Initial start-up – Carrier 06E User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

REFRIGERANT

CHARGING

Evacuate, Dehydrate and Leak Test

the entire

refrigerant system by methods described in Carrier

Standard Service Techniques Manual, Chapter 1,

Sections 1-6 and 1-7. Use sight glass method to

charge system. See Section 1-8 of Service Tech

niques Manual for details.

CHARGE THE SYSTEM to a clear sight glass while

holding saturated condensing pressure constant at

125 F (air-cooled systems) or 105 F (water-cooled

systems) Add additional refrigerant to fill con

denser subcooler coils.

07E Condensing Units - After clear sight glass is

obtained, add charge until liquid refrigerant

reaches condenser liquid level test cock.

06E Compressor Units — See condenser data for

additional charge required to fill subcooler.

All Units — Stamp type of refrigerant and amount

of charge on unit informative plate

INITIAL START-UP

Crankcase heater should be energized a mini

mum of 24 hours before starting unit.

Check to see that oil level is approximately 1/3

up on the compressor sight glass.

Open water supply valve and allow water to

reach condenser. (Turn condenser fan on when the

compressor unit is applied with air-cooled con

denser.)

Backseat the compressor suction and discharge

shutoff valves, open liquid line valve at receiver.

Start evaporator fan or chilled water pump.

Start Compressor

— Push the control circuit

START-STOP-RESET switch to “Start.” The timer

motor starts immediately. Depending on the posi

tion of the timer, the compressor start is delayed

for 12 seconds to approximately 8 minutes. Check

oil pressure after compressor has run a few

minutes, the pressure should be 12—18 psi above

the suction pressure After about 20 minutes of

operation, stop the compressor. Allow it to be idle

for about 5 minutes, then observe the oil level in

the sight glass. If the oil level is below the bottom

of the sight glass, refer to the Carrier Standard

Service Techniques Manual, Chapter 1, Section

1-11, for adding oil. The proper oil level for the

06E compressor is approximately 1/3 up on sight

glass.

là

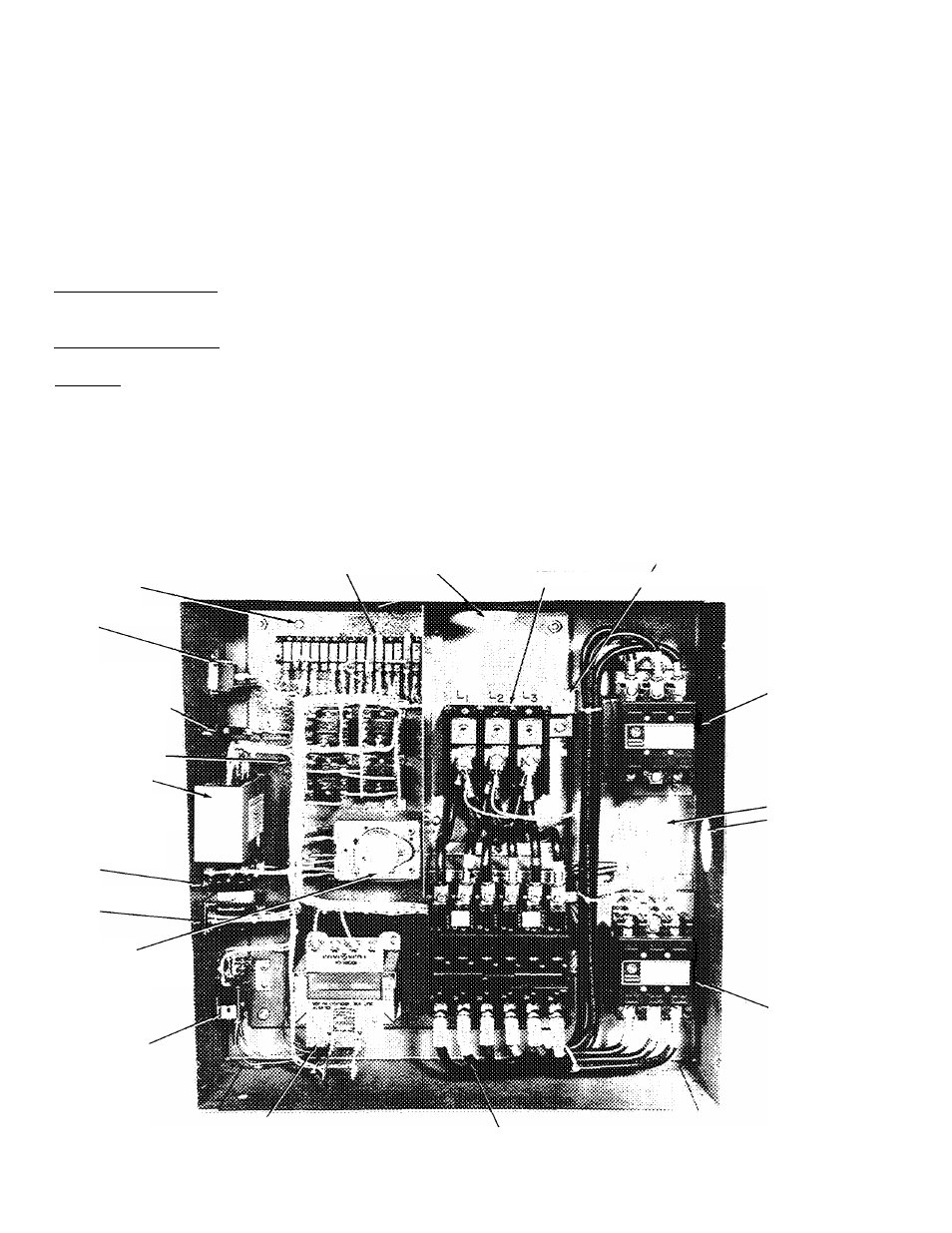

CONTROL POWER TERMINAL STRIP (TBg)

GROUND SCREW

START-STOP-RESET

SWITCH

MAIN POWER

INLET,

MAIN POWER

TERMINAL

BLOCK (TB|)

EQUIPMENT GROUND

'

connection

CONTROL CIRCUIT

FUSE(S)

(2 ON 50-Hz UNITS)

CONTROL RELAYS

SENSOR MODULE

(SOLID STATE

COMPRESSOR MOTOR

PROTECTION)

COMPRESSOR

CONTACTOR

OUTLET FOR

WIRING TO

COMPRESSOR

06E

07E

HIGH PRESSURE

SWITCH

LOW PRESSURE

SWITCH

TIMER MOTOR

(4-FUNCTION TIMER)

OIL PRESSURE

SAFETY SWITCH

COMPRESSOR

CONTACTOR

(PART-WIND)

ACCESSORY TRANSFORMER

(60-Hz UNITS ONLY)

MAIN POWER

CIRCUIT BREAKER

Fig. 4 — Control Center — 06E and 07E

1276

4