Top Flite TOPA0101 User Manual

Page 7

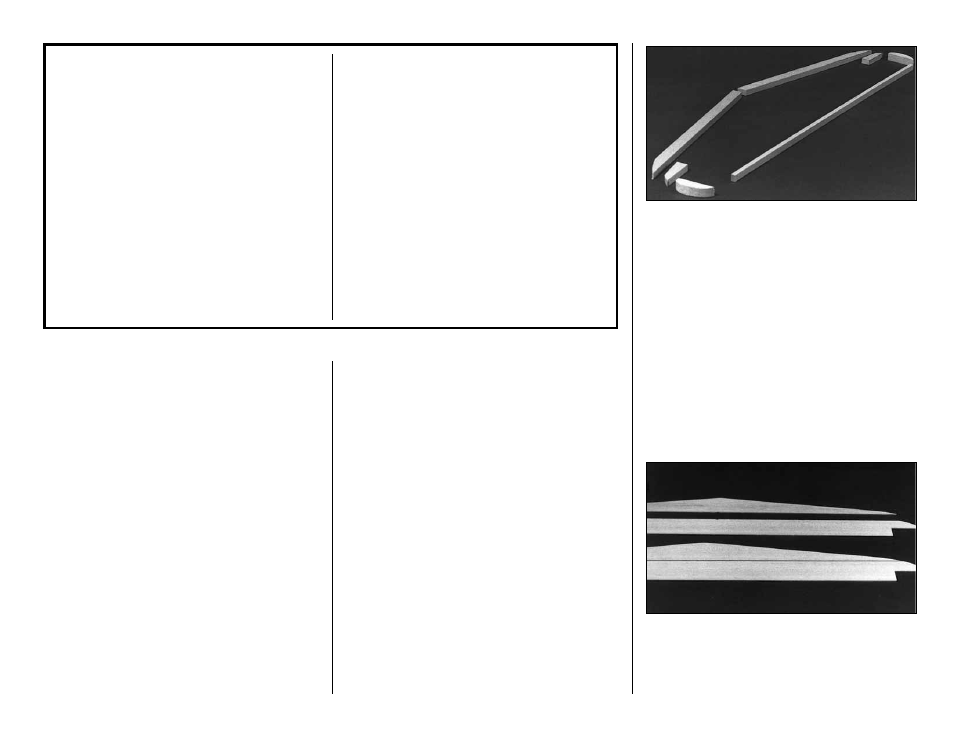

Sanders

are made from lightweight extruded

aluminum and can be found at most hobby shops.

They are available in three sizes – 5-1/2"

(GPMR6169) – 11" (GPMR6170) for most general

purpose sanding and 22" (GPMR6172) for long

surfaces such as wing leading edges. We

recommend using the 2" wide self-adhesive

sandpaper sold in 12' rolls by Great Planes.

Standard sandpaper can be attached by gluing it

to the sander with brush-on rubber cement. Apply

the rubber cement to both the bottom of the

sander and the back of the sandpaper. When both

surfaces are dry to the touch, press the sandpaper

firmly onto the sander. Spray adhesive can be

used for this purpose but it’s much harder to

remove the sandpaper when you need to replace

it. Use a knife blade for cutting sandpaper, not

your good scissors!

GET READY TO BUILD

❏

1. Unroll the plan sheets. Reroll the plan sheets

inside out to make them lie flat.

❏

2. Remove all parts from the box. As you do,

determine the name of each part by comparing it

with the plan. Using a felt-tip pen, write the part

name or size on each piece to avoid confusion later.

Use the die-cut patterns shown on pages 4 and 5 to

identify the die-cut parts and mark them before

punching out. Save all scraps. If any of the die-cut

parts are difficult to punch out, do not force them!

Instead, first cut around the parts with a hobby knife.

After punching out the die-cut parts, use your bar

sander or sanding block to lightly sand the edges to

remove any die-cutting irregularities.

❏

3. As you identify and mark the parts, separate

them into groups, such as fuse (fuselage), wing, fin

and stab (stabilizer), and hardware.

BUILD THE STAB

❏

1. Arrange the

stab

portion of the plan on a

flat building board (you may wish to cut out the

stab section). Cover the area over the stab with

waxed paper.

7

OTHER ITEMS REQUIRED

❏

Four-Channel Radio with 4 servos (additional

channels and servos required if retracts and/or

flaps are used).

❏

Top Flite Power Point

®

Propellers (see engine

instructions for recommended sizes)

❏

Prop Safety Nut (Great Planes has sizes and

styles that work nicely)

❏

12 oz Fuel Tank (DUBQ0212)

❏

5/32" Wheel Collars - 4 (GPMQ4306)

❏

3/32" Wheel Collars - 2 (GPMQ4302)

❏

Top Flite MonoKote Covering Material (Insignia

Blue and Yellow)

❏

Fuelproof Paint* for Cowl, Canopy and Oil

Coolers (Top Flite LustreKote

™

recommended)

❏

Latex Foam Rubber Padding, 1/4" thick

(HCAQ1000)

❏

Silicone Fuel Tubing (GPMQ4131)

❏

Plastic Pilot: Williams Bros. Standard, 2" Scale

#17600 (WBRQ1050)

❏

Main Gear Retracts (optional)...Robart #615

(ROBQ1815) Century Jet 33325 - complete

kit (CJMQ3055)

❏

Air Control Kit (optional retracts)...Robart

#188VRX (ROBQ2307) (Not required with CJ

33325)

❏

Oleo Robo Struts (optional)...Robart #650

(ROBQ1700) (Not required with CJ 33325)

❏

Hinge Points (optional flaps)...Robart #308

(ROBQ2508)

❏

3-1/4" Main Wheels...Robart #134 (ROBQ1534)

❏

1-1/4 Tail Wheel (GPMQ4242)

❏

.60 to .80 2-stroke, .90 to 1.20 4-stroke

NOTE:

Top Flite “LustreKote Paint” matches

MonoKote covering and is available in aerosol cans.

❏

2. Cut the balsa 3/8" x 5/8" x 24"

LE stock

to fit

nicely at the center joint. Save excess material for

the fin LE. Trim the tip of the LE to the approximate

shape on the plan but leave about 1/16" excess for

final shaping later.

❏

3. Cut the balsa 1/4" x 3/8" x 30"

TE stock

to

the correct length. Extra material is kept for the Fin.

❏

4. Cut the two

elevator tip blocks

from the 1/2"

x 1/2" x 4" balsa stick provided. Shape the tips to

match the plan shape.

❏

5. Make the

stab tips

from excess 3/8" x 5/8" LE

stock. Set the previously made parts aside for now.

❏

6. Make a top and bottom stab skin by placing

the 1/16" die-cut balsa pieces,

stab front

and

stab

back

, together over waxed paper and glue them

together with thin CA. Block sand the skins lightly

with 220-grit sandpaper.