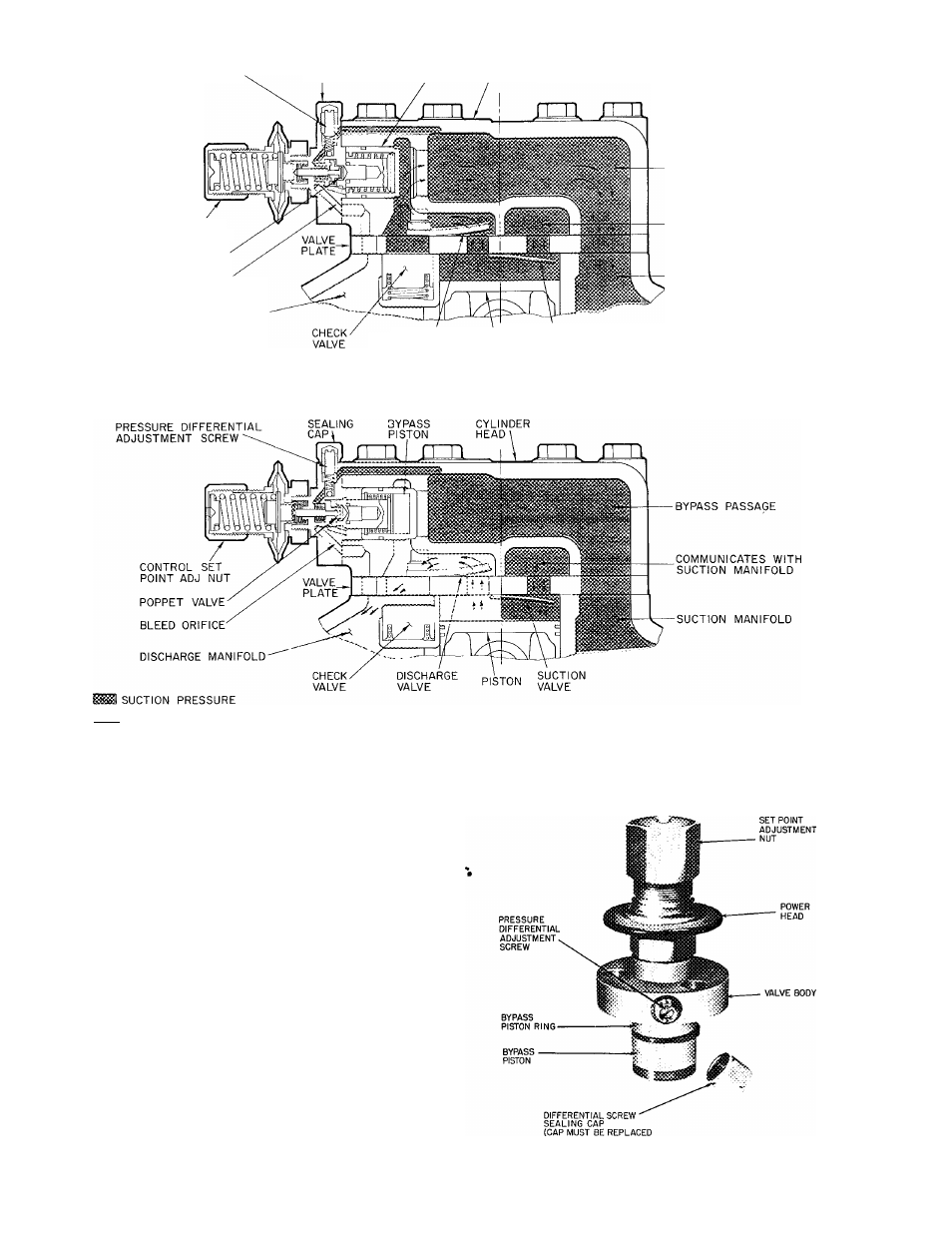

Fig. 7 — capacity control valve – Carrier 06E User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

PRESSURE

DIFFERENTIAL

ADJUSTMENT SCREW

SEALING

BYPASS

CYLINDER

CAP

PISTON

HEAD

CONTROL SET

POINT ADJ NUT

POPPET VALVE'

BLEED ORIFICE'

DISCHARGE MANIFOLD

SUCTION PRESSURE

nZH DISCHARGE PRESSURE

DISCHARGE

SUCTION

VALVE

PISTON VALVE

UNLOADED OPERATION

BYPASS PASSAGE

COMMUNICATES

WITH

SUCTION MANIFOLD

-SUCTION MANIFOLD

l~~~1 DISCHARGE PRESSURE

LOADED OPERATION

Fig. 6 — Capacity Control Valve Operation

TO REGULATE CONTROL SET POINT (Refer to

Fig. 7) —Turn adjustment nut clockwise to its

bottom stop. In this position, set point is 85 psig.

Control set point is then regulated to desired

pressure by turning adjustment nut counterclock

wise. Each full turn decreases set point by 7.5 psig.

Approximately 11 1/2 turns counterclockwise will

decrease control set point to 0 psig. Table 3 shows

the steps of control.

PRESSURE

DIFFERENTIAL

ADJUSTMENT

(Fig. 7) — Turn differential adjusting screw counter

clockwise to its back-stop position. In this posi

tion, differential is 6 psi. Pressure differential is set

by turning adjustment screw clockwise. Each full

turn increases differential by 1.5 psi. Approxi

mately 10 turns clockwise will increase pressure

differential to 22 psi.

CONTROL

TO PREVENT REFRIGERANT LEAKAGE)

Fig. 7 — Capacity Control Valve