Table 7 — plugs and tubes, Tightening cooler head bolts – Carrier 30H User Manual

Page 12

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

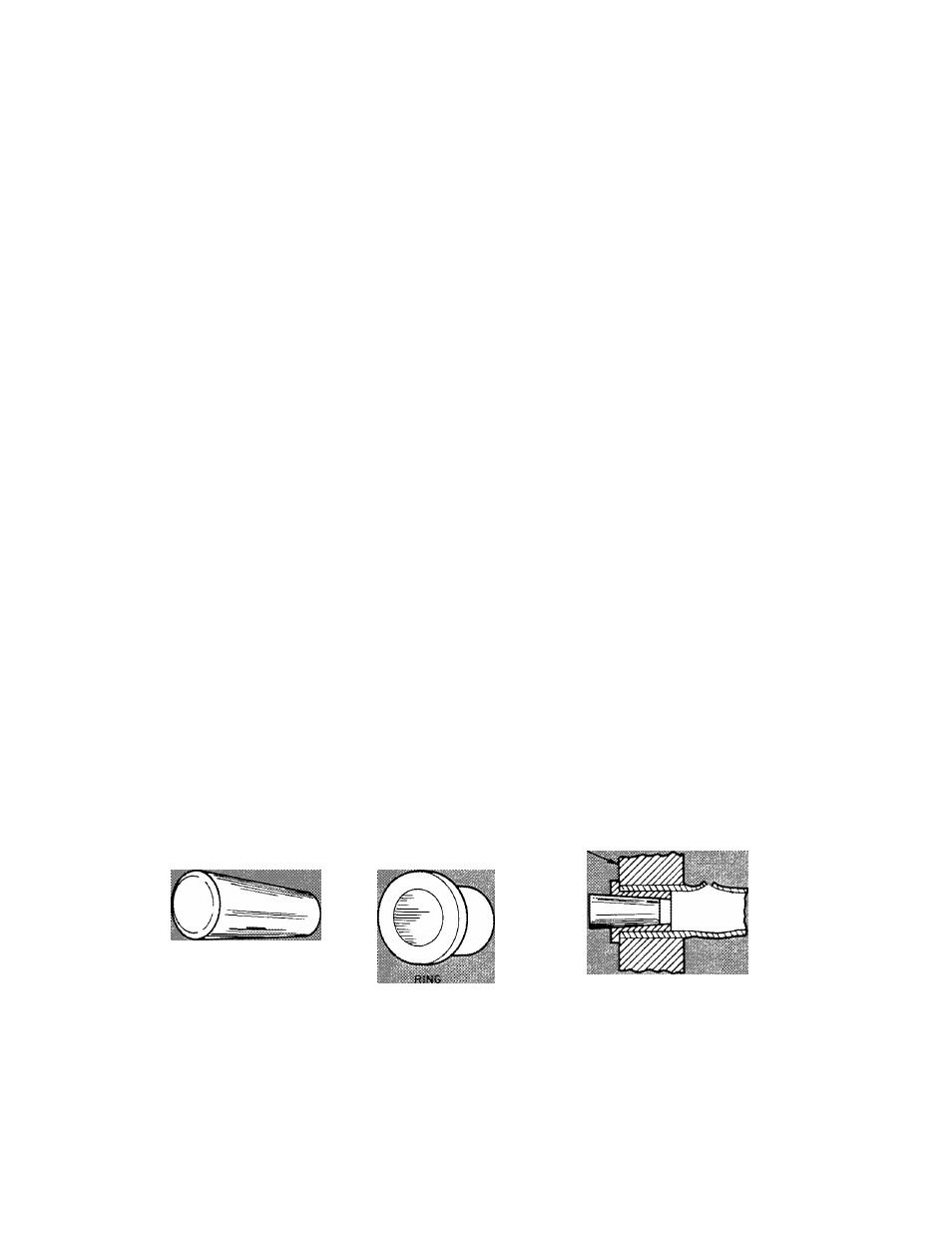

Tube Plugging

— A leaky tube(s) can be plugged

until retubing can be done. The number of plugged

tubes

determines

how

soon

the

cooler

must

be

retubed.

If

several

tubes

require

plugging,

check

with your local Carrier representative to find out

how

the

number

and

location

will

affect

unit

capacity.

Figure 12 shows an Elliot tube plug and a cross-

sectional view of a plug in place. Table 7 lists the

components for plugging.

C.MJ I'lON; Use extreme care when installing

plugs to prevent damaging the tube sheet sec

tions between the holes.

Clean parts with Loequie “N” and apply a few

drops of Loctite #75 to obtain a tight seal without

using too much force to set the pin.

Usually plugs can be removed by heating the pro

jecting end of the pin to approximately 1000 F and

chilling

quickly

with

water.

Apply

the

heating

flame to the side of the pin to prevent overheating

the tube sheet.

Retubing

(see Table 7) — When retubing is to be

done,

obtain

the

service

of

qualified

personnel,

experienced in boiler maintenance and repair. Most

standard

procedures

can

be

followed,

except

that

for the tubes in the ЮНА coolers, a 5% crush is

recommended

in

setting

torque

control

(5/8-in.

diameter tubes are used in these coolers).

Example;

a. Tube sheet hole diameter......................................... 630 in.

b. Tube OD ................................................................... 625 in.

c. Clearance (a minus b)...............................................005 in.

d. Tube ID before rolling

(Use Elliot tube gage)................................................551 in.

e. 5% of twice the wall thickness

(5% of b minus d)..................................................... 004 in.

f. Tube ID after rolling

(c + d + e)................................................................... 560 in.

Table 7 — Plugs and Tubes

UNIT зон

PLUGGING

For Tubes

Brass Pin

Brass Ring

For Holes without Tubes

Brass Pin

Brass Ring

Loctite

Loequie

040

050, 060

PART NUMBER

853103-500*

853002-559*

853103-1*

853002-631*

No. 75f

"N”t

TUBE DATA

Part No.

Length (in.)

OD (in.)

Wall Thickness (in.)

Plain End

Finned Section

SPECIFICATION

10HA501043

74.50

0.625

0.037

0.025

10HA501053

85.50

0.625

0.037

0.025

*Order directly from Elliot Co.

Lagonda Operation

Springfield, Ohio

fCan be obtained locally.

Tightening Cooler Head Bolts

GASKET PREPARATION

When

reassembling,

use

new

gaskets.

Com

pressed

asbestos/neoprene

gaskets.

Carrier

Material Specification ZAOO-24, are to be

momen

tarily dipped in compressor break-in oil prior to

assembly. Gaskets are

not to be soaked in oil as

gasket deterioration results. Dipped gaskets are to

be used within 30 minutes to prevent deterioration.

BOLT TORQUES

The following torques are to be applied during

the bolt tightening sequence described below:

5/8-in. diameter flange b o l t s . . . . 150 - 170 Ib-ft

1 / 2-in. diameter center-stud nuts and

1 / 2-in. diameter flange bolts....................... 70 - 90 Ib-ft

TUBE SHEET

>0 A

Fig. 12 — Elliott Tube Plug

12