Laries are not rubbing against anything, Step 4 — make piping connections – Carrier 30H User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

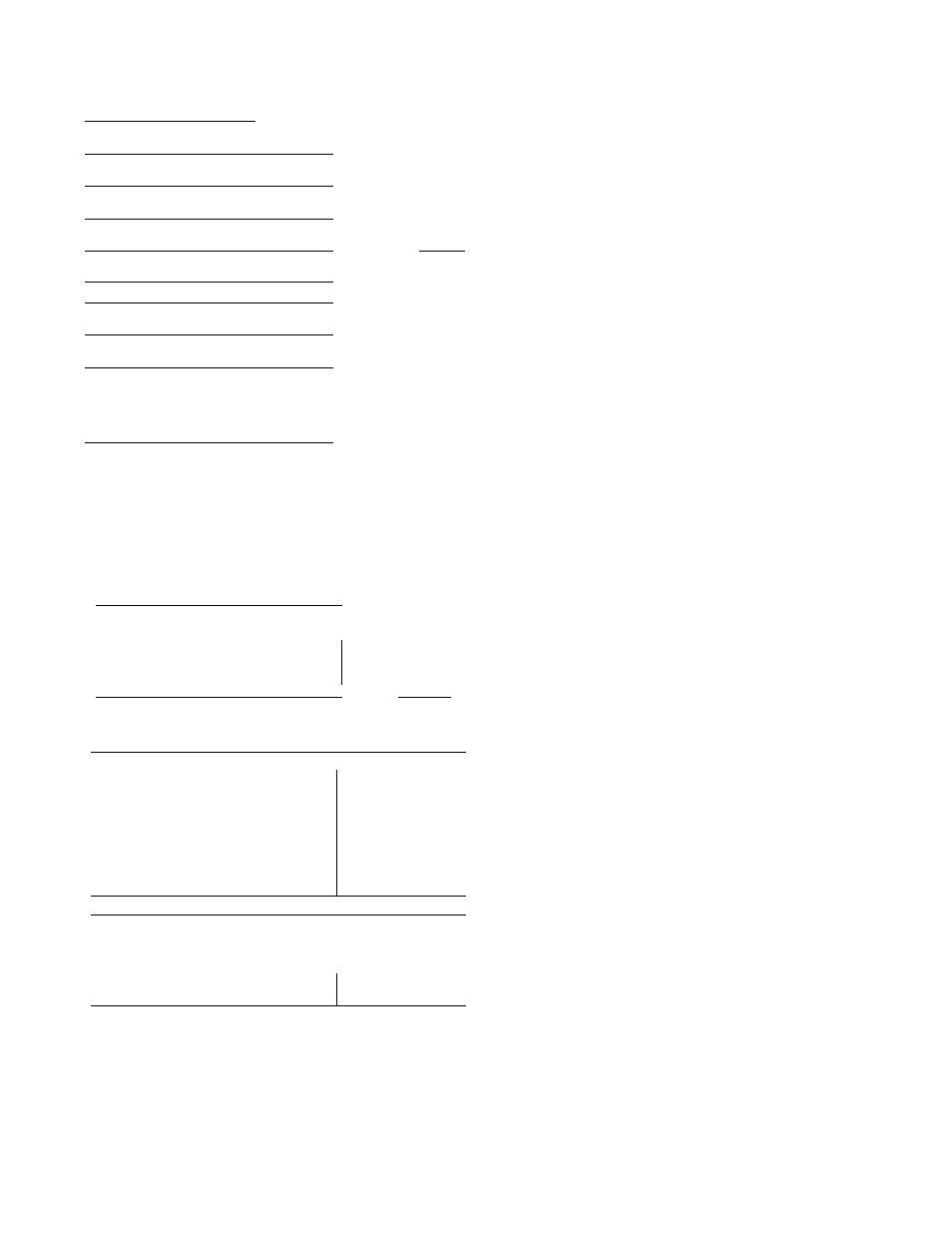

COMPLETE UNIT

Tabie 2 — Physical Data

UNIT ЗОН

040

050

060

APPROX OPER WT (lb)

:3930

4310

4440

REFRIG CHG, R-22 (lb)

Ckt 1

52

■ 62

62

Ckt 2

52

: 52

62

COMPRESSOR 06E

Ckt 1

B250

J275

J275

Ckt 2

B250

B250

J275

Cylinders/Compressor

Ckt 1

4

6

6

Ckt 2

: 4

4

6

Unloaders/Compressor

Ckt 1

^ 1

1

1

Ckt 2

' 1

1

1

Oil Chg Per Compressor (pt) Ckt 1

14

19

19

Ckt 2

' 14

14

19

Capacity Control Steps

: 4

4

4

TOWER CONO, 09RP

Ckt 1

022

027

027

Ckt 2

022

; 022

027

HEAT RECLAIM COND, 09RP Ckt 1

022

Ckt 2

022

MAX DESIGN WORK. PRESS, (psig)

Cooler 1

Water Side

150

Refrig Side

235

Tower Condensers j

Water Side

250

Refrig Side

385

COOLER

COOLER, 10HA400

unît

зон

SHELL, Net Volume (gal.)

1^

040

13.1

154

TUBES

050, 060

..

iCopper,

Internai Fins

00 X Wall Thickness (in.)

5/8 X

0.025

Number

129

129

Length (in.)

74.5 5

85.5

Effective Outside Surface Area (sq ft) i

126.6 )

146.0

REFRIG CIRCUITS

CONNECTIONS (in.)

2

2

X (In and Out

Water ir-. •

(Drain

3

3/4

3

3/4

1.125

1.125

1.625

2.125

CONDENSERS

CONDENSER 09RP (See Note)

022

027

TUBES

Copper, Interna! Fins

OD (in.)

Wall Thickness (in.)

3/4

Plain End

.042

Finned Section

.028

Length (in.)

70-5/32

Fins/in.

40

Number Tubes*

36 ! 44

Surface Area (sq ft)

1 Inside

iOutside

32.9 ‘ 40.2

133.6 163.4

NO. WATER PASSES

3

CONNECTIONS (in.)

I Inlet (IPS)

1 Outlet (IPS)

2-1/2

2-1/2

Relief Valve Outlett (SAE)

5/8

Liquid Outlet (OOF)

t

7/8

Hot Gas (OOF)

1-3/8

*!n Tower condensers, 5 of the tubes are

n subcooling section.

tNot on Heat Reclaim Condensers.

NOTE:

Heat

Reclaim

Condensers

same

as

Tower

Condensers

except

where

noted.

The

bottom

outlet

of

each

Heat

Reclaim

Condenser is same size as Hot Gas connection.

C .'\r flON; He Mire ip-lcreunnuciiti!: pipi,ni.;ind

electrical conduits are suspended free of contact

with ar.y adiacent walls and be sure taiit capil

laries are not rubbing against anything.

SERVICE ACCESS

Remove the combination top and back cover over

each compressor. Servicing can be performed from

either top or back. For rear access, allow approxi

mately 3 ft of clear space behind unit.

Step 4 — Make Piping Connections

CONDENSER DESCRIPTION

In the 4-condenser bundle, the lower

2 are Tower

and the upper 2 are Heat Reclaim. All are shell and

tube type with removable heads for easy tube servic

ing. Each Tower condenser has an internal sub

cooler designed to provide 12 F to 15 F total

liquid

subcooling

at

average

tower

water

condi

tions. The Heat Reclaim condensers do not require

subcooling,

therefore,

the

subcooler

baffling

is

removed.

For

further

condenser

data,

refer

to

Table 2 — Physical Data.

TOWER CONDENSER PIPING

Provide means for draining system in winter and

for maintenance.

iMPOR r.\N 1 ; Ci):!üc!>er wa'.ur nvj'.t a;

the bottom for proper operation of the internal .

subcooler, which is in the bottom of the con

denser (Fig. 1).

Water supply lines should be sized according to

the required flow rate for operation at design con

ditions (not necessarily connection size). Use flexi

ble connections to reduce vibration transmission.

A cooling tower bypass valve is usually used to

regulate the temperature of the water entering the

condensers. This may be controlled by sensing either

outdoor

air

temperature

or

temperature

of

water

leaving

the

Heat Reclaim condensers. For further

information on Systems Controls, refer to the Engi

neering

Guide

for

Reciprocating

Chiller

Heat

Reclaim Systems.

HEAT

RECLAIM

CONDENSER

PIPING

Normally, the piping is for series water flow thru

the condensers. Piping to and from the condensers is

connected to the heating system of the building.

Piping for parallel water flow thru the condensers is

used only when the cooling load is constant at all

times. For further piping information, refer to the

Engineering

Guide

for

Reciprocating

Chiller

Heat

Reclaim Systems.

Figure 1 shows connections for series piping thru

the Heat Reclaim condensers.