Cylinder heads (fig. 12), Terminal plate assembly – Carrier 06E User Manual

Page 11

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

2. Place the pump vanes, pump vane spring with

guides, and snap rings into the bearing head.

Compress the springs and force the snap rings

into their grooves. (Insert snap rings with flat

side against casting.)

3. Bolt bearing head to crankcase (use 55 to 65

Ib-ft torque). Bolt drive segment to crankshaft.

4.

Insert the oil feed guide vane with large

diameter inward. Place oil feed guide vane

spring over small diameter of guide vane.

5. Install pump cover plate.

CYLINDER HEADS (Fig. 12)

Disassemble cylinder heads by removing cap

screws, and prying up on side lifting tabs to break

heads loose from valve plates. Do not hit cylinder

heads to break loose.

Check heads for warping, cracks and damage to

gasket surfaces. When replacing cylinder head,

torque cap screws 90 to 100 Ib-ft (prevents high to

low side leak in center portion of cylinder head

gasket).

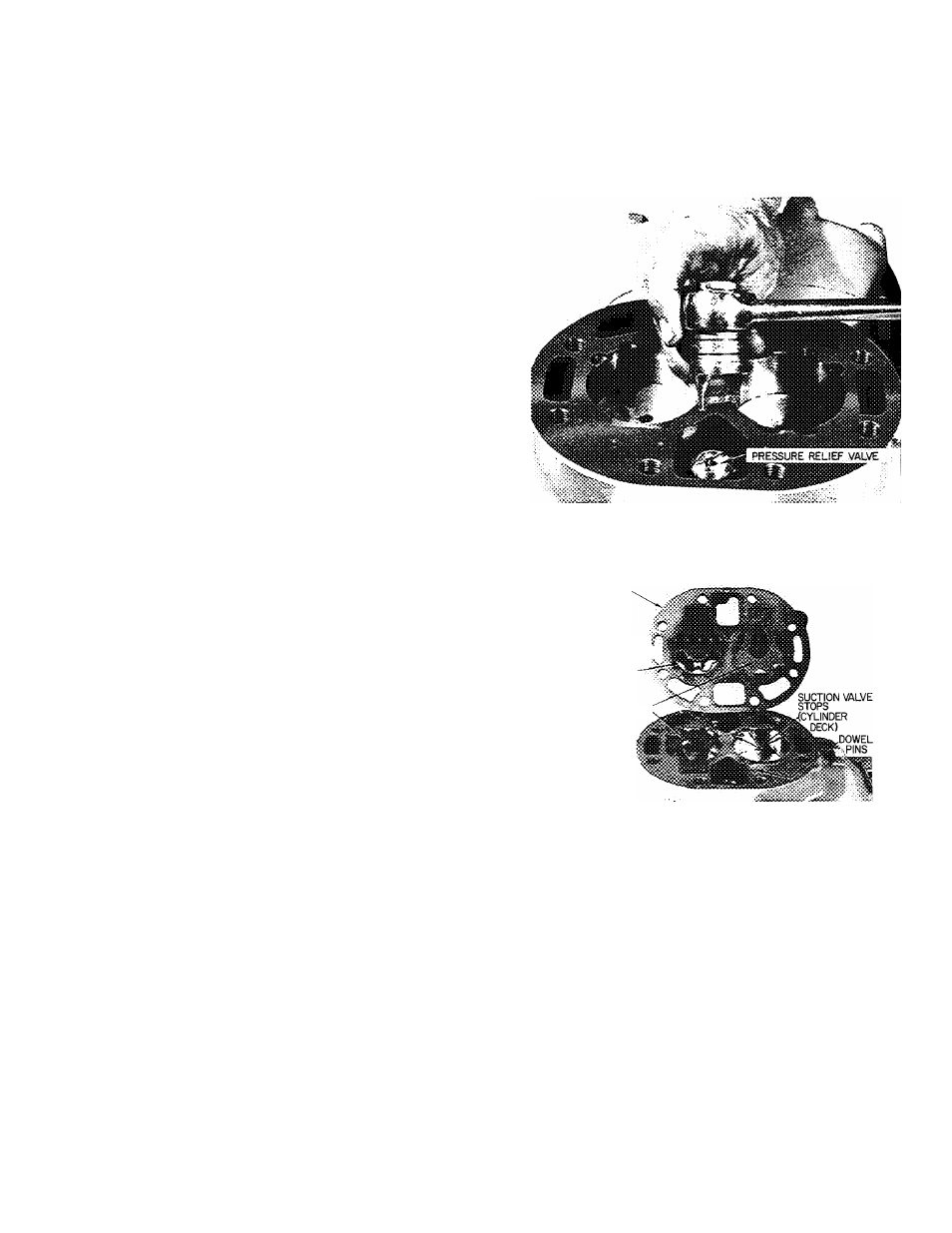

Pressure Relief Valve

— This safety device is

located in center cylinder bank (6-cylinder com

pressors, Fig. 15) or under discharge service valve

(4-cylinder compressors). The valve relieves refrig

erant pressure from high to low side at 400 psi

pressure differential. Check valve for evidence of

leaking. Change if defective or if valve has ever

opened due to excessive pressure. Use a standard

socket-type screwdriver to remove and replace

valve.

SUCTION AND DISCHARGE VALVE

PLATE ASSEMBLY (Fig. 12)

Test

for leaking discharge valves by pumping

compressor down and obseiving suction and

discharge pressure equalization. If a discharge valve

is leaking, their pressures will equalize rapidly.

Maximum allowable discharge pressure drop is 3

psi per minute.

If there is an indicated loss of capacity and

discharge valves check properly, remove suction

and discharge valve plate assembly and inspect

suction valves.

Disassemble

— Remove cylinder head.

1. Remove discharge valve assembly: cap screws,

valve stops, valve stop supports and valves.

2. Pry up on side lifting tab to remove valve plate

and expose suction valves (Fig. 16). Remove

suction valves from dowel pins.

Inspect valves and valve seats for wear and

damage (see Wear Limits, Table 5). Replace valves

if cracked or worn. If valve seats are worn, replace

complete valve plate assembly.

Reassemble

— Do not interchange valves. Install

suction valves on dowel pins. Place valve plate on

cylinder deck, and reinstall discharge valve

assembly. Retorque discharge valve stop cap screws

to 16 Ib-ft. Replace cylinder head. (Be sure tab on

cylinder head gasket is lined up with tabs on

cylinder head and valve plate.)

Fig. 15 — Pressure Relief Valve Removal

VALVE PLATE

SUCTION VALVE ?

SEATS

(VALVE PLATE)

SUCTION VALVES <

Fig. 16 — Valve Plate Removed

TERMINAL PLATE ASSEMBLY

Removal

— Disassemble junction box from termi

nal plate, and remove cap screws holding terminal

plate to compressor. Mark all motor leads so they

can be reassembled correctly to terminal plate.

Loosen alien head screws holding motor leads to

terminal plate (Fig. 17). Remove terminal plate.

Power Lead Terminal Stud

— Disassemble only if

leaking refrigerant or if resistance to ground is low.

If there is a short to ground, replace complete

terminal plate assembly.

DISASSEMBLE (Fig. 18)

1. Unscrew terminal, terminal locknut, and termi

nal bolt assembly hex nut.

11