Compressor running gear removal, Compressor running gear replacement – Carrier 06E User Manual

Page 14

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

REMOVE

1. Acorn nut and washer.

2. Back out locking pin and bushing.

REPLACE

1. Screw in locking pin bushing until it rests on

stator core.

2. Wrap a piece of tape around 3/8 in. drill bit,

2-1/16 in. from cutting edge.

3. Ream out bushing (3/8 in. drill) and drill into

stator core until tape is flush with top of

bushing. (Remove drill chips.) Back off locking

pin bushing 1/8 of a turn.

C A U T I O N '

B e f o r e

d r i l l i n g ,

b e

s u r e

s t a t o r

v e n t

h o l e s d o n o t l i n e u p w i t h l o c k i n g p i n h o l e . V e n t

h o l e s

a r e

d r i l l e d

h o r i z o n t a l l y

t h r u

s t a t o r ,

a n d

c a n b e s e e n f r o m e n d b e l l s i d e .

4. Tap locking pin into position. (Top of bushing

should be approximately 1/16 in. above top of

pin.)

5. Peen top of bushing over roll pin.

6. Replace washer and acorn nut.

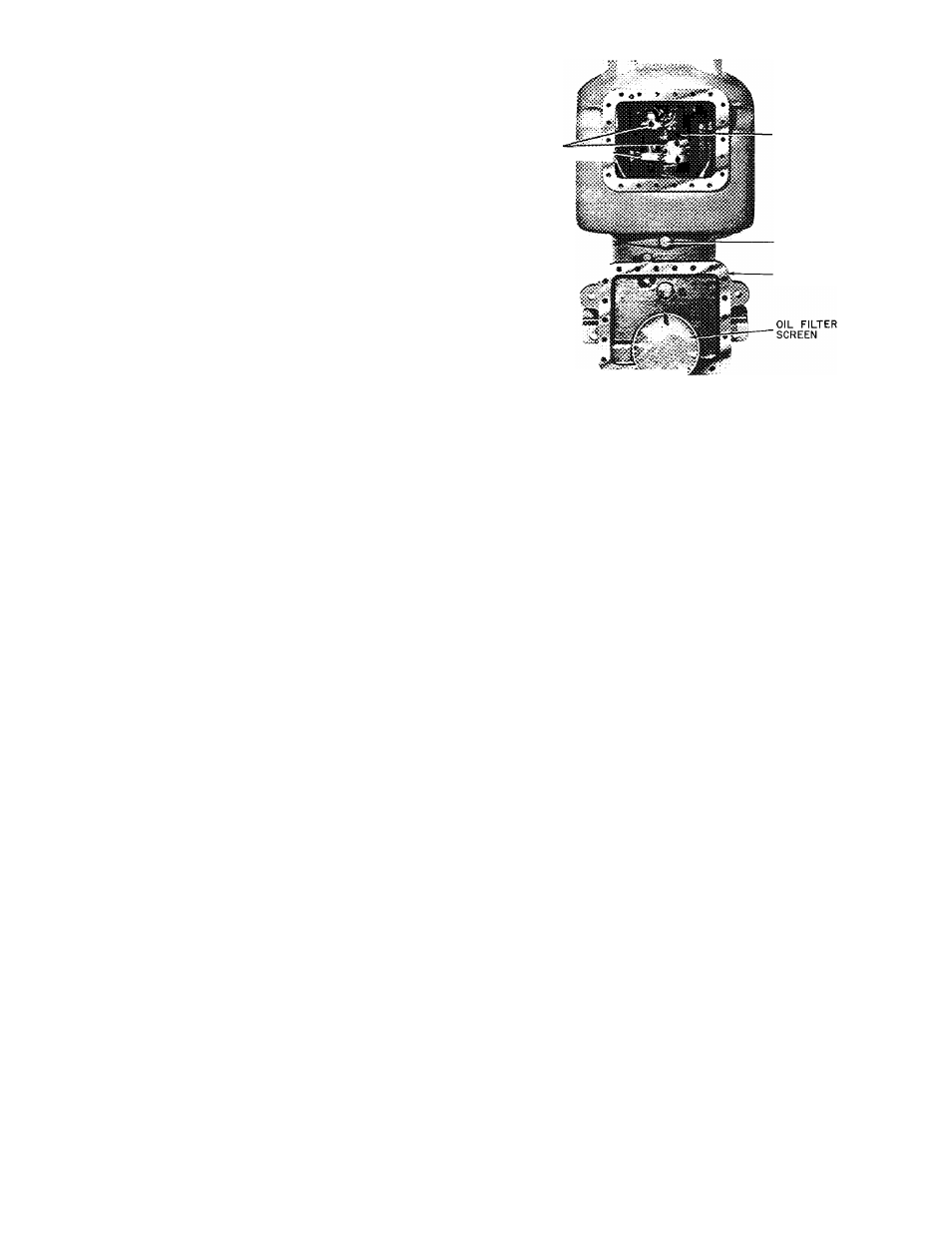

COMPRESSOR RUNNING GEAR REMOVAL

Connecting Rod and Piston Assembly

— Remove

cylinder heads, valve plate assemblies, crankcase

bottom cover plate, oil filter screen, and con

necting rod caps (Fig. 23.) (Label caps and rods so

they may be reinstalled in same place on crank

shaft.) Push connecting rod and piston assemblies

up thru cylinder deck. Disassemble connecting rods

from pistons by removing retaining rings and

piston pins. Remove oil and compression rings from

piston. (Keep each connecting rod and piston

assembly together for proper reassembly.) Check

all parts and crankpin journals for wear (refer to

Table 5 for wear limits).

Crankshaft

— Remove pump end bearing head and

rotor. If connecting rod and piston assemblies are

still in place, remove connecting rod caps and push

piston assembly up into cylinder for crankshaft

clearance. Pull crankshaft out thm pump end

opening. Inspect crankshaft journals for wear and

tolerances shown in Table 5. Check oil passages

and clean if clogged.

Pump End Main Bearing

is a machined part of the

oil pump and bearing head casting. Disassemble

bearing head. If bearing is scored or worn, replace

the complete bearing head.

Crankcase and Motor End Main Bearings

are not

field replaceable. If bearings are worn or damaged,

replace compressor.

CONNECTING

RODS a CAPS "'psTT;-

CRANKSHAFT

OIL DRAIN PLUG

(MAGNETIC)

BOTTOM COVER

PLATE

. 'Cv •

Fig. 23 — Removing Connecting Rod and

Piston Assemblies

COMPRESSOR RUNNING GEAR

REPLACEMENT

Crankshaft

— Be sure compressor end bearing

washer is in place on dowel pin. Install crankshaft

thru pump end, carefully guiding it thru main

bearings. Replace rotor.

Connecting Rod and Piston Assembly (Fig. 12) —

Attach connecting rods to pistons with piston pins,

and lock in place with retaining rings. Place

retaining rings with the gap on the side. They

should be tight enough so they cannot be rotated

by finger pressure.

RINGS

1. Check ring gap by inserting each ring separately

in cylinder approximately 3/8 in. from top.

Ring gap should be between .002 in. and

.007 in.

2. Install compression ring in top piston groove

with side marked “Top” toward piston head.

Install oil ring below compression ring with

notched end on bottom. Stagger ring gaps

around piston.

3. Measure side clearance between ring and piston

(Table 5). Check rings for free action.

Install connecting rod and piston assemblies

into cylinders. Place chamfered sides of connecting

rods against radius of the crankpins. Install

connecting rod caps to matching connecting rods

thru bottom cover plate. Be sure chamfered sides

of caps are against radius of crankpins. Caps are

locked in place with nylock cap screws. Use 8—10

Ib-ft torque to tighten cap screws.

Turn crankshaft to be sure there is no binding

between bearing surfaces and journals. Replace oil

screen, bottom cover plate, valve plates and

cylinder heads.

14