Carrier 30H User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

CAUTION; Retìghten all condenser head bolts

before filling system with water. Torque bolts

to 150-170 Ib-ft.

Water leaving condenser is under pressure and

should not be connected directly into sewer lines.

Check local codes. A 3/8-in. drain plug is located in

the head at each end of the condenser.

Refer to Pressure Relief Devices concerning con

nections for these components.

COOLER DESCRIPTION

The cooler is a direct-expansion type with remov

able heads and is partitioned for multi-pass refrig

erant flow. The water flow across the tube bundle

is directed by baffles designed for minimum water-

pressure drop. The tubes have integral internal fins

for maximum heat transfer efficiency.

Viewed from the front of the unit, the chilled

water enters (returns) at the left end of the cooler and

leaves at the right end. The sensing bulb for the

factory-set

water

temperature

controller

is

located

in the return-water nozzle; the return-water tem

perature being the control point. The sensor for the

low

water-temperature

cutout

is

located

in

the

leaving water nozzle.

The cooler is insulated with a flexible, closed

cell

plastic

foam

insulation

of

suitable

thickness.

Water vapor cannot penetrate the cellular structure

to condense either within the cells or on the cooler

shell. Thus, the insulation itself is a vapor barrier.

Because of the toughness of the insulation, a pro

tective sheet metal covering is not necessary.

The standard cooler can be used for all glycol

brines down to -20 F. However, for calcium or

sodium

chloride

brines,

it

is

important

that

the

proper inhibitors be carefully selected for protection

of the copper tubes. Refer to publications of the

Calcium Institute or the Mutual Chemical Division

of

Allied

Chemical

Corporation

for

information

on corrosion control in calcium or sodium chloride

systems.

COOLER PIPING

Plan piping for minimum number of changes in

elevation. Install manual or automatic vent valve at

high points in line. Maintain system pressure by

using a pressure tank or combination relief and

reducing valve.

See

Carrier

System

Design

Manual,

Part

3,

Piping Design, for chilled water piping detials.

Install

thermometers

in

entering

and

leaving

water lines. Provide drain connections at all low

points

to

permit

complete

drainage

of

system.

Connect shutoff valve to drain line before operating

unit.

Install

shutoff

valves

near

entering

and

leaving

water

connections.

Use

flexible

connections

to reduce vibration transmission.

Insulate piping

after leak testing to prevent heat

transfer and sweating. Cover insulation with mois

ture seal.

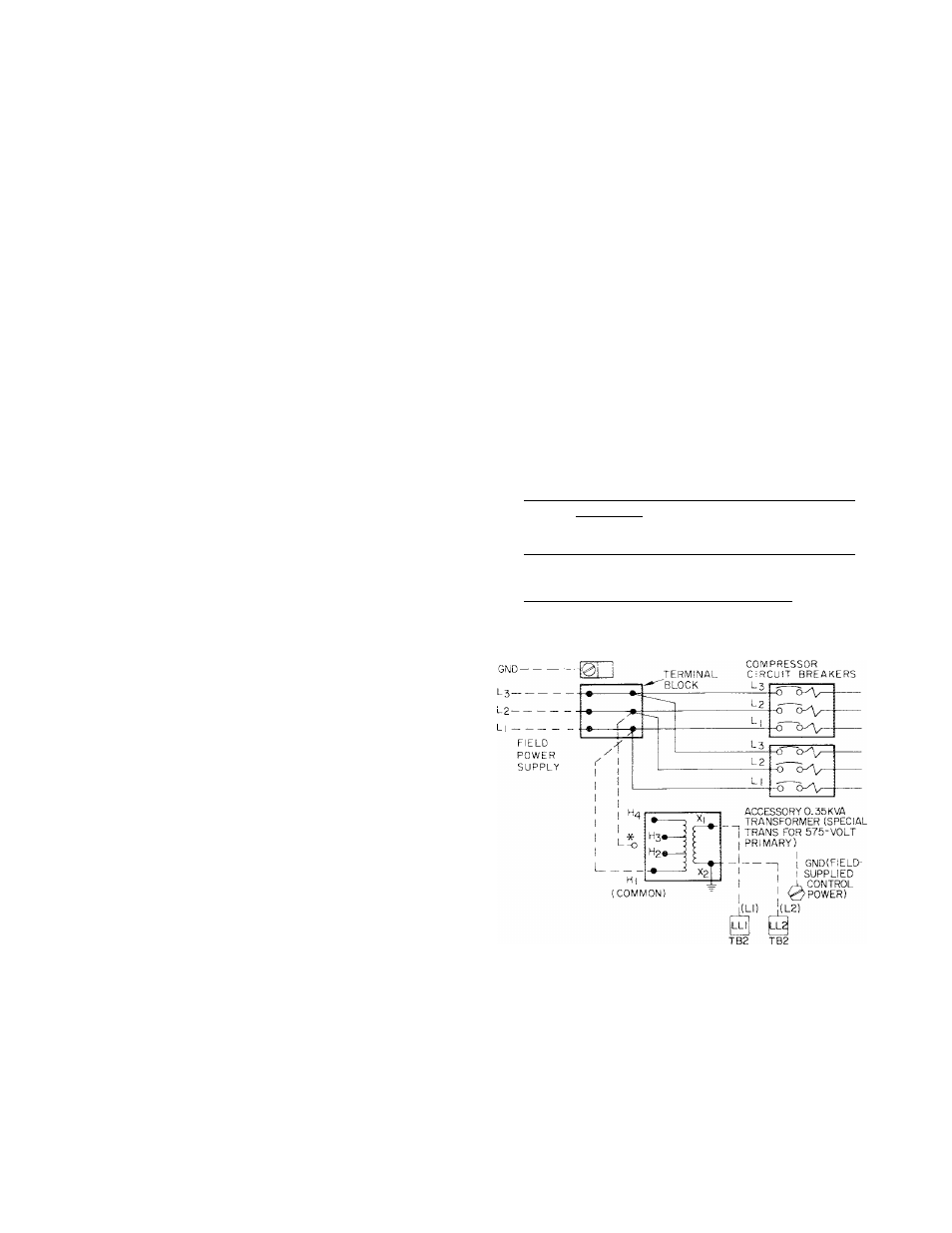

All field wiring must conform with local code

requirements.

Control

circuit

is

115

volts

on

all

60-Hertz

units.

Accessory

transformer

package

is

available to allow 115 volts to be taken directly from

unit terminal block (see Fig. 3). Installation instruc

tions are furnished with the accessory package. Con

trol power may also be supplied from a separate

source thru a 15-amp fused disconnect.

Inside

the

control

box,

provision

is

made

to

connect the ground wire which must be installed

with each field power supply.

All units are factory supplied with across-the-line

start at all voltages.

Refer to Table 4 for electrical data on individual

compressors

and

complete

units

and

compressor

usage.

LABEL DIAGRAMS

The applicable Label Diagrams for the 30H040,

050,060 Heat Reclaim units are the same as for the

standard 30HK040,050,060 units.

Table 3 — Unit Voltage and Model Number

Step 5 — Make Electrical Connections

UNIT

30H

VOLTS

230 i

Model*

460

575

200

.....

040

! 420

: 520 1

620

120

050

i 420

520 ‘

620

> 120

060

420

520 I

620

120

*Last 3 digits of complete mode! number.

EQUIP GND

WHEN CONTROL CIRCUIT POWER IS FROM SEPARATE SOURCE

INCOMING WIRES ARE CONNECTED DIRECTLY TO

TERMINALS

LL!

AND

LL2

ON TB2.

±2

MUST BE

CONNECTED TO NEUTRAL (GROUND) POTENTIAL.

CB

— Circuit Breaker

EQUIP GIMD — Equipment Ground

TB

— Terminal Board

*Appropriate

transformer

terminal

depends

on

unit

voltage,

instructions with accessory transformer package. H2 = 200 v;

H3 = 230 v; H4 = 460 v.

NOTE: For grounding 1 1 5-voit control circuit when transformer is

used, see instructions with accessory transformer package.

Fig. 3 — Wiring Schematic — Unitand Control

Power Supply