Top Flite TOPA0101 User Manual

Page 35

❏

4. Cut the hinge slots in the wing and ailerons.

❏

5. Taper the leading edge of the aileron to

match the cross-section on the plan.

❏

6. Make two (four for flaps) 3/4" x 1" horn

reinforcement blocks from leftover 1/8" plywood.

❏

7. Mark the locations of the reinforcement

blocks on the ailerons and flaps (if used) as shown

on the plan. Cut away some of the balsa material

to allow the blocks to be inset flush with the bottom

of the ailerons and flaps. Use 6-minute epoxy to

glue the pieces in position.

❏

8. Blend the reinforcement blocks with a

sanding block.

THIS COMPLETES THE BASIC

CONSTRUCTION SEQUENCE

FINISHING

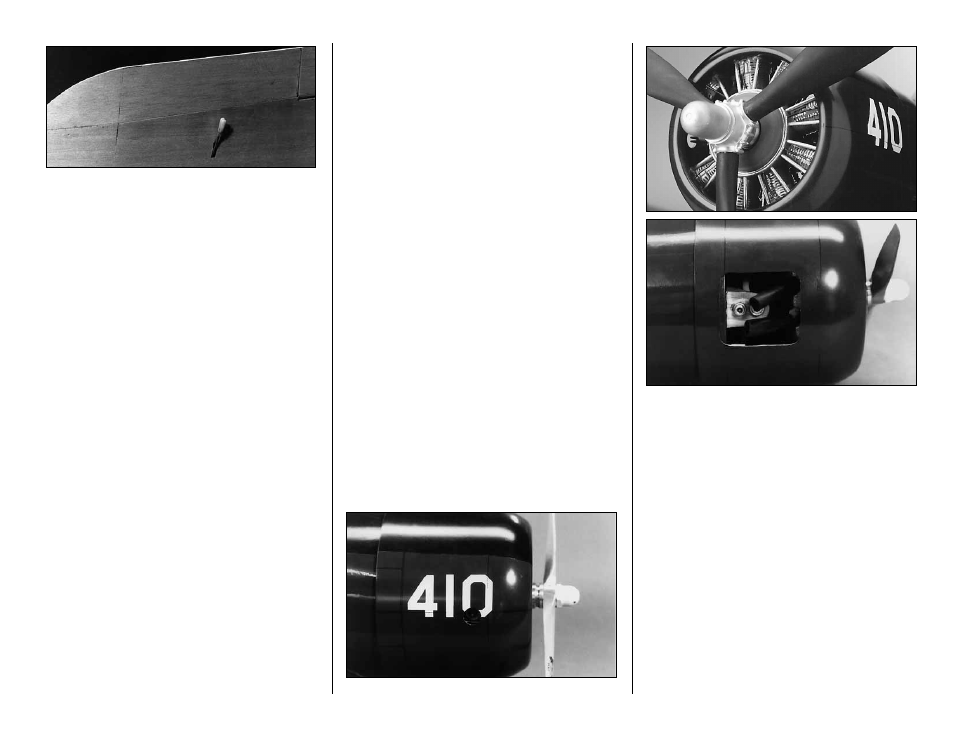

COWL FINISHING

❏

1. Clean the fore and aft cowl pieces with warm

water and a mild detergent to remove any molding

residue. Use rough sandpaper to score areas

where the two pieces are glued together. Test fit

the forward and aft cowl pieces together. It is

easiest to trim any “flash” from the cowl pieces

before they are glued together.

❏

2. While holding the two cowl pieces together,

apply thin CA from the inside and allow it to wick

into the joint.

❏

3. Carefully apply some thin CA to the outside

of the joint. Sand the seam down to the original

level or slightly below. Fill any imperfections with

your favorite filler. Bondo auto body filler can be

used in very small amounts to fill cowling

imperfections. Use of Bondo or similar fillers is

not

recommended for other parts of the model.

❏

4. Sand the entire cowl with 400 grit sandpaper.

❏

5. Test fit the cowl to determine the cooling,

glow plug and exhaust hole locations (see Cooling

Notes section). Cut out the necessary holes. A

Dremel MultiPro is useful here.

❏

6. Fit and glue the baffle in place now (see

Cooling Notes on page 40).

❏

7. Paint the cowling as desired. For best results,

prime and sand the cowl first (see the following

cowl detail photos).

FINAL SANDING

Nearly every imperfection in your wood structure

will show through the covering material. Therefore,

before covering, you should make a final check of

the entire structure. Fix any “dings,” then sand the

entire structure smooth using progressively finer

grades of sandpaper.

FUELPROOFING

Note:

Fuelproofing may be done after covering.

❏

1. Fuelproof the firewall area and the cowl

baffle. Black K&B Superpoxy paint was used for

this on the prototypes.

35