Fig. 36 — cooling charging chart; 48ldt004, Fig. 37 — cooling charging chart; 48hdt,ldt005, 483 iij l – Carrier 48HDT User Manual

Page 19: O 90

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

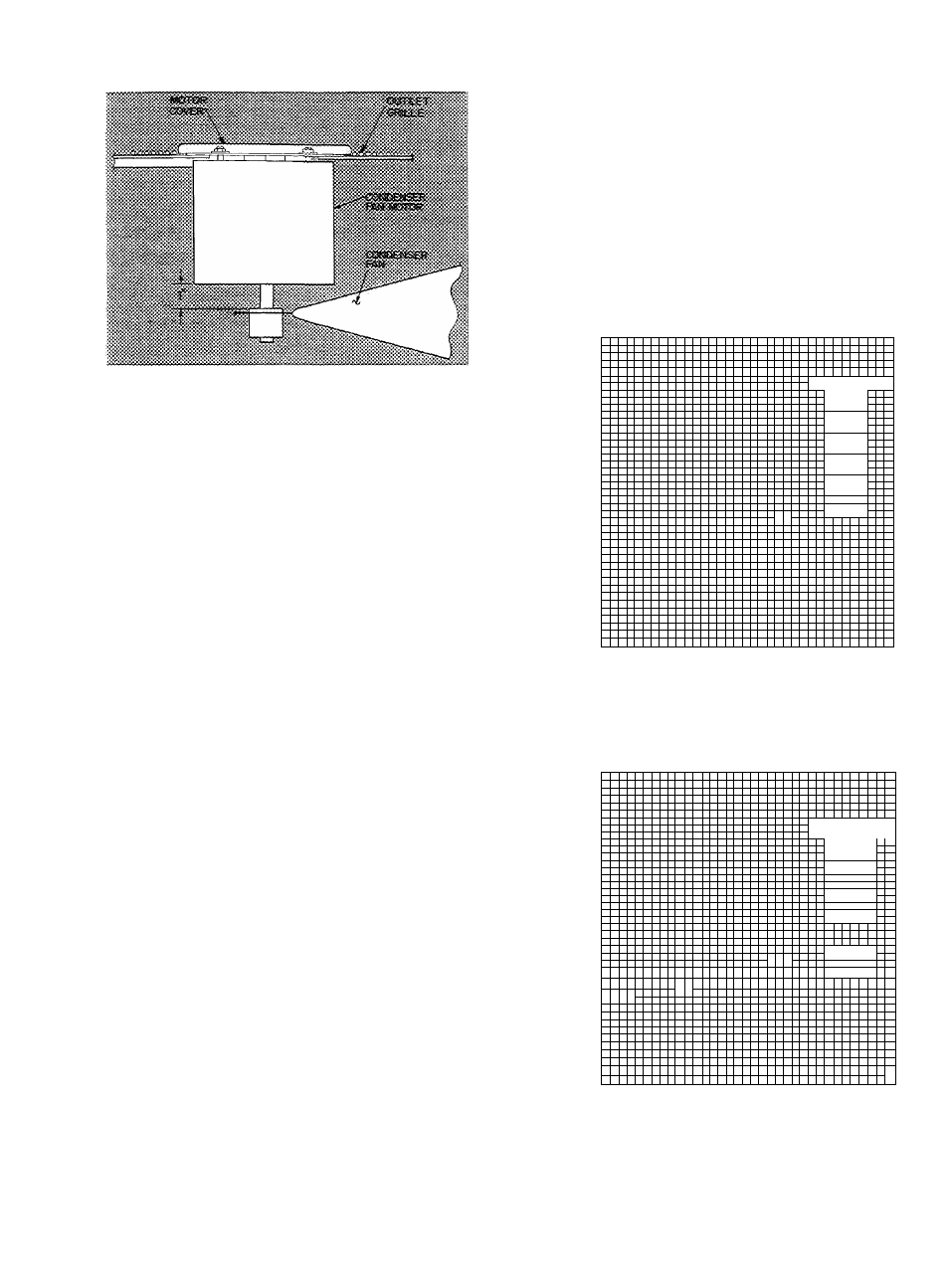

Fig. 35 — Condenser Air Fan Adjustment

Lubrication

COMPRESSORS — Each compressor is charged

with correct amount of oil at the factory.

FAN MOTOR BEARINGS — No lubrication of

condenser or evaporator fan motors is required for

first 5 years of operation. Annually thereafter, clean

and repack bearings with a suitable bearing grease.

Condenser Air Fan Adjustment (Fig. 35) — Shut

off unit power supply. Remove condenser fan

assembly (grille, motor, motor cover and fan) and

loosen fan hub setscrews. Adjust fan height as

shown in Fig. 35. Tighten setscrews and replace

condenser fan assembly.

Manual Outdoor Air Damper (Downshot Units

Only) — If outdoor air damper blade adjustment is

required, see Optional Manual Outdoor Air

Damper Section.

Economizer Adjustment (Downshot Units) —

Refer to Economizer section under Installation.

Refrigerant Charge — Amount of refrigerant

charge is listed on unit nameplate (also refer to

Table 1). Refer to Carrier Standard Service Tech

niques Manual, Chapter 1, Refrigerants.

Unit panels must be in place when unit is oper

ating during charging procedure.

NO CHARGE — Use standard evacuating tech

niques. After evacuating system, weigh in the speci

fied amount of refrigerant. (Refer to Table 1.)

LOW CHARGE COOLING — Using Cooling

Charging Chart, Fig. 36 through 41, vary refrigerant

until the conditions of the chart are met. Note the

charging chart is different from type normally used.

Chart is based on charging the units to the correct

superheat for the various operating conditions.

Accurate pressure gage and temperature sensing

device are required. Connect the pressure gage to the

service port on the suction line. Mount the tempera

ture sensing device on the suction line and insulate it

so that outdoor ambient temperature does not affect

the reading. Indoor air cfm must be within the

normal operating range of the unit (maximum 3750;

minimum 2250).

TO USE COOLING CHARGING CHART ^

Take the outdoor ambient temperature and read the

suction pressure gage. Refer to chart to determine

what suction temperature should be. If suction tem

perature is high, add refrigerant. If suction tempera

ture is low, carefully blow some of the charge. Re

check the suction pressure as charge is adjusted.

Example; (Fig. 40)

Outdoor Temperature........................................... 85 F

Suction Pressure............................................. 70 psig

Suction Temperature should be............................52 F

(Suction Temperature may vary ± 5 F.)

(A

<

O

g 620-

Q

l

O

=i

^

551

iii

tr

§483

iij

L.

: 345

276

o 90

80

60

50

207

30

OUTDOOR TEMP

(F) (C)

115 46

105 41

95 35

85 29

75 24

1 1 1 1

65 18

20

30

40

50

60

70

SUCTION LINE TEMPERATURE (F)

-I

4

10

16

21

SUCTION LINE TEMPERATURE (C)

Fig. 36 — Cooling Charging Chart;

48LDT004

<

w620

<

0

.

o

551

]

483

^414

:345-

276-

80

? 70

60

50

40

207

30

(F) (C)

115 46

105 41

1 1 1 1 1

Mi tr

95 35

M i l l

8 5 2 9

7 5 2 4

1 1 1 1 1

6 5 1 8

20

3 0

40

50

60

70

SUCTION LINE TEMPERATURE (F)

-I 4

10')

16

21

SUCTION LINE TEMPERATURE (C)

Fig. 37 — Cooling Charging Chart;

48HDT,LDT005

19