Top Flite TOPA0101 User Manual

Page 22

❏

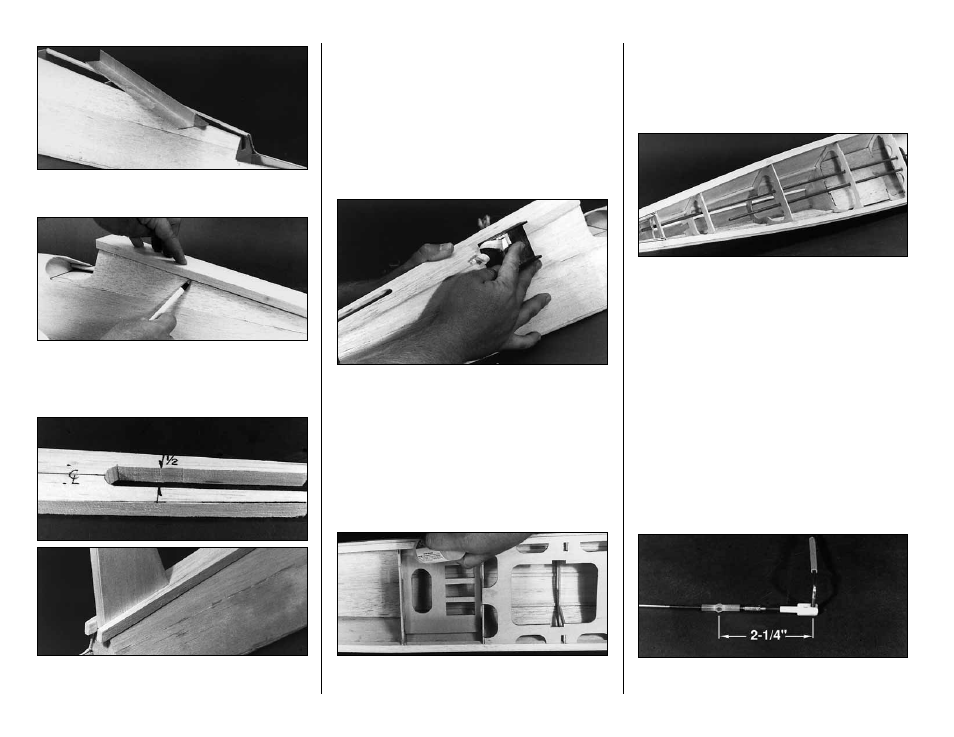

28. Use a sanding block to sand the top of the aft

deck sheeting down to the height of the former tops.

❏

29. Place the 1/2" x 2" x 17-7/8"

top deck block

on top of the fuse. Trace the shape of the fuse

onto the bottom of the block. Roughly cut the block

to shape.

❏

30. Mark a 1/2" wide slot on the top deck block

that will allow the fin to protrude through. Notice

that the fin LE sweeps back. Cut the slot into the

deck block. Temporarily plug the fin into the slots in

formers F-9 and F-10. Adjust the slot in the deck

block if necessary for a satisfactory fit. Tack glue

the deck block to the fuse but

do not

glue the fin.

Remove the fin and thoroughly glue the deck block

to the fuse with thin CA.

❏

31. Shape the deck block to match the cross-

section on the plan. A razor plane is helpful for this

kind of shaping.

❏

32. Remove the fuselage from the building board.

❏

33. Inspect the structure from the inside. Add

glue to any open joints.

FUSELAGE BOTTOM

❏

1. Cut two of the 24"

outer pushrod guide

tubes

to the lengths required for the rudder and

elevator pushrods (see fuse side view).

❏

2. Roughen the outside of the pushrod tubes

with sandpaper. Slide the tubes through the 3/16"

holes in the formers with reference to the plan.

Securely glue the tubes to all formers they contact.

❏

3. Cut 10" off the

unthreaded end

of a

threaded

pushrod wire

. Cut about eight 5/16" lengths of the

inner pushrod tube

from the material left over from

the inner aileron pushrod. Use rubbing alcohol to

remove any residue from the pushrod wire. Slide the

short lengths of inner tube over the pushrod wire,

spacing them approximately 3" apart. These act as

spacers to support the wire pushrod in the guide tube.

The spacers can be shorter than 5/16" if they are to

hard to push on.

The spacers must not be near the

end of the outer pushrod tube

. Apply a small drop

of thin CA to each spacer if the fit is loose.

❏

4. Screw the nylon

double-ended ball link

onto

the threaded end of the .074" x 24" wire. Make a

22