Print approval, Material, Flexcap flc quicklock radius coping – Flex FLC Coping User Manual

Page 25: Quantities

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

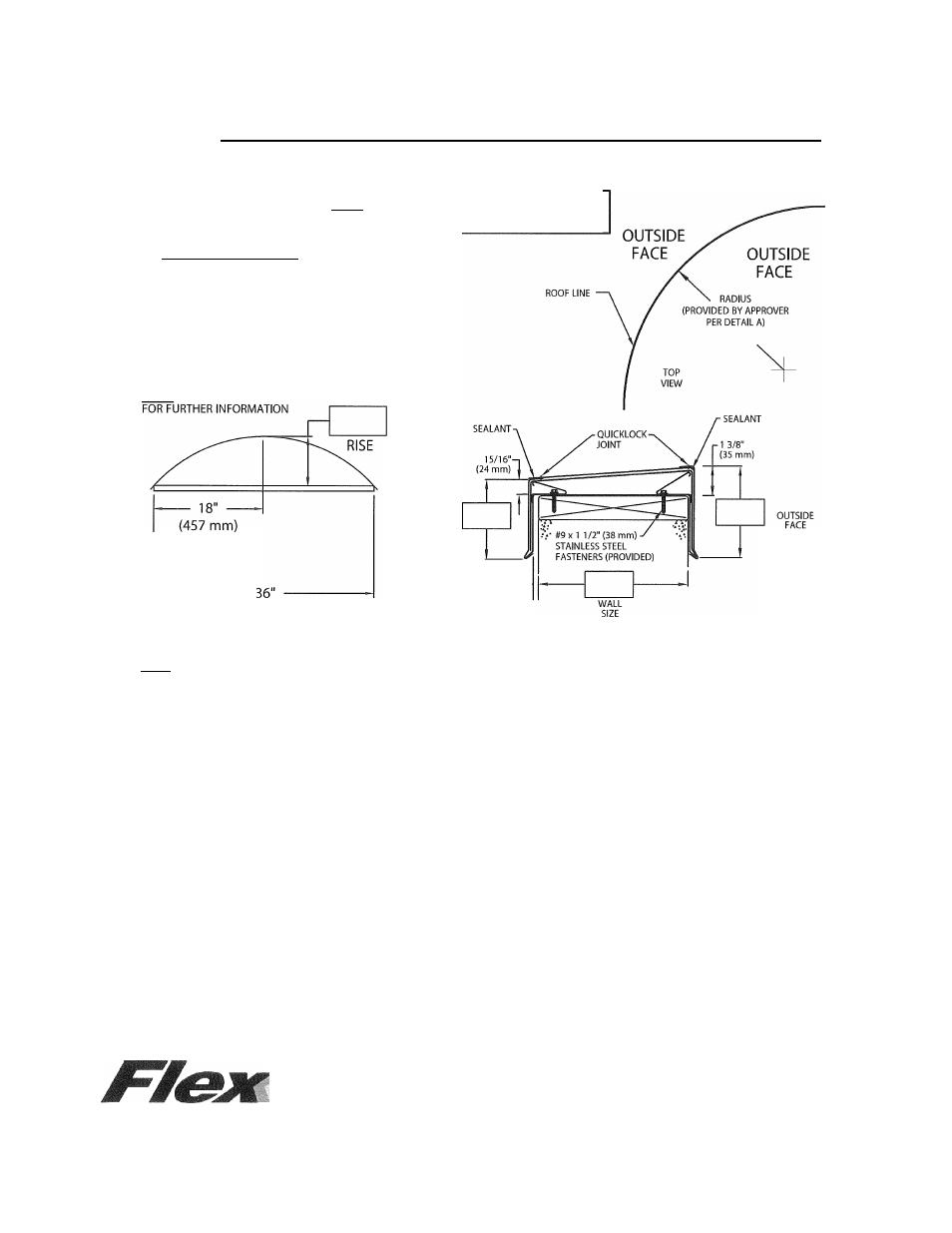

FLEXCAP FLC QUICKLOCK RADIUS COPING

TAPERED VERSION

IMPORTANT!!!

MUST INDICATE PROPER RADIUS CONDITION BY

CIRCLING APPROPRIATE OUTSIDE FACE

PROVIDING A RADIUS

THE RADIUS MAY BE PROVIDED

IN ONE OF TWO METHODS:

1.) THE ACTUAL KNOWN RADIUS IS

OR

2.) FIELD CONDITION MEASUREMENTS

NOTE: REFER TO ATTACHED WORKSHEET

MIDPOINT OF

STRAIGHT EDGE

INSIDE

FACE

MIN. 2 1/4" (57 mm)

MAX. 6" (152 mm)

(914 mm)

LENGTH OF

STRAIGHT EDGE

NOTE: CHECK MEASUREMENTS ALONG ENTIRE RADIUS.

DETAIL A

MIN. 3" (76 mm)

MAX. 6" (152 mm)

%"(10mm) SPACE

PROVIDED FOR

VUALL VARIATION

MOTF^" -- Concealed splice plates are provided with factory

‘ applied dual non-curing sealant strips.

- Fabrication of radius is furnished utilizing a non-penetrating

quicklock joint, then factory sealed watertight.

Fabrication will proceed only after receipt of

signed print approval.

Print Approval:

Architect and/or contractor shall verify all

dimensions, sizes and quantities. All

products to be installed in strict accordance

with Flex's printed instructions.

Approved by:

_____________________________

Date; _______________ __________

MATERIAL:

. 24 Ga. (.65 mm) Steel

. .040" (1.01 mm) Aluminum

. .050" (1.27 mm) Aluminum

. .063" (1.60 mm) Aluminum

Other_________________

Color:

Finish:

QUANTITIES:

.Lineal Feet 4'-0" (1.22 m) Lengths

PROJECT:

ARCHITECT:

ROOFING CONTRACTOR:

REPRESENTATIVE/DISTRIBUTOR:

Customer Service:

Phone: 800^969-0108

Fax:610-916-9501

DATE: 12/13/10

DRN BY: JJC

CKD BY: SAK

SHT.# OF

DWG# 28011-3481

p: 800-969-0108

f: 610-916-9501

print approval

95