Table 5 — wear limits — 06e compressor, Motor removal, Fig. 18 — power lead terminal stud assembly – Carrier 06E User Manual

Page 12

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

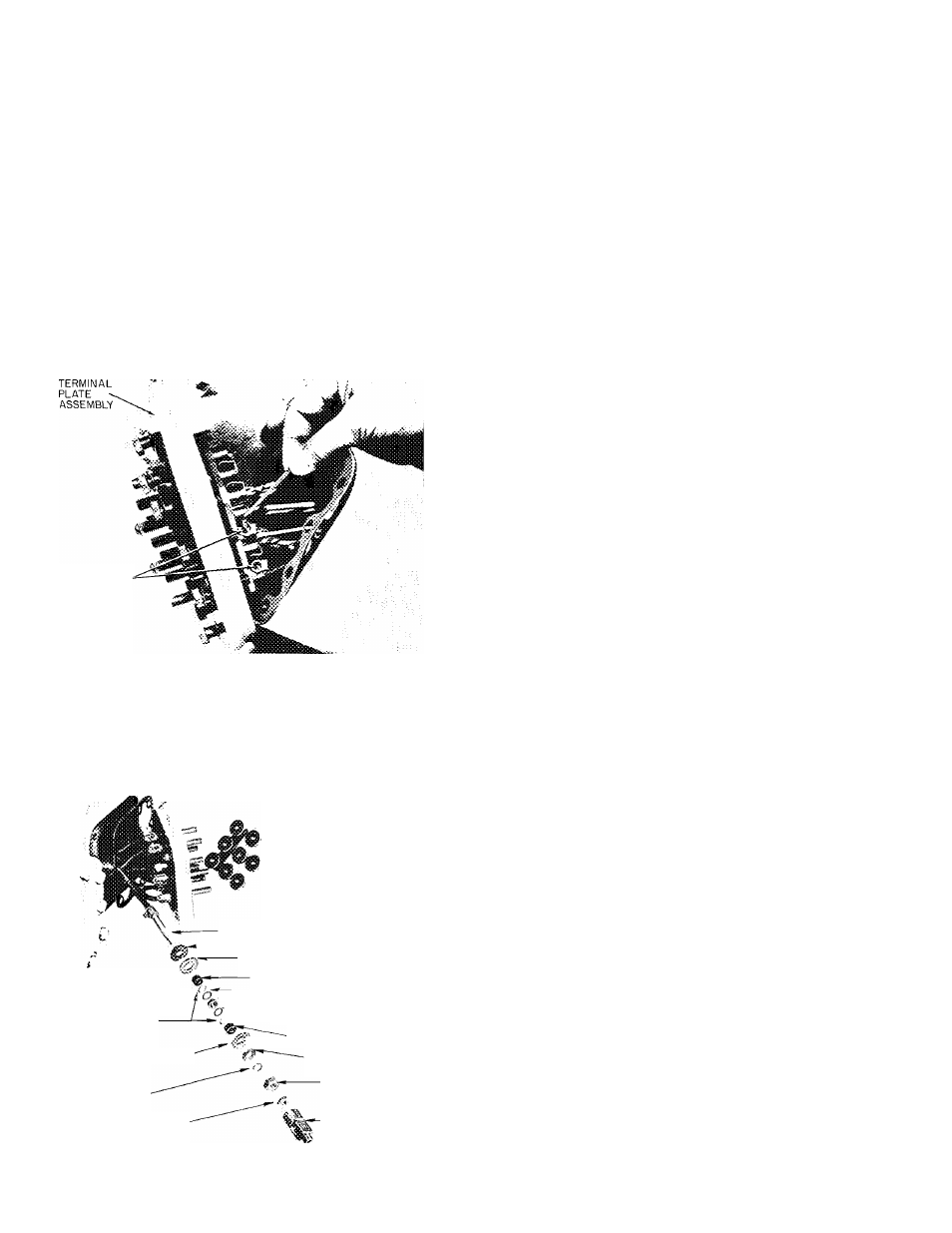

2. Push terminal bolt thru terminal plate and

remove insulating washers.

Inspect for grounds, insulation breakdown, and

sufficient life remaining in terminal seal bush

ings. It is recommended that disassembled

terminal stud assemblies be replaced with new

parts.

REASSEMBLE

1. Refer to Fig. 18 for position of terminal

assembly parts (washers are color coded).

2. Tighten terminal bolt assembly hex nut only

enough to stop escape of refrigerant gas (max

imum recommended torque is 4 Ib-ft). Do not

tighten nuts so terminal insulation washers are

flush with mounting plate.

Table 5 — Wear Limits — 06E Compressor

ALLEN

HEAD

SCREWS (T)

COMPRESSOR PART

MOTOR END

Main Bearing Diameter

Journal Diameter

PUMP END

Main Bearing Diameter

Journal Diameter

CONNECTING ROD

Bearing Diameter

(After Assembly)

Crankpin Diameter

THRUST WASHER

(Thickness)

CYLINDERS

Bore

Piston Diameter

Wrist Pin Diameter

Con. Rod Wrist Pin ID

Piston Ring End Gap

Piston Ring Side

C learance

FACTORY

TOL. (in.)

Max

VALVE

THICKNESS

D ischarge

END CLEARANCE

Suctic

1 .8760

6260

1 7515

2 6885

8755

007

003

0315

0255

0225

031

1 8725

6233

7483

155

2 6817

8748

002

001^

0305

0245*

0215

MAXIMUM

ALLOWABLE

WEAR* (in.)

001

"

001

"

002

*

002

002

001

001

015

002

002

002

010

""Maximum

allowable

wear

above

maximum

or

below

minimum

factory

tolerances

shown

For

example

difference

between

main

bearing

diameter

and

journal

diameter

is

0035

in

(1 8760 — 1 8725) per factory tolerances Maximum allowable

difference is 0045 in (0035+ 001)

Fig. 17 — Removing Terminal Plate Assembly

■r--7.7X

TERMINAL

INSULATION

WASHERS(GRAY)

TERMINAL

INSULATION

WASHER

LOCK WASHER

(SPRING)

TERMINAL LOCKNUT

TERMINAL BOLT ASSEMBLY

TERMINAL INSULATION WASHER

INSULATION WASHER

■TERMINAL INSULATION BUSHING

-----TERMINAL SEAL BUSHING

TERMINAL SEAL WASHERS

(RED)

TERMINAL INSULATION

BUSHING

PLATE WASHER

HEX NUT

■TERMINAL

Fig. 18 — Power Lead Terminal Stud Assembly

MOTOR REMOVAL

Motor End Bell

— Remove motor end bell care

fully to prevent damage to the stator. Use three

7/16 — 1 4 x 5 in. studs for guides and support. In

spect suction strainer in end bell. Clean it with sol

vent or replace if broken or corroded.

Rotor

— Bend rotor lock washer tab backward and

remove rotor lock bolt. If crankshaft turns, pre

venting lock bolt from being loosened, remove a

cylinder head and valve plate and place a rubber

plug (06R suction plug) on top of one piston (Fig.

19). Replace valve plate assembly and cylinder

head (only two bolts required to hold cylinder

head in place). Proceed to remove rotor lock bolt,

lock washer and plate washer.

Use a jackscrew to remove rotor (Fig. 19).

Insert a brass plug into rotor hole to protect end of

crankshaft from jackscrew. Support rotor while it

is being removed to prevent stator damage. Re

move ring spacer between rotor and crankshaft.

Clean rotor thoroughly with solvent. If stator is

to be replaced, a matching rotor must be used.

12