Troubleshooting (cont'd) – Reznor SFT Unit Installation Manual User Manual

Page 23

Form RZ -NA-I-SFT, Page 22

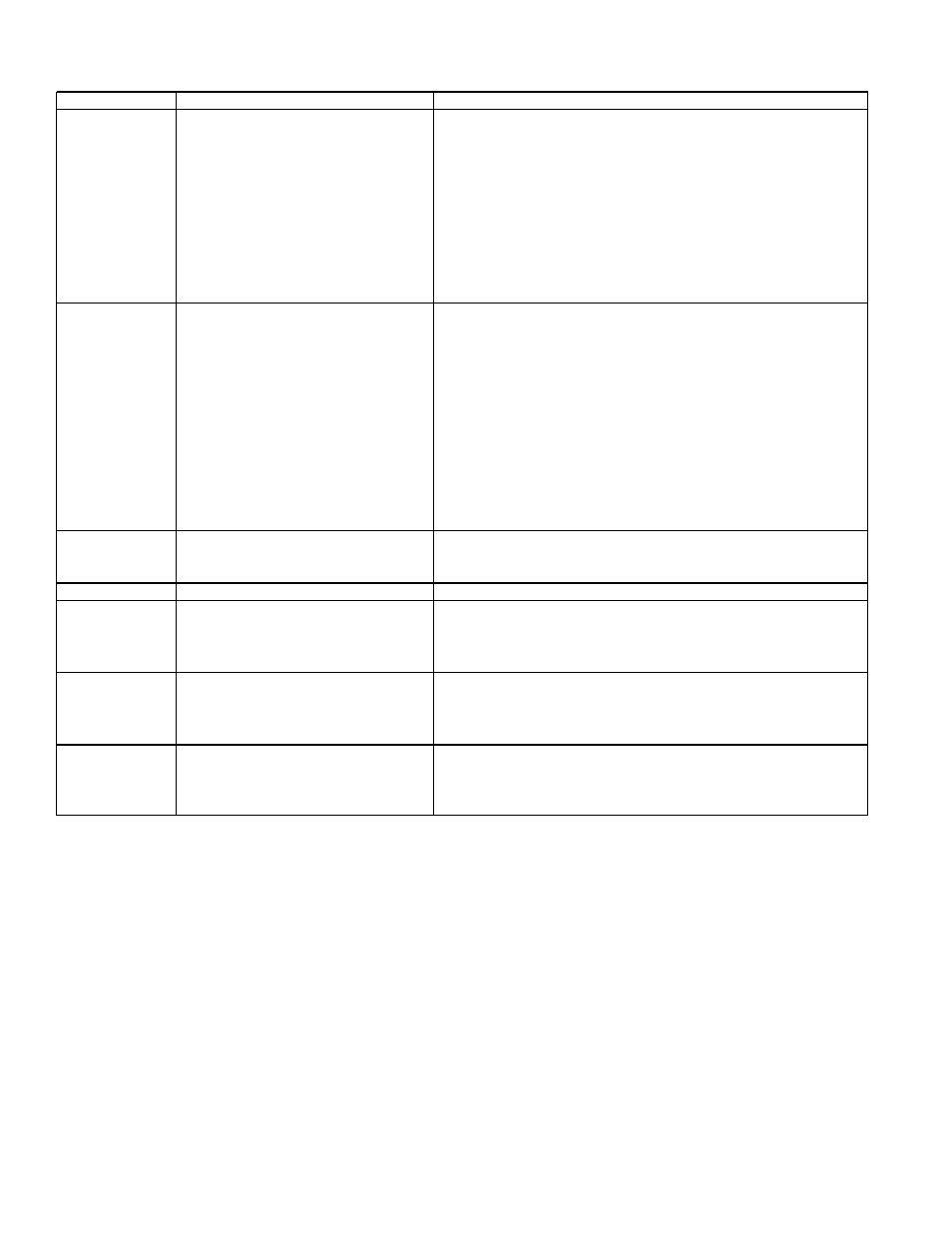

30. Troubleshooting (cont'd)

PROBLEM (cont'd) PROBABLE CAUS E (cont'd)

REMEDY (cont'd)

Burners will not

light (cont'd)

8. Integrated ignition control module does not

power main valve.

8.

a) Loose wire connections

a) Check and tighten all wiring connections.

b) Flame sensor grounded

b) Be certain flame sensor lead is not grounded or insulation or ceramic is not

cracked. Rep lace as required.

c) Incorrect gas p ressure

c) Set sup ply p ressure at 5" w.c. to 14" w.c. for natural gas and 11" w.c. to 14"

w.c. for p rop ane gas.

d) Cracked ceramic at sensor

d) Replace sensor.

9. Flame rollout switch open

a) Air blockage through the unit

a) Check for heat exchanger or vent pip e blockage.

b) Faulty flame rollout switch

b) Replace flame roll out switch.

Burners cycle on

and off

1. Gas pressure too high or too low.

1. Set sup ply p ressure at 5" w.c. to 14" w.c. for natural gas and 11" w.c. to 14"

w.c. for p rop ane gas.

2. Burners not grounded

2. M ake certain integrated ignition control module is grounded to igniter.

3. Ignition control module not grounded.

3. M ake certain integrated ignition control module is grounded to furnace chassis.

4. Faulty integrated ignition control module

4. If 24 volt is available to the integrated ignition control module and all other

causes have been eliminated, rep lace module. DO NOT ATTEMPT TO

REPAIR IGNITION CONTROL MODULE; IT HAS NO FIELD

REPLACEABLE COMPONENTS .

5. Faulty combustion air proving switch.

5. Rep lace combustion air p roving switch.

6. Flame sensor grounded

6. Be certain flame sensor lead is not grounded or insulation or ceramic is not

cracked. Rep lace as required.

7. Cracked ceramic at sensor

7. Rep lace sensor

8. Incorrect p olarity.

8. Reverse 115V line connections at ignition control module.

No heat (Heater

1. Incorrect manifold pressure or orifices.

1. Check manifold p ressure (See Paragrap h 9).

Operating)

2. Cycling on limit control.

2. Check air throughput.

3. Imp rop er thermostat location or adjustment. 3. See thermostat manufacturer's instructions.

Cold air delivered

1. Incorrect manifold pressure.

1. Check manifold p ressure (See Paragrap h 9).

Fan motor will not 1. Circuit open.

1. Check wiring and connections..

run

2. Defective integrated ignition control module. 2. Rep lace module. DO NOT ATTEMPT TO REPAIR IGNITION

CONTROL MODULE; IT HAS NO FIELD REPLACEABLE

3. Defective motor.

3. Rep lace motor.

1. M otor overload device cy cling on and off.

1.

a) Check motor load against motor rating p late. Rep lace motor if needed.

b) Check to be certain that an unauthorized air distribution device has not been

added.

Fan motor cuts

1. Low or high voltage supp ly .

1. Correct electric supp ly.

out on overload

2. Defective motor.

2. Rep lace motor.

3. Poor air flow.

3. Clean motor, fan and fan guard.

4. Defective bearing.

4. Rep lace motor.

Fan motor turns on

and off while

burner is operating

(S ee below)