Troubleshooting, Limit controls, Gas valve – Reznor SFT Unit Installation Manual User Manual

Page 22: Combustion air pressure switch, Vent/combustion air system, Flame rollout switch, Applies to models sft 45-75 only)

Form RZ -NA-I-SFT, Mfg No. 173474 (Rev 6), Page 21

30. Troubleshooting

Check the Ignition control module - The integrated igni-

tion control module monitors the operation of the heater and

includes an LED signal that indicates normal operation and

various abnormal conditions. If the heater fails to operate

properly, check this signal to determine the cause and/or to

eliminate certain causes.

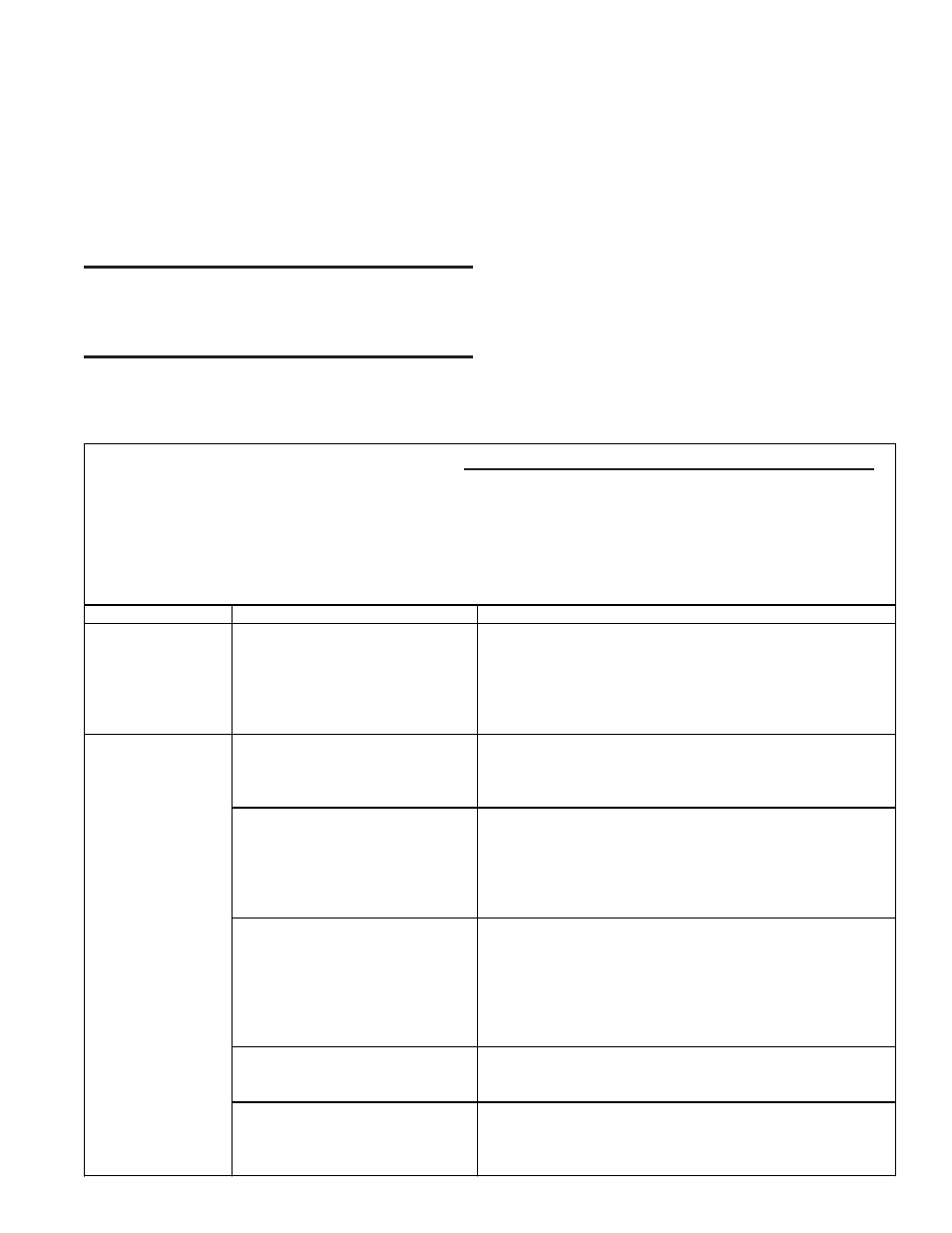

Ignition Control Module LED Codes

Slow Flash . Normal Operation, No call for heat

Fast Flash .. Normal Operation, Call for heat

2 Flashes .... System Lockout, Failed to detect or sustain flame

3 Flashes .... Pressure Switch Open or Closed

4 Flashes .... High Limit or Flame Rollout Switch Open

5 Flashes .... Flame Sensed and Gas Valve not energized

Steady On .. Internal Failure - Replace the ignition control module

25. Limit Controls

If it is determined that a limit control needs replacing, use only the

factory-authorized replacement part that is designed for the size of heater.

To access the limit control on Sizes 45-75, remove the louver assembly

from the front of the heater. On Sizes 100-300, the limit control is

accessible in the control compartment.

For approximate limit locations, see Figure 14 on page 19.

26. Gas Valve

The gas valve requires no field maintenance except careful removal of

external dirt accumulation and checking of wiring connections. Instruc-

tions for testing pressure settings are in Paragraph 10.

WARNING: The operating valve is the primary

safety shutoff. All gas supply lines must be free of

dirt or scale before connecting to the unit to ensure

positive closure. See Hazard Levels, page 2.

27. Combustion Air Pressure

Switch

If it is determined that the pressure switch needs replacing, use only

the factory-authorized replacement part that is designed for this heater.

28. Vent/Combustion Air System

Check at least once a year. Inspection should include all joints, seams,

and the terminal caps. Clean the screen in the vent terminal cap.

Replace any defective parts.

29. Flame Rollout Switch

(Applies

to Models SFT 45-75 only)

If it is determined that the flame rollout switch needs replacing, use

only the factory-authorized replacement part that is designed for the

size of heater. To access the flame rollout switch, disconnect the flex-

ible hose from the burner box (See Figure 14 on page 17).

PROBLEM

PROBABLE CAUS E

REMEDY

Venter motor

1. No p ower to unit.

1. Turn on p ower, check sup p ly fuses or circuit breaker.

will not start

2. No 24 volt p ower to venter relay .

2. Turn up thermostat; check control transformer outp ut.

3. Integrated ignition control module

defective.

3. Rep lace integrated ignition control module. DO NOT ATTEMPT

TO REPAIR IGNITION CONTROL MODULE; IT HAS NO FIELD

REPLACEABLE COMPONENTS .

4. Defective motor.

4. Rep lace motor.

Burners will

1. M anual valve not op en.

1. Op en manual valve.

not light

2. Air in the gas line.

2. Bleed gas line.

3. Gas p ressure too high or too low.

3. Set sup p ly p ressure at 5" w.c. to 14" w.c. for natural gas and 11" w.c.

to 14" w.c. for p rop ane gas.

4. No Sp ark:

4.

a) Loose wire connections

a) Be certain all wire connections are solid.

b) Transformer failure

b) Be sure 24 volts is available.

c) Incorrect sp ark gap .

c) M aintain sp ark gap at 1/8".

d) Sp ark cable shorted to ground.

d) Rep lace worn or grounded sp ark cable.

e) Sp ark electrode shorted to ground

e) Rep lace if ceramic sp ark electrode is cracked or grounded.

f) Burners not grounded

f) M ake certain integrated ignition control module is grounded to igniter.

g) Ignition control module not grounded.

g) M ake certain integrated ignition control module is grounded to furnace

chassis.

h) Faulty integrated ignition control

module

h) If 24 volt is available to the integrated ignition control module and all

other causes have been eliminated, rep lace module. DO NOT

ATTEMPT TO REPAIR IGNITION CONTROL MODULE; IT HAS

NO FIELD REPLACEABLE COMPONENTS .

5. Lockout device interrup ting control

circuit by above causes.

5. Reset lockout by interrup ting control at the thermostat or main

p ower.

6. Faulty combustion air p roving switch.

6. Rep lace combustion air p roving switch.

7. M ain valve not op erating.

7.

a) Defective valve

a) If 24 volt is measured at the valve connections and valve remains

closed, rep lace valve.

b) Loose wire connections

b) Check and tighten all wiring connections.