Service notes, Valve when, Rumnwg – Carrier 06E User Manual

Page 8

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

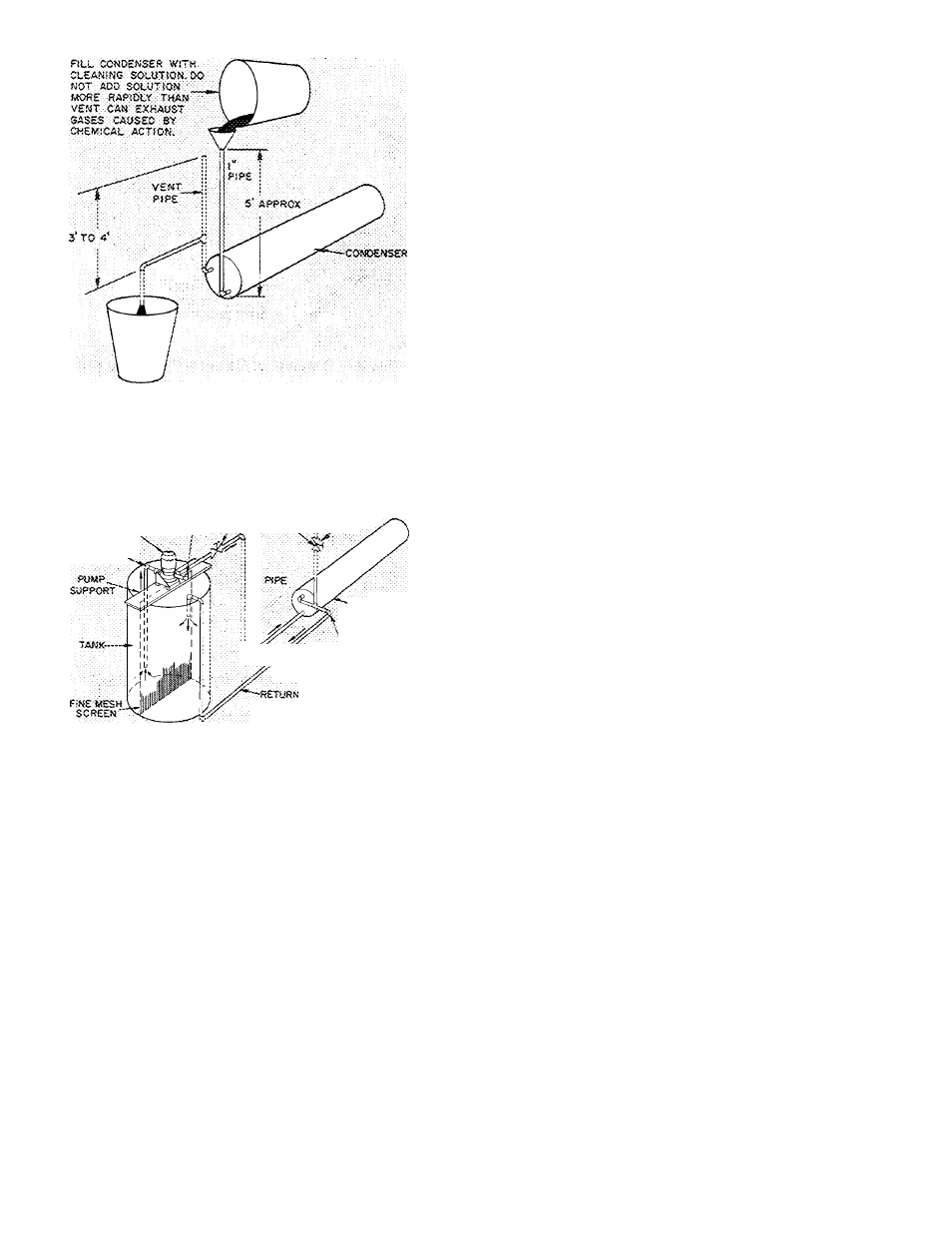

Fig. 10 — Gravity Circulation

ceOTarcGAt.

pcwp

sas

vemt

-

30 OPM AT 35' HEAD

PRl«WS /VAl.VE£\..

PUMP. • "

^

SUCT:ON

: ClXSt VENT PIPE

;

VALVE WHEN

; PUMP IS

:

RUMNWG

COiv-CEAiSES

,

REMCA'E WATER

^

REGULATINC-

valve

Fig. 11 — Forced Circulation

REMOVING, INSPECTING AND

REPLACING COMPONENTS (Fig. 12)

Service Notes

1. All compressors have interchangeable valve

plate assemblies, unloader valves and oil pump

bearing head assemblies. For replacement items

use Carrier Specified Parts.

2. Before compressor is opened, the refrigerant

must be removed from it by the Pumpdown

method.

Start compressor, close suction shutoff

valve, and reduce crankcase pressure to 2

psig. (Jumper low pressurestat.)

Stop compressor and isolate from system by

closing discharge shutoff valve.

Bleed any residual refrigerant. Drain oil if

necessary.

3. After disassembly, clean all parts with solvent.

Use mineral spirits, white gasoline or naptha.

a.

c.

4.

5.

Before assembly, coat all parts with compressor

oil and clean and inspect all gasket surfaces.

Replace all gaskets with new factory-made

gaskets. See Table 4 for torque values.

After reassembly, evacuate compressor and

open suction and discharge valves. Restart

compressor and adjust refrigerant charge.

Legend (Fig. 12)

1 -

Compressor Motor —

29

-

Bottom Cover Plate

Stator and Rotor

30

—

Pump End Bearing

2 -

Motor Key

Head Package

3 -

Rotor Plate Washer

31

-

Pump Rotor

4 -

Rotor Lock Washer

32

-

Pump Vane

5 -

Rotor Lock Bolt

33

Pump Vane Spring

6

—

Motor Lock Bushing

34

-

Pump Vane Spring

7 _

Roll Pin

Guide

8

_

Acorn Nut and Gasket

35

“

Retaining Spring

Ring Spacer

36

_

Oil Feed Guide Vane

9 —

10

Junction Box

37

-

Oil Feed Guide Vane

Spring

11 — Terminal Plate Assembly

38

_

Oil Pump Drive Segment

12 — Terminal Bolt Assembly

39

_

Screw, Soc Head

13 -

Terminal Bolt Assembly

1/4 - 28

X

5/8 in

14 -

Cover Plate

40

_

Screw, Soc Head no 10

15

Hex Head Screw

- 32

X

1/2 in

16 -

Cylinder Head Bolts

41

-

Cover Plate

17

—

Connecting Rod and

42

-

Cover Plate Cap Screw

Piston Assemblies

43

Oil Relief Piston

18 -

Compressor Crankcase

44

-

Crankshaft

19 -

Motor End Cover

45

_

Bearing Washer

20

-

Cylinder Head —

46

_

Piston Ring (Oil and

Center Bank

Compression)

21

-

Cylinder Head — Capacity

47

__ Piston, Piston Pin and

Control Side Bank

Retaining Ring

22

-

Internal Relief Valve

Package

23

_

Crankcase Oil Filter

48

-

Connecting Rod and

Screen

Cap Assembly

24

-

Oil Sight Glass Assembly

49

-

Valve Plate Package

25 -

Oil Sight Glass 0-Ring

50

-

Valve Plate

Gasket

51

-

Discharge Valve Stop

26

-

Oil Sight Glass Screw

52

-

Discharge Valve

27

Oil Sight Glass Lock

53

_

Valve Stop Support

Washer

54

_

Cap Screw, Valve Stop

28

_

Pipe Plug Gasket

(hex head)

55

— Suction Valve