Table 1 — physical data – Carrier 48HDT User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

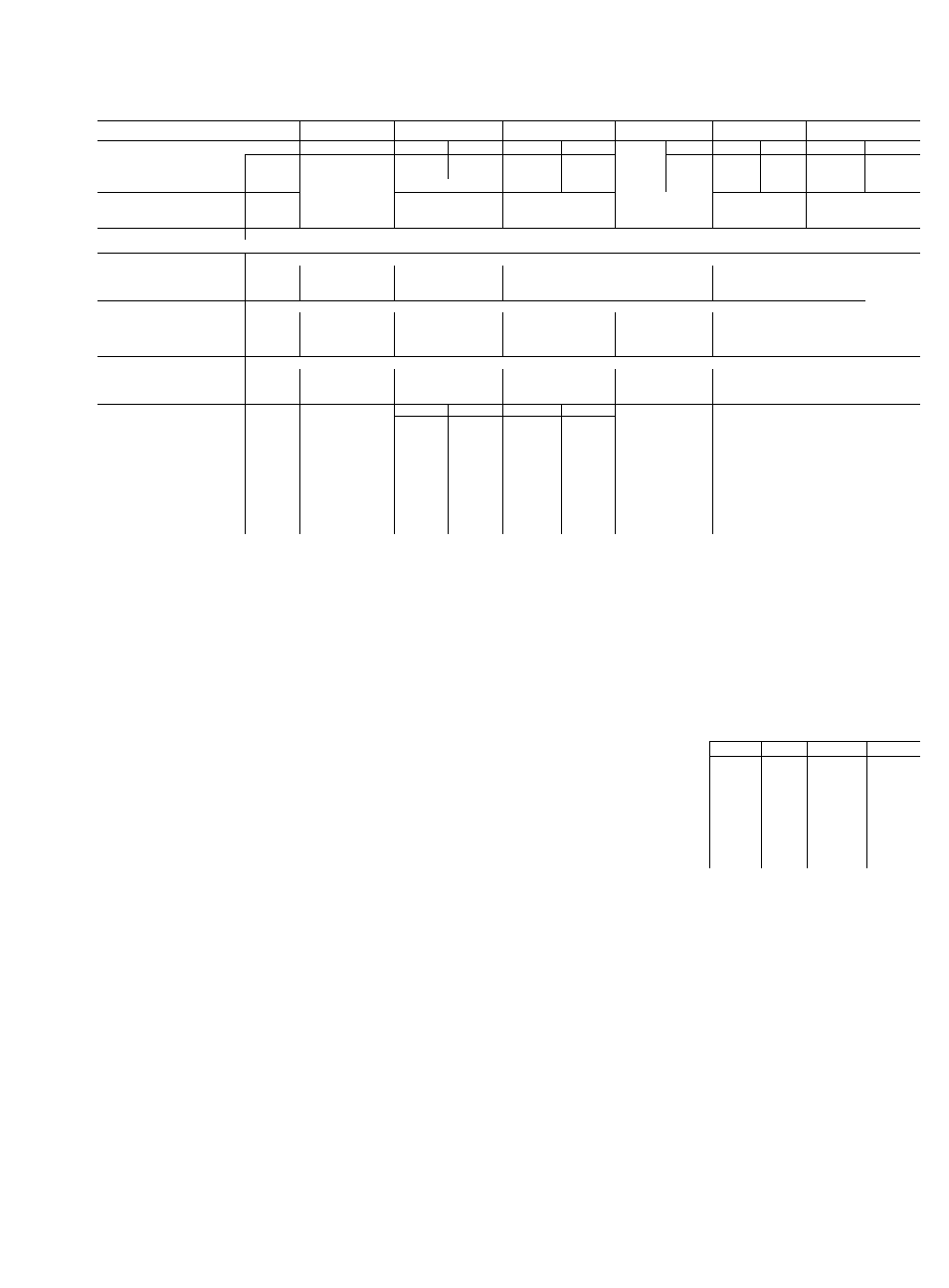

Table 1 — Physical Data

UNIT SIZE 48 SERIES

004

005

006

006

007

008

008

OPER W T (lb)

LDT

HDT ] LDT

HDT

LDT

HH

LH

HD

HH

HD.HH

LD.LH

HDD.HLD

LDD.LHD

Unit

630

650 630

660

640

660

640

720

720

890

886

945

941

with Econom izer

655

675 1 655

685

665

—

—

745

_

950 (HD)

946 (LD)

1005(HDD)

996 (LDD)

Roof Curb

130

130

130

—

—

130

—

125 (HD)

125 (LD)

125 (HDD)

125 (LDD)

COMPRESSOR

Qty Type

1 M4023E

1 P53260

1 P6026B

1 P60-6-

1 P77

1 Hermetic

2 P46

Oil (oz)

42

66

66

74

74

124

124

REFRIG (R-22)

Capillary Contre

Charge (lb)

61

48

72

7 2 I 9 3

9 9

6 2 per system

COND COIL

Copper Tube, Aluminum Plate Fins

Rows

2

2

2

:

2

Fins/in

170

170

140

14 0

140

139

Total Face Area (sq ft)

6 3

6 3

9 73

9 73

108

15 6

COND FAN

Propeller Type

Nom Cfm

2200

3100

3800

3800

4000

4500

Qty Diam (in )

1 22

1 22

1

22

1

22

1

22

22

Motor Hp

%

’/2

’/2

’/2

'/2

’/2

Motor Rpm

850

1075

1075

1075

1075

1075

EVAP COIL

Copper Tube, Aluminum Plate Fins

Rows

2

2

3

A

3

Fins/in

140

140

140

140

140

13 9

Total Face Area (sq ft)

5 33

5 33

5 33

5 33

6 3

8 2

EVAP FAN

HDT

LDT

HH

LH

Qty Size (in )

1 10x10

1 10x10

1 11x10

1 11x10

1 11x10

1 11x10

1 11x10

1

12x12

Type

DD

DD

DD

DD

BD

DD

BD

BD

Nom Cfm

1200

1500

2000

2000

2000

2000

2200

3000

Motor Hp Std

'/3

3/4

1

3/4

’/2

3/4

3/4

1 0

Opt

3/4

—

—

1

3/4

1

1

1 5

Nom Motor Rpm

—

—

—

—

1725

_

1725

—

Std/Opt Low

800/ 890

890

1000

890/1000

__

890/1000

_

High

850/1050

1000

1130

1050/1130

—

1050/1130

—

Rpm Range Std

—

—

—

—

630- 960

-

796- 130

838-1032

(@

2 turns open)

Opt

—

—

—

—

796-1130

—

930-1260

352-11 27 (@ 1 turn open)

Motor Pulley

Pitch Diam

(in )

Std

Opt

Std

Opt

Std

Opt

Fan Pulley

Pitch

Diam

(in )

Belt. Qty Type. Length (in

Speed Change per Full

Turn of Moveable

Pulley Flange (Rpm )

Moveable Pulley

Max Full Turns

from Closed Position

Factory Setting

Std

Full Turns Open

Opt

Factory Speed Setting Std

(Rpm )

Opt

1 9-2 9

2 4-3 4

5 2

5 2

66

66

2

2

830

995

2 4-3 4

2 8-3 8

5 2

5 2

1 A 43

66

66

2

2

995

1130

2 4-3 4

2 4-3 4

50

5 0

65

69

4

4Y2

907

885

FURNACE SECTION

Tem p Rise (F)

Heating Input (Btuh)

Output Cap (Btuh)

Burner Orifice Diam

(in . drill size)

Natural Gas

Pilot Orifice Diam

(in drill size)

Natural Gas

Therm ostat

Heat

Anticipator

Setting

460v

208/230V

LDT

HDT

30-60

80,000

61,600

35-65

120,000

92,400

LDT

HDT

LDT

HH

LH

HD

30-60

80,000

61,600

35-65

1 20,000

92,400

30-60

80,000

61,600

35-65

120,000

92,400

30-60

80,000

61,600

35-65

120,000

92,400

HH

35-65

120,000

92,400

HD.HH

LD.LH

HHD.HDD

LDD.LHD

35-65

203,000

160,370

15-45

114,000

91,200

35-65

203,000

160,370

15-45

114,000

91,200

132 29

113 33

132 29

113 33

036 64

033 66

036 64

033 66

1 2

1 0

1 2

1 0

HIGH-PRESS SW ITCH

Cutout (psig)

Reset (psig)

426 ± 7

320 ± 20

LOW -PRESS SW ITCH

(Suction Line)

Cutout (psig)

Reset (psig)

27 ± 4

67 ± 7

27 ± 4

67 ± 7

AIR INLET SCREENS

Qty. Size (in )

1 32

x

19

x

V2

RETURN AIR FILTERS

Qty Size (in )

1 16

x

25

x

1

1...

20x25x1

2 16

x

20

x

1

2 20

x

20

x

1

DD — Direct Drive

#