Carrier 39B User Manual

Page 15

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

OUTDOOR UNITS — Not recommended for

standard units unless following precautions are

taken into consideration. Consult your local

Carrier representative for units specially factory

equipped for outdoor use.

1. Externally insulate all accessories that are not

factory insulated (combination mixing box and

filter section, filter section, and face and bypass

damper section).

2. If outside temperature will be below dew point

of air in unit at any time during operating

season, insulate complete unit externally to

prevent internal condensation. Vapor seal and

weatherproof insulation.

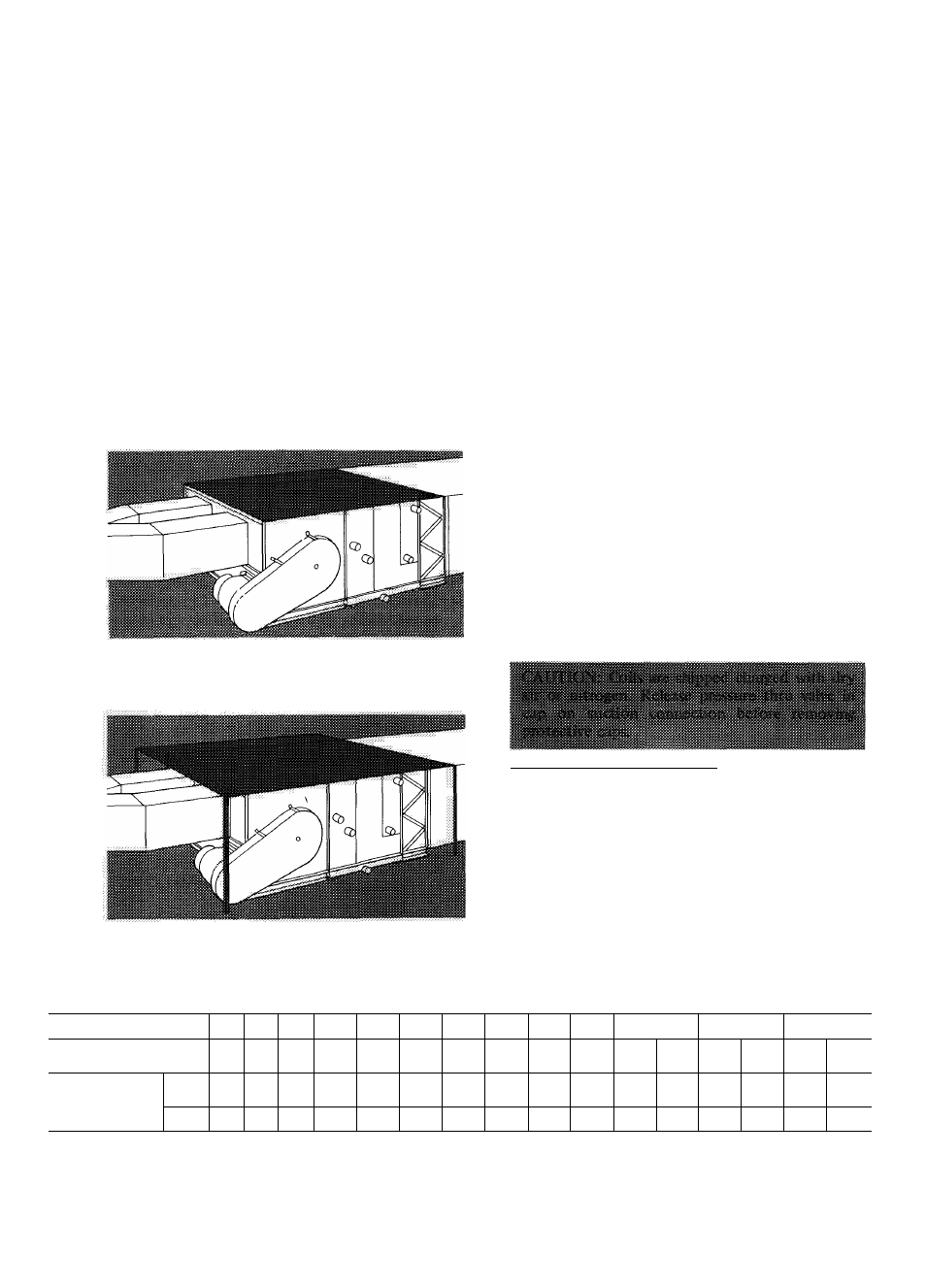

3. Install a crowned waterproof cover on top of

unit to prevent water from collecting or leaking

into unit per Fig. 12. A shed-type cover

(Fig. 13) can be used as an alternate.

Fig. 12 — Crowned-Type Protection Cover —

Field-Supplied

4.

Caulk all joints with nonhardening material

such as butyl-rubber or silicone-rubber to pre

vent moisture infiltration.

5. Install a field-supplied rain shield over outside

air damper of combination mixing box and

filter section.

6. Obtain motor manufacturer’s recommendation

for a fan motor type suitable for outdoor use.

7. Install a field-supphed cover over damper link

age to prevent ice and snow from interfering

with operation. Damper motor must be suitable

for outdoor use.

8. If unit is to be subjected to freezing tempera

tures, insulate condensate drain lines and locate

trap indoors to prevent freeze-up.

9. For coil freeze-up protection, refer to 39B, 39C

Operation and Maintenance Book.

Piping

— Cod connections are labeled on unit.

GENERAL

1. Pipe unit so that vibration is not transmitted to

or from unit.

2.

Allow sufficient clearance for unit piping

connections so that piping will not prevent

removal of fan belt guard.

3. All piping must follow standard piping tech

niques. Refer to Carrier System Design Manual

for details.

DIRECT-EXPANSION COOLING COIL

Fig. 13 — Shed-Type Protection Cover

Field-Supplied

Refrigerant Distributor Nozzles

1.

Check refrigerant distributor nozzle against

design load and note following:

a.

Nozzles installed are for minimum rec

ommended coil loading for proper refrig

erant distribution and oil return. For heavier

loads, proper nozzles must be substituted.

b. Nozzle orifice size is stamped on nozzle.

Refer to Table 5 for factory-installed

standard coil nozzles. Refer to Table 6 for

nozzle orifice capacities.

Table 5 — Factory-Installed Refrigerant Distributor Nozzles — Standard Direct-Expansion Coils

UNIT SIZE

040

050

060

070

080

090

100

105

no

120

130

135

140

Size Coil

In Unit

s

040

050

060

070

080

090

100

130

110

120

130

130

no

130

120

130

Qty-Size

3

Nozzles

In Coil

4- And

6-Row

1-G2

1-G3

1-G4

1-C4

1-C5

2-C5

2-C6

2-C5

2-C6

2-AlO

2-C5

2-C5

2-C6

2-C5

2

-AlO

2-C5

8-Row

1-G2

1-G3

1-G4

1-AlO

1-A12

2

-A

1 2

2

-A

1 2

2

-A

1 2

2

-A

1 2

3-A12

2

-A

1 2

2

-A

1 2

2

-A

1 2

2

-A

1 2

3-A12

2

-A

1 2

1«;