Fig. 7 — low-pressure switch (lps) adjustment, Check capacity control system description, Check capacity control system – Carrier 30H User Manual

Page 9

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

HIGH-PRESSURE SWITCH (HPS)

The

HPS

settings

are

nonadjustable.

Table

5

shows the factory settings for this switch.

If the HPS cuts out while the unit is in normal

operation (2-1/2 minutes or more after compressor

start-up), the compressor will stop and lock out. To

restart the compressor, the ON-OFF control circuit

switch must be manually pressed to OFF and then to

ON. The timer will start, and after approximately

5.5 minutes, the compressor will start under Time

Guard control. If the pressure has not dropped to

the HPS cut-in point (see Table 5), the compressor

will stop again immediately and again lock out.

No

further attempts to restart should be made untd the

trouble is found and corrected. Unless the control

circuit switch is pressed to OFF at this time, the

timer will continue to run for approximately 1-1/2

minutes and then stop.

If the control circuit switch is left at ON, the

control

circuit

remains

partially

energized,

includ

ing the timer relay. Consequently, if the pressure

drops to the HPS cut-in point before restart, the

compressor

overtemperature

protector

(COP)

light

will come on. This should not be cause for alarm in

this case since the light is functional only when the

discharge

temperature

thermostat

contacts

open

during normal unit operation.

:

ì

/

г

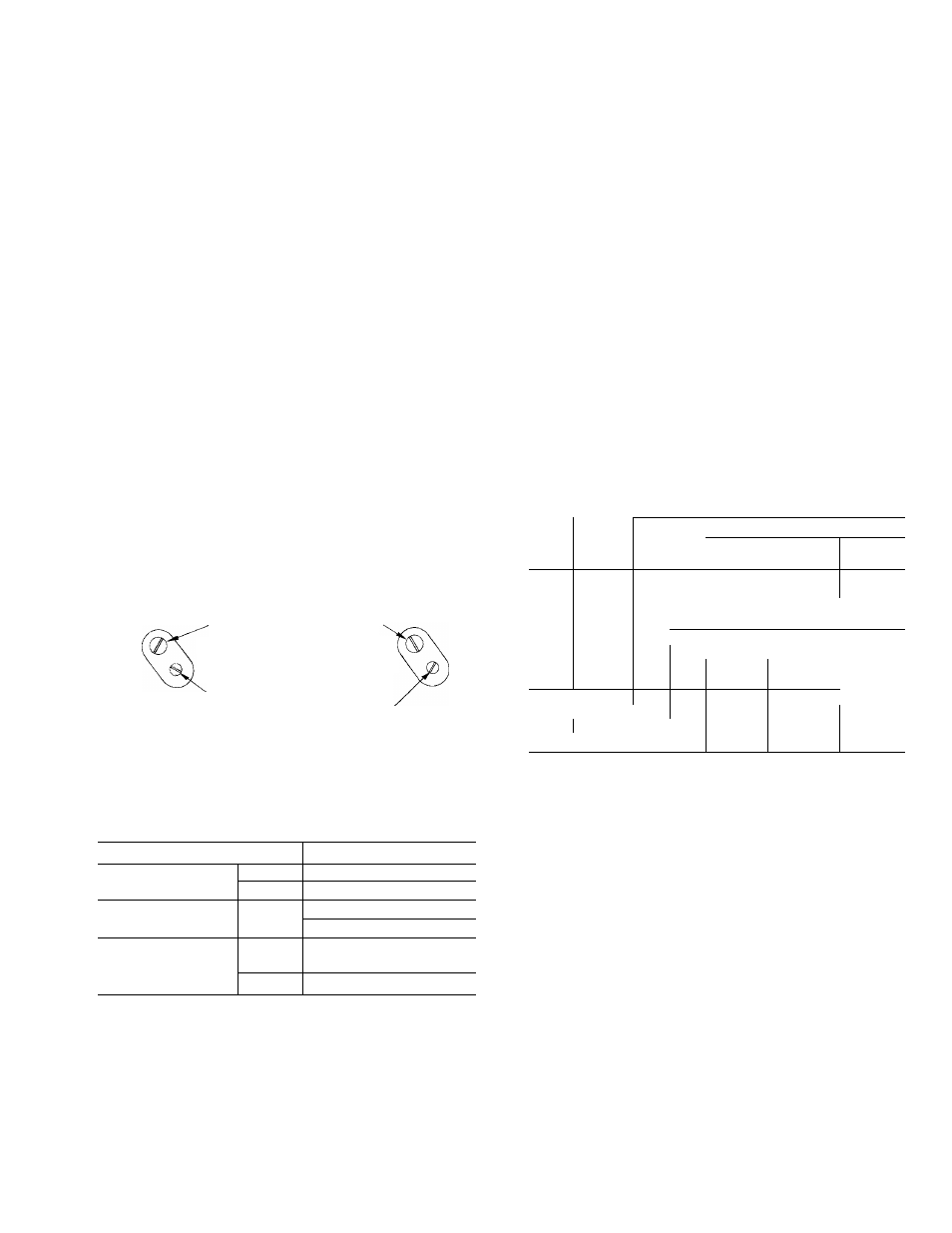

RANGE ADJ SCREW

TURN CLOCKWISE TO RAISE BOTH CUT-IN

AND CUT0UT(7PSI PER TURN),

LPSl

LPS2

DIFFERENTIAL ADJ SCREW

TURN CLOCKWISE TO DECREASE

(8 PSI PER TURN). ONLY CUTOUT CHANGES

(RIGHT SIDE OF CONTROL BOX, VIEWED FROM TOP)

Fig. 7 — Low-Pressure Switch (LPS)

Adjustment

Table 5 — Pressure Switch Specifications

UNIT

зон

PRESSURE

High

Fixed

RANGE (psig)

Low

10 to 90 Adjustable

DIFFERENTIAL

High

103 ±19 (Fixed)

SETTING (psi)

Low

13 to 50 Adjustable

FACTORY

High

Cutout Cut-in

335 ±10 —

SETTING (psig)

Low

29 ±4 1 44 ±4

TOW-PRESSURE SWITCH (EPS)

The

EPS

is

bypassed

for

2-1/2

minutes

after

compressor start on all start-ups.

The EPS has an adjustable range from 10 to 90

psig and a differential of 13 to 50 psi. Table 5 shows

the factory settings for this switch.

If the LPS cuts out while the unit is in normal

operation (any time after 2-1/2 minutes from com

pressor

start-up),

the

timer

starts

and

runs

for

approximately

5.5

minutes.

The

compressor

then

starts, bypassing the LPS for 2-1/2 minutes under

Time Guard® control. If the LPS cut-in pressure is

reached

within

the

2-1/2

minutes,

the

compressor

continues to run; if the required pressure has not

built up, the compressor stops at the end of the 2-1/2

minutes and locks out.

Further attempts to restart the unit must not be

made until the trouble has been found and cor

rected.

The LPS contacts must be closed before the

compressor can be restarted after lockout.

Check Capacity Control System

DESCRIPTION

Capacity control is a system which loads and

unloads compressor cylinders and starts and stops

the compressors to maintain load requirements. The

system

includes

a

4-step

temperature

controller

and cylinder unloaders (see Table 2). Table 6 shows

the capacity control steps.

Table 6 — Capacity Control Steps

SEOUENCE1

SEQUENCE 2

UNIT

CONTR

%

Cap.

Oper Cyl

f

Oper Cyl

ЗОН

STEPS

Tot.

Ckt

Í

Ckt

1 1 2

Cap.

j

Tot.

Ckt i Ckt

1 1 2

1

25

2

2 i —

25 i 2

— i

2

040

2

50

4

2 ; 2

50 i 4

2 ! 2

3

75

6

4 : 2

75 6

2 1 4

4

100

8

4 ; 4

100 : 8

4 ; 4

1

40

4

4 : —

20 : 2

^ ! 2

050

2

60

6

4 , 2

60 : 6

4 : 2

3

80

8

6 ; 2

80 ^ 8

4

i

4

4

100

10

6 i 4

100 10

6 i 4

1

33

4

4 : —

33 1 4

— i 4

060

2

67

8

4 : 4

67 М 8

4 4

3

83

10

6 М 4

83 1 10

4 : 6

4

100

12

6

1

6

100 ! 12

6 ) 6

4-STEP

TEMPERATURE

CONTROLLER

This

controller

consists

of

4

load

switches

actuated by pressures developed in a temperature

sensing bulb located in the return water line of the

chilled water system. The controller is factory set to

control from

return water temperature thru a cool

ing

range

of

10

F.

The

sequence

switches

are

factory calibrated and sealed and should not require

any field changes.

I MPtJR I .AN I: If a different return-water cool

ing range or lea\'in^-\\.atcr control is specified,

or if brine below 10 F'i.s to be used, the controller

must be changed. Consult local Cai’rier rep

resentative for proper control device.

The return water temperature at which the last

step of capacity unloads is indicated by the leaving

water temperature design setpoint on the adjustable

dial (Fig. 8).