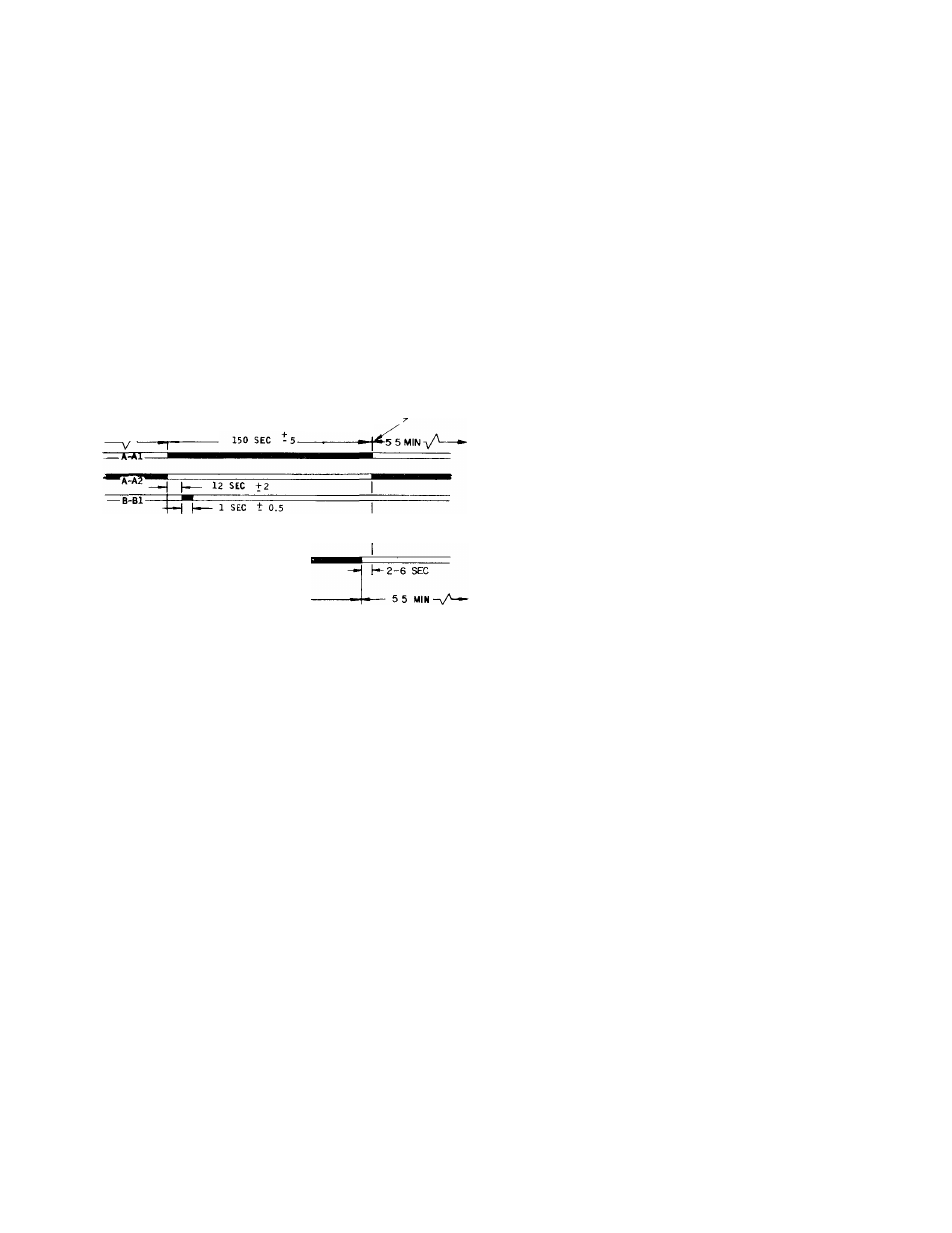

Fig. 5 — timer cycle protection devices, Capacity control system, Capacity control valve adjustments – Carrier 06E User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Timer Functions

(See Fig. 5 — Tinier Cycle)

1. Switch A (contacts A-Al and A-A2) provides

Time Guard® function. Start of compressor is

delayed approximately 5.5 minutes after shut

off. The minimum time between starts of

compressor is 8 minutes.

2.

Switch B (contacts B1 and B—B2) starts

compressor and de-energizes the crankcase

heater. These contacts also provide one-second

time delay for part-winding start.

3. Switch E (contacts E—El) provides approxi

mately 40-second bypass of oil-pressure switch

(OPS) at start-up. Compressor will shut off if

sufficient oil pressure does not build up.

4. Switch D (contacts D—Dl) bypasses the low-

pressure switch (EPS) for 2.5 minutes at start

up for winter start control.

(BLACK DENOTES CLOSED CONTACTS)

0 MIN OR

8 MIN

TIMER POSITION DURING

UNIT OPERATION-

»TT?*

-'E-El-

-xA-

40 SEC +5

2-6 SEC

---

150 SEC

Fig. 5 — Timer Cycle

PROTECTION DEVICES

High-Pressure Switch

— Check by throttling con

denser water or blocking air flow on air-cooled

units, allowing head pressure to rise gradually.

Check discharge pressure constantly throughout

procedure. Compressor should shut off within 10

psi of values shown in Table 1.

Low-Pressure Switch

— Check by slowly closing

suction shutoff valve or by completely closing

liquid line shutoff valve. A decrease of suction

pressure will follow. Compressor should shut off

within 4 psi of values shown in Table 1.

Oil Pressure Switch

(OPS) protects against damage

from loss of oil and failure of pressure buildup

during start-up. Switch time delay (approximately

35 seconds) is derived from being properly wired

to the ambient and voltage insensitive Time Guard

timer. If OPS locks out unit,

d e t e r m i n e a n d c o r r e c t

t h e c a u s e

(such as loss of compressor oil or flooded

compressor)

b e f o r e

r e s t a r t i n g

u n i t

Restart by

pushing the control circuit switch on unit control

box to “Stop” then to “Reset.” Failure to correct

the cause of the OPS lockout will constitute abuse.

E q u i p m e n t f a i l u r e d u e t o a b u s e i s n o t c o v e r e d b y

t h e W a r r a n t y .

Time Guard Control

protects compressor against

short cycling. See Start Compressor.

Crankcase Heater

prevents absorption of liquid

refrigerant by oil in crankcase during brief or

extended shutdown periods. Source of 115-volt

power is the auxiliary control power, independent

of the main unit power. This assures compressor

protection even when main unit power disconnect

switch is off.

N e v e r o p e n a n y s w i t c h o r d i s c o n n e c t t h a t w i l l

d e - e n e r g i z e

t h e

c r a n k c a s e

h e a t e r

u n l e s s

u n i t

i s

b e i n g

s e r v i c e d

o r

i s

t o

b e

s h u t

d o w n

f o r

a

p r o l o n g e d p e r i o d A f t e r a p r o l o n g e d s h u t d o w n o r a

s e r v i c e

j o b ,

e n e r g i z e

t h e

c r a n k c a s e

h e a t e r

f o r

2 4

h o u r s b e f o r e s t a r t i n g t h e c o m p r e s s o r .

Compressor Motor Protection

consists of 3 tem

perature sensors embedded in motor windings and

connected to a solid state module in unit control

box.

When an overtemperature condition causes

module to shut compressor off, push control circuit

STOP switch. Investigate cause of compressor shut

down and correct. After compressor cools, push

control circuit START-RESET switch. Compressor

will restart after Time Guard delay period.

SOLID STATE MODULE is checked by applying

unit control voltage to terminals T1 and T2 (see

label diagram), then checking for continuity across

terminals Ml and M2. If no continuity between Ml

and M2, check temperature sensor resistance using

a volt-ohmmeter. If all sensors check below 95

ohms (180 F) and there is no continuity between

module terminals Ml and M2, replace module.

C A U T I O N : D o n o t

u s e a

b a t t e r y p o w e r e d t e s t

l a m p

t o

c h e c k

s e n s o r s

E x c e s s i v e

c u r r e n t

c a n

c a u s e d a m a g e

If one sensor fails, it can be jumpered out of

the circuit with a 75 ohm, or higher, resistor (rated

at 2 watts or higher) across the proper sensor

terminal and common terminal. If a short to

ground in sensor circuit is indicated, replace

compressor motor.

CAPACITY CONTROL SYSTEM

Capacity Control Valve(s)

is controlled by suction

pressure and actuated by discharge pressure. Each

valve controls 2 cylinders. On start-up, controlled

cylinders do not load up until differential between

suction and discharge pressure is 10 psi (see Fig. 6).

D o

n o t

u s e

a u t o m a t i c

p u m p d o w n

c o n t r o l

o n

0 6 E , 0 7 E u n i t s e q u i p p e d w i t h u n l o a d e r v a l v e s . U s e

s i n g l e

p u m p o u t

o r

s o l e n o i d

d r o p

( m i n i m u m

p r o

t e c t i o n ) c o n t r o l

Capacity Control Valve Adjustments

CONTROL SET POINT (cylinder load point) is

adjustable from 0 psig to 85 psig. Pressure differ

ential between cylinder load-up point and cylinder

unload point is adjustable from 6 psi to 22 psi.