub

stitute flange 2 for flange 1 in step 3 c).

6. Fasten flange 3 to matching flange of apphcable

accessory or coohng coil section (preheat coil

and cooling coil sections, sizes 135 and 140

excluded) with seven 3/8-16 x 1-in. hex head

cap screws and matching flange weld nuts.

7. Fasten flange 3 to matching flange of preheat

coil section (sizes 135 and 140) with seven

3/8-16 X 1-in. hex head cap screws and hex nuts.

8. Fasten flange 3 to matching flange of coohng

coil section (sizes 135 and 140) with seven

1/4-20 X 1/2-in. self-tapping screws and match

ing flange engagement holes.

9. Fasten flanges 4 to matching flanges of apph

cable accessory (bypass duct excluded) with

two 1/4-20 X 1/2-in. self-tapping screws and

locknuts per flange.

10. Fasten flange 4 to matching flanges of accessory

bypass duct with two 1/4-20 x 1/2-in. self

tapping screws and matching flange engagement

holes.

11. Fasten flanges 5 to matching flanges of apph

cable accessory or coohng coil section with:

five (accessory or coohng coil section —

size

130);

five

(accessory

section

—

sizes 135 and 140); six (coohng coil section —

sizes 135 and 140) 3/8-16 x 1-in. hex head cap

screws and hex nuts per two flanges.

12. Tighten all screws securely.

13. When face and bypass damper section is used

with accessory humidifier, minimum stops

may be required to ensure air flow thru

humidifier at all times. Install stops on damper

actuator hnkage as opposed to directly on

damper blades to prevent possible damage.

Fig. 10 — Assembly of Accessory Face and Bypass

Damper Section — (Sizes 130-140)

13