Unit operation, Servicing the cooler, Servicing the cooler ,12 – Carrier 30H User Manual

Page 11

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

UNIT OPERATION

Control Power

(115 volts) can be from a separate

source, thru a 15-amp fused disconnect or can be

taken from the main unit power source, thru a field-

supplied transformer as shown on the wiring label.

Control Sequence

— At initial start-up, assume

all safety devices are satisfied and the chilled water

temperature controller switches are all in position

for maximum cooling capacity.

Close the compressor circuit breaker and press the

control circuit ON-OFF switch to ON. Timer no. 1

starts and, depending on the position of the timer,

compressor no. 1 starts in approximately 12 seconds

to 8 minutes. At compressor start-up, the D-D 1 con

tacts

(see

Four-Function

Timer

and

Fig.

4)

are

closed, bypassing the low-pressure switch for 2-1/2

minutes. In addition, the E-El contacts are closed,

bypassing the oil safety switch (if used) for approxi

mately 35 seconds. Both these bypass functions are

protection against the compressor continuing to run

under conditions that could cause damage to the

compressor.

Barring

any

malfunction,

when

the

timer

contacts

A-A2

close,

approximately

2-1/2

minutes after start-up, timer no.

I

stops and timer

no. 2 starts. In approximately 12 seconds to 8 min

utes, compressor no. 2 starts. Timer no. 2 completes

the same cycle as timer no. ! and stops. Unit is now

in

normal

operation,

with

both

compressors

running.

The temperature controller regulates the cooling

capacity by loading and unloading compressor cyl

inders and stopping and starting the compressors

under Time Guard® control, in response to load

requirements.

Complete Unit Stoppage and Restart

— After

each possible cause for unit stoppage is a short

description of the normal method of restart.

1. CONTROL POWER INTERRUPTION (IN

CLUDES BLOWN FUSE).

After power is restored, or fuse replaced, restart

is automatic thru normal timer cycle.

2. CONTROL CIRCUIT ON-OFF SWITCH IS

OPENED.

When the switch is opened, the timer motor starts

automatically,

runs

for

approximately

5-1/2

minutes

and

stops.

To

restart,

press

ON-OFF

switch to ON. In approximately 12 seconds, com

pressor starts.

3. CONTACTS OF ANY AUXILIARY INTER

LOCK ARE OPEN.

After trouble has been corrected, restart is auto

matic thru normal timer cycle.

4. LOW WATER TEMPERATURE CUTOUT

CONTACTS ARE OPEN.

Allow water temperature to rise 5 F; then press

control circuit ON-OFF switch to OFF and back

to ON. This restarts the timer. Unit restarts auto

matically thru normal timer cycle.

5. CONTROL CIRCUIT FUSE BLOWS.

Check for possible cause; then replace fuse. Re

start is automatic thru normal timer cycle.

6. CHILLED WATER FLOW STOPS.

Locate

and

correct

cause.

When

water

flow

resumes, unit restart is automatic thru normal

timer cycle.

Individual Compressor Stoppage and Restart

1. LOW-PRESSURE SWITCH (LPS) OPENS.

Reset

and

restart

are

automatic,

thru

normal

timer cycle, unless refrigerant charge is very low

or lost. In this case, increase the charge to

normal level before restart.

2.

HIGH-PRESSURE

SWITCH

(HPS)

OPENS.

Press

RESET

button

to

reenergize

the

open

circuit. Restart is thru normal timer cycle.

3.

DISCHARGE

TEMPERATURE

SWITCH

OPENS.

Press

RESET

button

to

reenergize

the

open

circuit. Restart is thru normal timer cycle.

4.

OIL

PRESSURE

SAFETY

SWITCH

OPENS.

Press

RESET

button

to

reenergize

the

open

circuit. Restart is thru normal timer cycle.

IMPORTANT:

If stoppage by

a

safety device

repeats

once,

do

not

attempt

another

restart

until

the cause is

determined and corrected.

Refer

also

to

the

Troubleshooting

section

for

additional information on unit malfunctions.

SERVICING THE COOLER

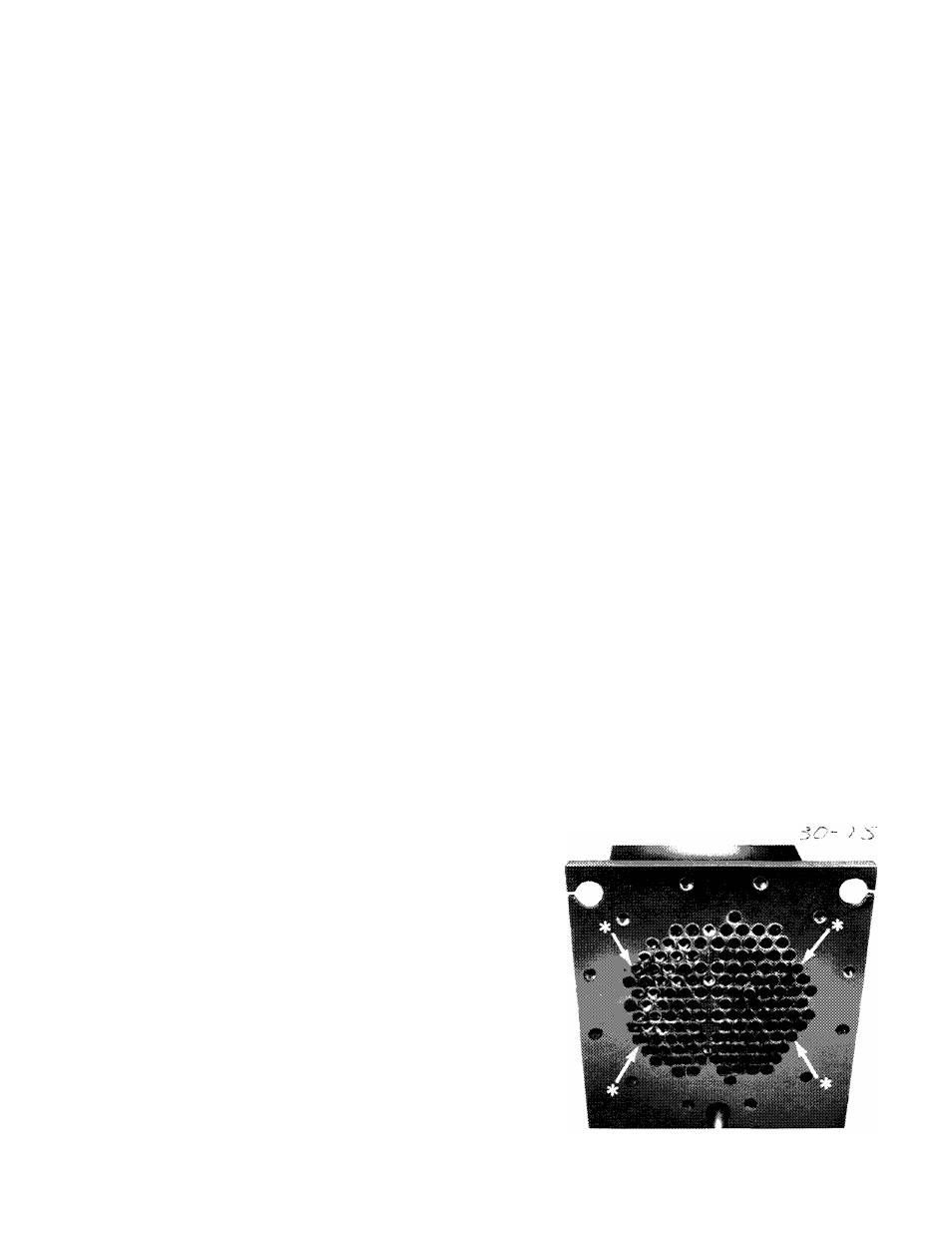

When the cooler heads and partition plates are

removed, the tube sheets are exposed showing the

ends of the tubes as seen in Fig. 11. Four tubes in

the bundle are secured inside the cooler at the

baffles and

cannot be removed. These are identified

on the tube sheets by a drill mark horizontally

adjacent to each of the 4 tubes.

If leakage occurs in

any of these 4 tubes, plug the tube as described under

Tube Plugging.

‘Four fixed tubes (cannot be removed) identified by adjacent

drill points.

Fig. 11 — Typical Tube Sheet

1 1