Capacity control valve operation (fig. 6), Condenser maintenance (07e units) – Carrier 06E User Manual

Page 7

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Capacity Control Valve Operation (Fig. 6)

LOADED - When suction pressure is above con

trol point, the poppet valve closes. Discharge gas

bleeds into valve chamber, the pressure closes

bypass piston and cylinder bank loads up. Dis

charge gas pressure forces check valve open, per

mitting gas to enter discharge manifold.

UNLOADED — When suction pressure drops below

valve control point, the poppet valve opens. Dis

charge gas bleeds from behind bypass piston to

suction manifold. Bypass piston opens, discharge

gas is recirculated back to suction manifold and

cylinder bank is unloaded. Reduction in discharge

pressure causes check valve to close, isolating

cylinder bank from discharge manifold.

Table 3 — Steps of Control

COMPRESSOR

STEPS

06 E

1

2

3

CONDENSING

No.

%

No.

%

No.

%

UNIT 07E

Cyl

Cap.

Cyl

Cap.

Cyl

Cop.

06EV022

07EA022

4

100

2

50

-

-

06EW027

07EB027

6

100

4

67

2

33

06EW033

07EB033

6

100

4

67

2

33

06EW044

07 ED 044

6

100

4

67

2

33

NOTE:

Capacity

control

valve

(Fig

7)

factory

settings

for

4-cylinder

units are: 69 psig control set point (cylinder load point), 10 psig

differential

(59

psig

cylinder

unload

point)

Settings

for

6-

cylinder units are: left cylinder bank control set point is 70 psig,

differential is 10 psig; right cylinder bank control set point is 68

psig, differential is 10 psig

Service Replacement Compressors

are not equip

ped with capacity control valves. Side bank

cylinder head(s) is plugged with spring loaded

piston plug assembly(ies). Compressor will run

fully loaded with piston plug(s) in place.

Transfer original capacity control valve(s) to

corresponding

cylinder

bank(s)

in

replacement

compressor

(ensures proper valves are used with

correct setting). Install piston plug assembly(ies)

into original compressor for sealing purposes.

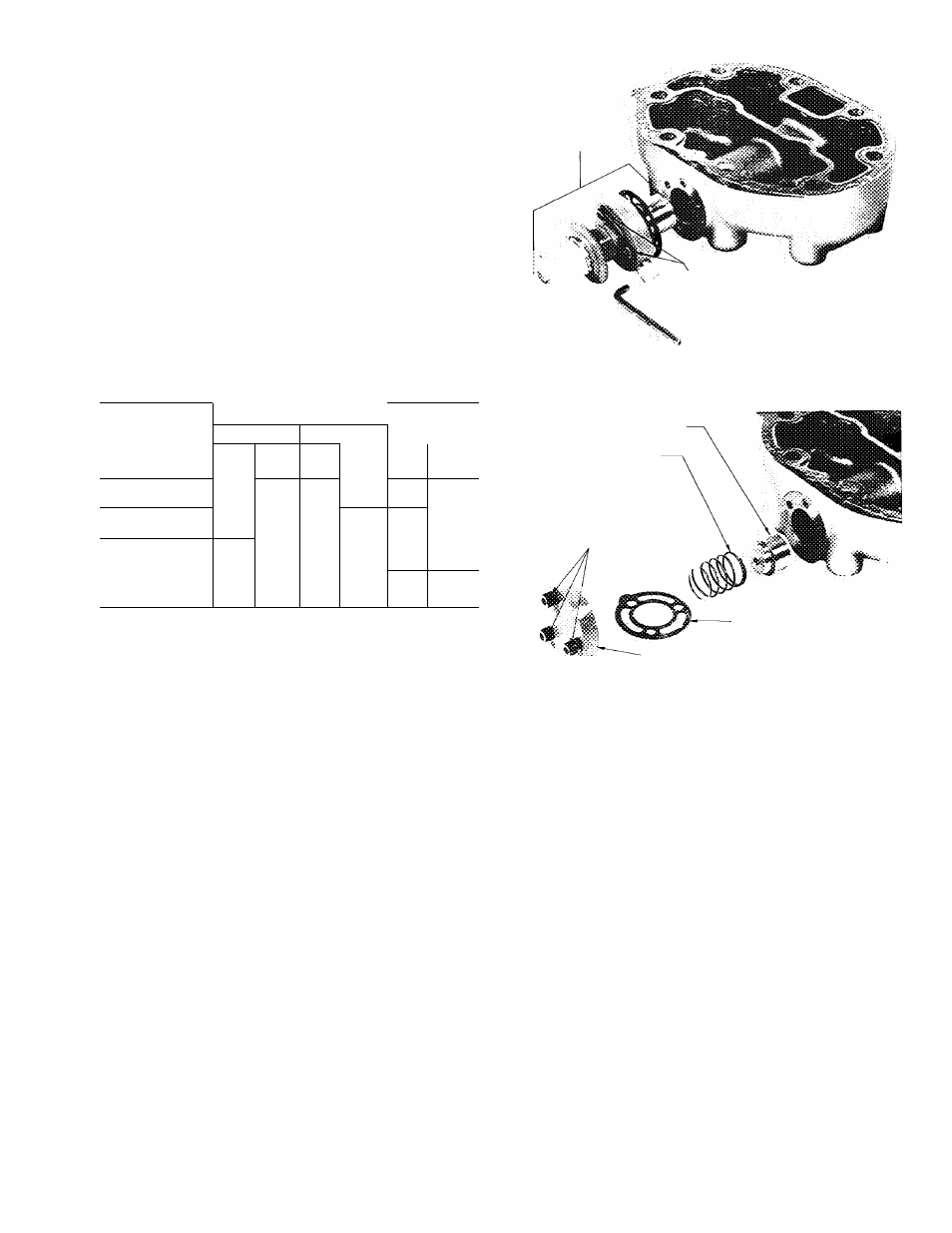

Three alien head cap screws hold capacity

control valve in place (Fig. 8). Remove screws

using a “cut down” 3/16-in. alien wrench, and pull

valve from cylinder head.

Remove same number of piston plugs from

replacement compressor as number of unloaders

supplied with original compressor. Three alien head

cap screws hold piston plug assembly in place.

Remove flange cover, gasket, spring, and piston

plug (Fig. 9). A tapped hole is provided in piston

to allow it to be pulled out. Hole has same thread

diameter as cap screws removed above.

CAPACITY

CONTROL

VALVE

CAP SCREWS

(NONINTERCHANGEABLE

WITH FLANGE COVER

CAP SCREWS)

Fig. 8 — Removal of Capacity Control Valve

BYPASS PISTON PLUG

SPRING

CAP SCREWS

(NONINTERCHANGEABLE

WITH CONTROL VALVE

CAP SCREWS)

GASKET

-FLANGE COVER

Fig. 9 - Removal of Bypass Piston Plug

CONDENSER MAINTENANCE (07E Units)

To inspect and clean condenser, drain water

and remove condenser heads. To drain condenser,

shut off water supply and disconnect inlet and

outlet piping. Remove drain plugs and vent plug.

With condenser heads removed, inspect tubes

for refrigerant leaks. (Refer to Carrier Standard

Service Techniques Manual, Chapter 1, Section

1-6, Leak Testing, for instructions.)

Clean condenser tubes with nylon brush (avail

able from Carrier Service Department). Flush water

thru tubes while cleaning. If hard scale has formed,

clean tubes chemically. Do not use brushes that

will scrape or scratch tubes.

For chemical cleaning solution, use inhibited

hydrochloric acid solution (Oakite 32). Handle

acid cautiously. Clean condenser by gravity or

forced circulation (Fig. 10 and 11). For average

scale deposits allow acid solution to remain in

condenser overnight; for heavy deposits, allow 24

hours. Drain condenser and flush with clean water.

NOTE: Protect condenser from freezing when

ambient is below 32 F by draining water from

system or adding antifreeze to water.