Carrier 48HDT User Manual

Page 21

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

If Chargemaster® charging device is used, tem

perature and pressure readings must be accom

plished using the charging chart.

Main and Pilot Burners — At the beginning of

each heating season, inspect for deterioration or

blockage due to corrosion or other causes. Observe

the pilot and main burner flames and adjust, if

necessary, referring to automatic Pilot Adjustment

or Main Burners sections of instructions.

Flue Gas Passageways — Inspect flue collector

box and upper areas of heat exchanger cells by

removing burner compartment access panel; then

remove flue cover and inspect heat exchangers.

Using a wire brush, clean all surfaces as required.

Combustion Air Blower — Clean periodically to

assure proper airflow and heating efficiency. Inspect

blower wheel every fall and periodically during

heating season. For the first heating season, inspect

blower wheel bimonthly to determine proper clean

ing frequency.

To inspect blower wheel, remove draft hood and

screen. Shine a flashlight into opening to inspect

wheel. If eleaning is required, remove motor and

wheel as follows:

1. Remove burner access panel.

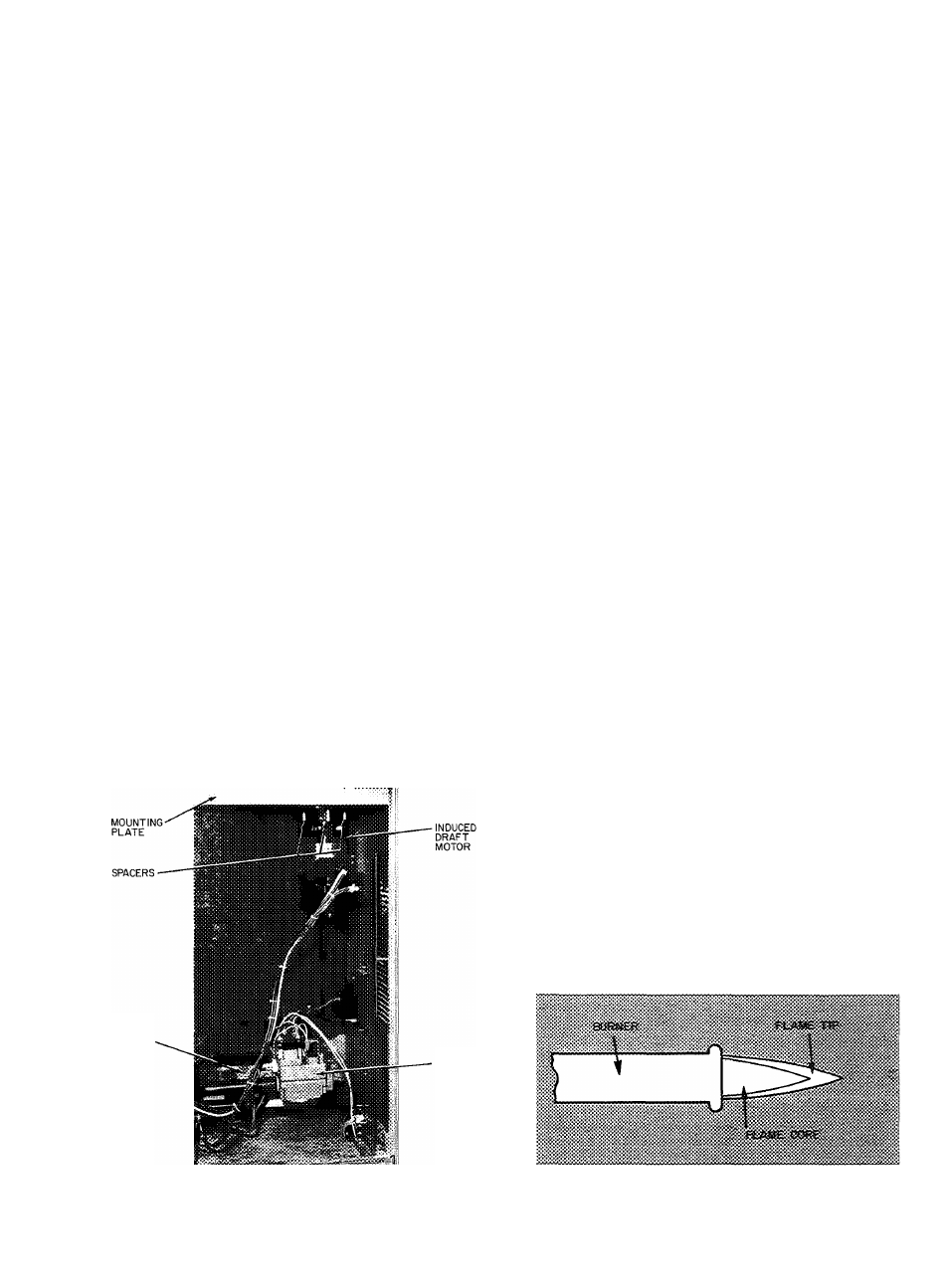

2. Remove the 6 screws that attach induced draft

motor mounting plate to blower housing

(Fig. 42). The mounting plate will drop down.

3. Remove the 4 wires attached to the motor and

remove assembly from unit.

4. To remove blower, remove setscrews.

5. To remove motor, remove blower, then remove

the nuts that hold motor to mounting plate.

NOTE; Do not lose spacers for induced draft

motor.

6. To reinstall, reverse the procedure outlined

above.

MAIN

BURNER

SECTION

MAIN

GAS

VALVE

Limit Switch — Aceess panel is located on the heat

section side panel (Fig. 3 and 4).

004,005,006,007 UNITS AND 48HDD,LDD/HD,

LD008 UNITS — Limit switch is located in the

upper section of the heat exchangers. Bi-metal

sensor is facing the airstream. Remove bracket

holding limit switch and remove screw holding

switch.

48HHD,LHD/HH,LH008 UNITS ^ Limit switch

is located on partition between blower section and

heat section. Remove plate and screw holding

switch.

Pilot Light — If pilot does not light as described in

Start-Up, Heating: Be sure pilot orifice is not

obstructed, gas pressure is not less than 3in. wg;

and air has been bled from gas supply. Check for

spark ignitor malfunctions as follows:

1. Shut off unit power supply.

2. Check that spark gap is 1/8 to 3/16 inch.

3. Check that spark generator is securely grounded

to furnace vestibule plate.

4. Check that high-voltage lead is securely con

nected between generator and electrode body.

5. Restore power. Check that 24 volts is supplied to

primary side of generator.

6. Check unit label diagram for correct terminal

usage if any wires are removed.

Automatic Pilot Adjustment

1. Turn off unit power supply, set system selector

switch at HEAT, and adjust thermostat to call

for heat.

2. Remove burner compartment access panel.

3. Remove screw cap cover on the top of the main

gas valve to expose pilot adjusting screw.

4. With a small screwdriver, turn adjustment screw

until flame is approximately 1 to 1-1/2 in. high.

5. Replace screw cap cover on pilot gas valve.

6. Observe burner operation and adjust main gas

valve for correct burner operation as required.

See Fig. 43 for proper flame appearance.

7. Replace all panels.

Automatic Gas Valve Sequence of Operation

— Thermostat calls for heat, energizing the spark

ignitor and simultaneously opening the pickup and

hold solenoids of the pilot gas valve (inside main gas

valve). The pilot gas ignites within 2 seconds, stop

ping the ignitor. Within 11 seconds, the pilot contact

(normally closed) opens, drops out the pickup sole

noid. Within 35 seconds, the pilot contact (normally

Fig. 42 — Burner Section Details

Fig. 43 — Proper Flame Appearance

21