Carrier – Carrier 26H User Manual

Page 30

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

26H

S E R V I C E

Carrier

Portable Line Voltage Tester

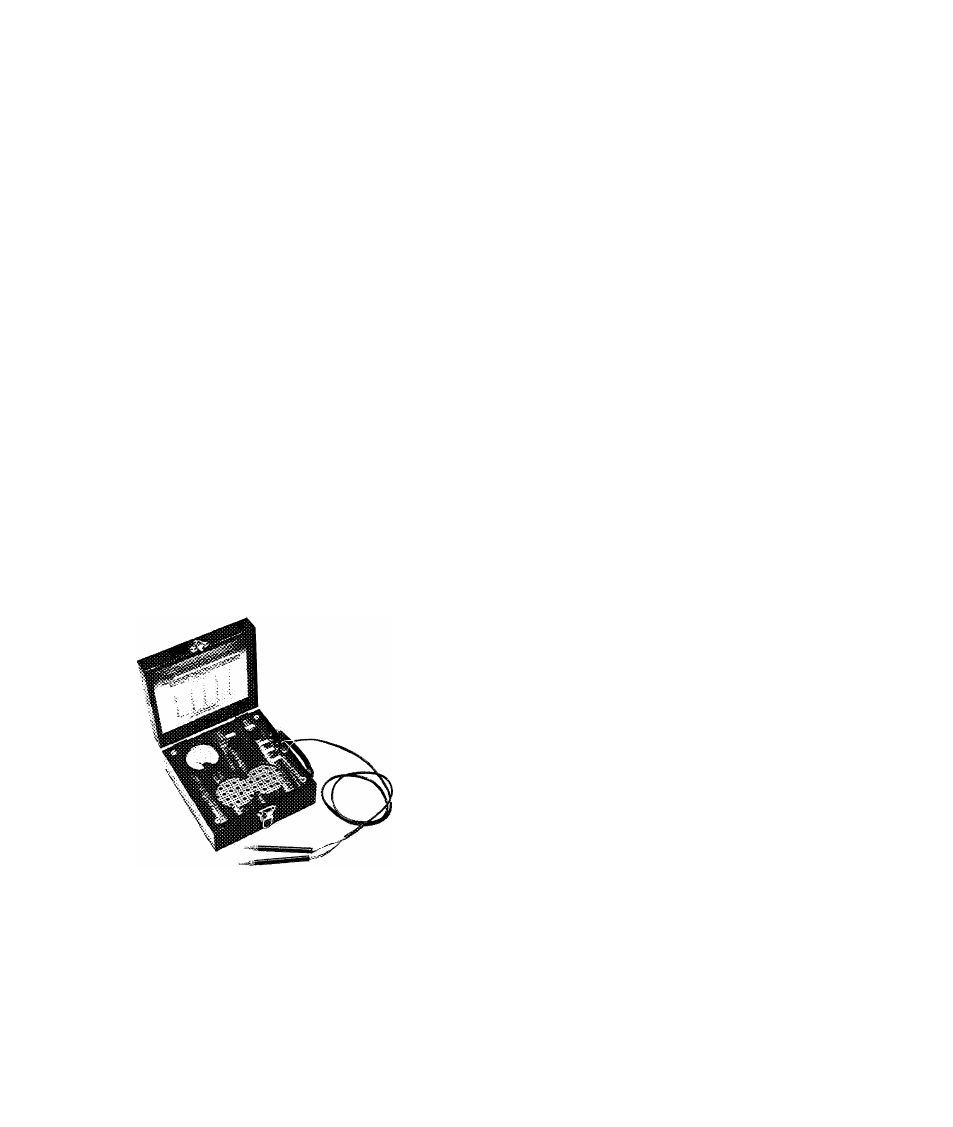

APPLICATION AND OPERATION - A portable line

voltage tester with built-in phantom load which

provides a simple means of checking single phase

or direct current circuits is shown in Fig. 14. By

reading the voltage at no load and the voltage with

phantom load it can be determined if the circuit is

adequate for starting and operating the unit. The

tester is made to Carrier specifications and includes

a table for use with ice cube makers.

PHYSICAL DATA

Case Size

Voltmeter Scale

Ampere Load

Voltage

F requency

Approx. Weight

8"x 8"x 4"

0-150 volts (Double Reading for

230V)

11.5

115 - 230

25, 50, 60 cycles or direct current

5 pounds

Order Directly from

J. & W. Company 290 Roycroft Blvd., Buffalo 21, N.Y.

FIG. 14 - VOLTAGE TESTER

COMPRESSOR REPLACEMENT 26H3

To replace the compressor use the following pro

cedure:

1. Purge the refrigerant charge and then front-

seat both shutoff valves. Disconnect the suc

tion line flare nut at the shutoff valve. Seal

the suction line with a 1/2" plug to prevent

moisture from entering the system.

2. Cut the discharge line and sweat in a 1/4"

SAE male copper to flare connection. Cap this

connection to prevent moisture from entering

the system.

3. Disconnect the compressor leads at the se

lector switch and thermostat.

4. Remove the four compressor mounting bolts

and lift the compressor from the unit.

5. Seal all openings on the compressor to pre

vent moisture from entering prior to repair or

exchange.

6. If compressor failed due to motor burnout, see

"Replacement After Motor Burnout".

7. Install the replacement compressor. The re-

placemsat compressor is shipped with the dis

charge line fastened to the suction shutoff

valve gauge portby means of a 1/4" flare nut.

8. After completing all wiring and piping con

nections evacuate and purge the replacement

compressor.

9. Charge the unit with refrigerant 12. See Sec

tion 4.

10. Before leaving the unit check for leaks.

COMPRESSOR REPLACEMENT 26H5

To replace the compressor, follow this procedure:

1. If the compressor is in running condition,

pump down as explained in Section 3.

•2. If the compressor is not in running condition

close the suction, discharge and oil return

shutoff valves and then slowly bleed pressure

thru the discharge gauge plug.

3. Check to see that both shutoff valves are

f rontseated and unbolt them from the com

pressor. Leave the valves connected to the

piping.

4. Disconnect the high pressure line from the

discharge side of the compressor.

5. Close the water supply valve and disconnect

the compressor cooling coil. The replacement

compressor comes supplied with this coil.

26H-57PD

30