Electrical requirements, Accessories – Carrier 06E User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

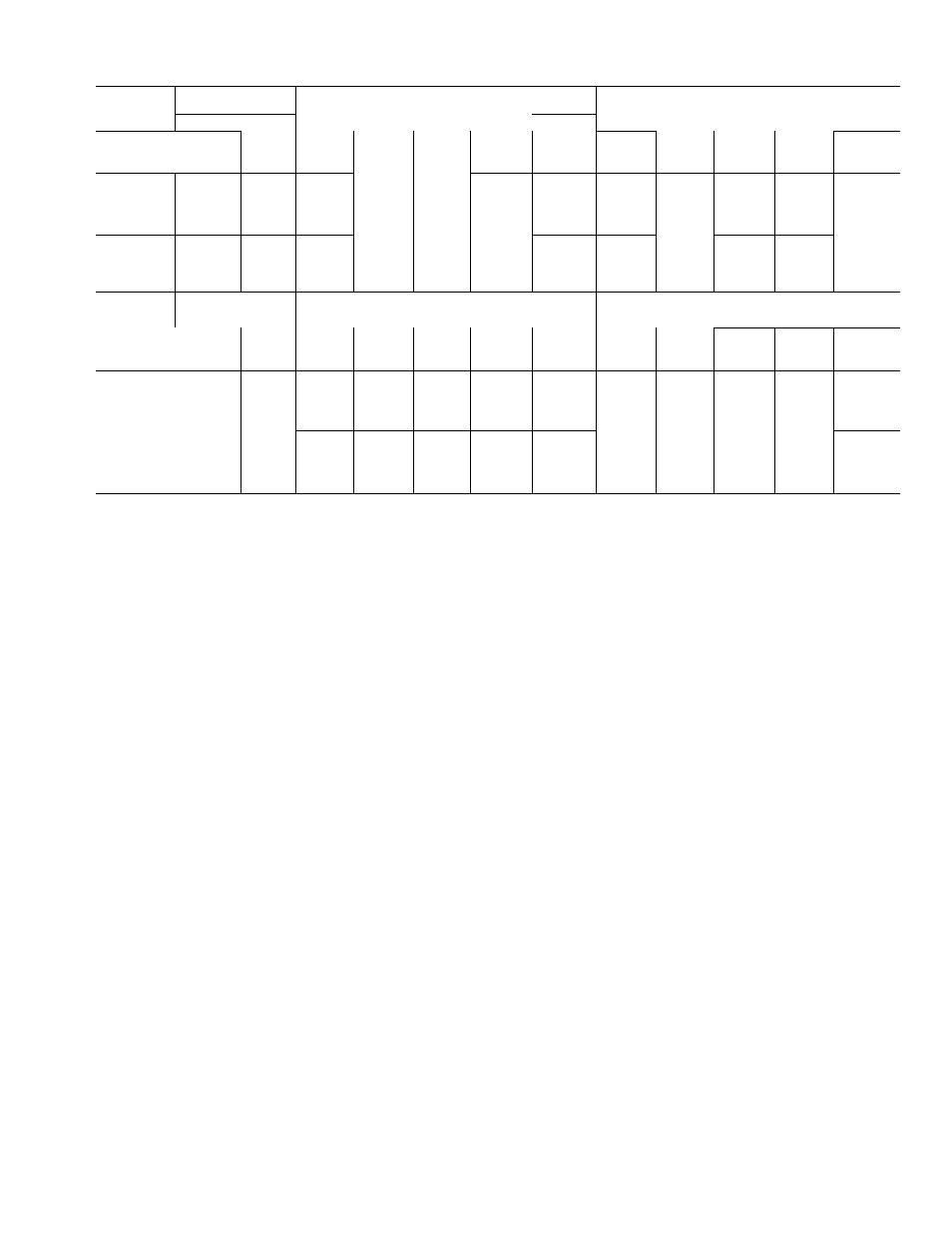

Table 2 — Electrical Data (60-Hertz, 3-Phase)

(Circuit Breakers Selected for Units Using R-22)

VOLTS

Nomina 1

200

230

Supply Range

180-229

207-264

MÀX

MAX

UNIT

KW

RLA

LRA

MTA

MWA

FUSE

RLA

LRA

MTA

MWA

FUSE

AMPS

AMPS

V022

24.8

g2

345

114

102

175

75

300

104

94

150

Compr

W027

33.6

103

471

144

129

225

92

410

128

115

200

06 E

W033

37.6

1 14

506

160

143

250

103

440

144

129

225

W044

55.1

164

690

230

206

350

150

600

210

188

300

A022

22.6

72

283

100

90

150

63

r 246

88

79

125

Cond

B027

31.4

96

471

134

120

200

85

410

118

106

175

07 E

B033

34.0

107

471

150

134

225

96

410

134

120

200

D044

50.4

159

690

222

198

350

140

600

196

175

300

VOLTS

Nominal

460

575 (See Note 5)

Supply Range

414-528

518-660

MAX

MAX

UNIT

KW

RLA

LRA

MTA

MWA

FUSE

RLA

LRA

MTA

MWA

FUSE

AMPS

AMPS

V022

24.8

36

150

50

45

80

29

120

40

37

60

Compr

W027

33.6

45

205

63

56

100

36

164

50

45

80

06 E

W033

37.6

51

220

71

64

no

42

176

58

53

90

W044

55.1

76

300

106

95

150

60

240

84

75

125

A022

22.6

32

123

45

40

70

27

98

37

34

60

Cond

B027

31.4

43

205

60

54

90

33

164

45

42

70

07 E

B033

34.0

48

205

66

60

100

39

164

54

48

80

D044

50.4

70

300

98

88

150

60

240

84

75

125

KW

— Maximum Power Input

LRA

— Locked Rotor Amps

MTA

— Must Trip Amps

MWA

— Minimum Wire Amps Complies with NEC Section

430-22

RLA

— Rated Load Amps

Supply Range — Units are suitable for use on electrical systems

where voltage supplied to the unit terminals is

not below or above the listed range limits

NOTES:

1 Control voltage is 115 v for all units

(Continued from page 1.)

suction line so compressor suction valve may be

moved aside for access to suction strainer.

A solenoid valve is necessary for single pump

out control used on 06E and 07E units. Install the

valve (field supplied) in the liquid line, just before

the expansion valve. A filter-drier of adequate size

should be installed in liquid line between con

denser and solenoid valve.

Pressure relief valve located on side of con

denser will open to relieve excessive pressure,

allowing refrigerant to escape. Most local codes

require piping from valve to outdoors.

Refer to Carrier System Design Manual for

standard piping techniques.

ELECTRICAL REQUIREMENTS

Eield wiring must comply with local and

national codes. See Table 2.

Install a branch circuit fused disconnect of

adequate size to handle starting current. The

disconnect must be within sight of the unit and

readily accessible, in compliance with National

Electrical Code (NEC), Section 440—14.

Line power is brought into control center thru

indicated opening. Connect line power supply to

2 Part-winding start all 200-, 230-volt 06E and 07E units; 460-,

575-volt 06EW044 and 07ED044 units

Across-the-line

start:

all

460-,

575-volt

units

except

06EW044

and 07ED044.

3. Factory wiring is in compliance with National Electrical Code

(NEC)

Field

wiring

must

comply

with

NEC

and

applicable

local

codes

Maximum

incoming

wire

size

to

control

center

terminal block is 250 MCM

4 The 06E compressor unit electrical data shown in the table

does not apply to 06E compressors used as an integral part of

other

Carrier

equipment

Refer

to

the electrical data

for the

particular application

-> 5 Units for use on 575 volts are available on special order

terminal block TB1; connect power leads to

terminals LI, L2 and L3. Connect control circuit

power supply (115 volts) to terminals 1 and 15 on

terminal block TB2. Refer to Eig. 4.

Wiring connections for field-supplied equip

ment are shown on diagram attached to unit (or in

wiring diagram booklet).

Discharge line limit thermostat supplied with

06EV,W compressor units is installed on discharge

line as close to compressor as possible.

1. Place mounting plate on discharge line and

solder in place.

Easten the thermostat to plate with screws

supplied.

Cover switch with insulation and secure insula

tion at each end with straps.

Connect thermostat in series with Ml and M2

overloads, between terminals 2 and 4 on termi

nal block TB2.

ACCESSORIES

2

.

3.

4.

PACKAGE NUMBER

07EA900021

07EA900061

DESCRIPTION

Control

Circuit

Transformer

Gage Panel

1276