Vertical terminal instructions - option cc2 – Reznor SDH Option - Installation - Venting Instructions User Manual

Page 9

Form I-SDH-V, P/N 211410 R5, Page 9

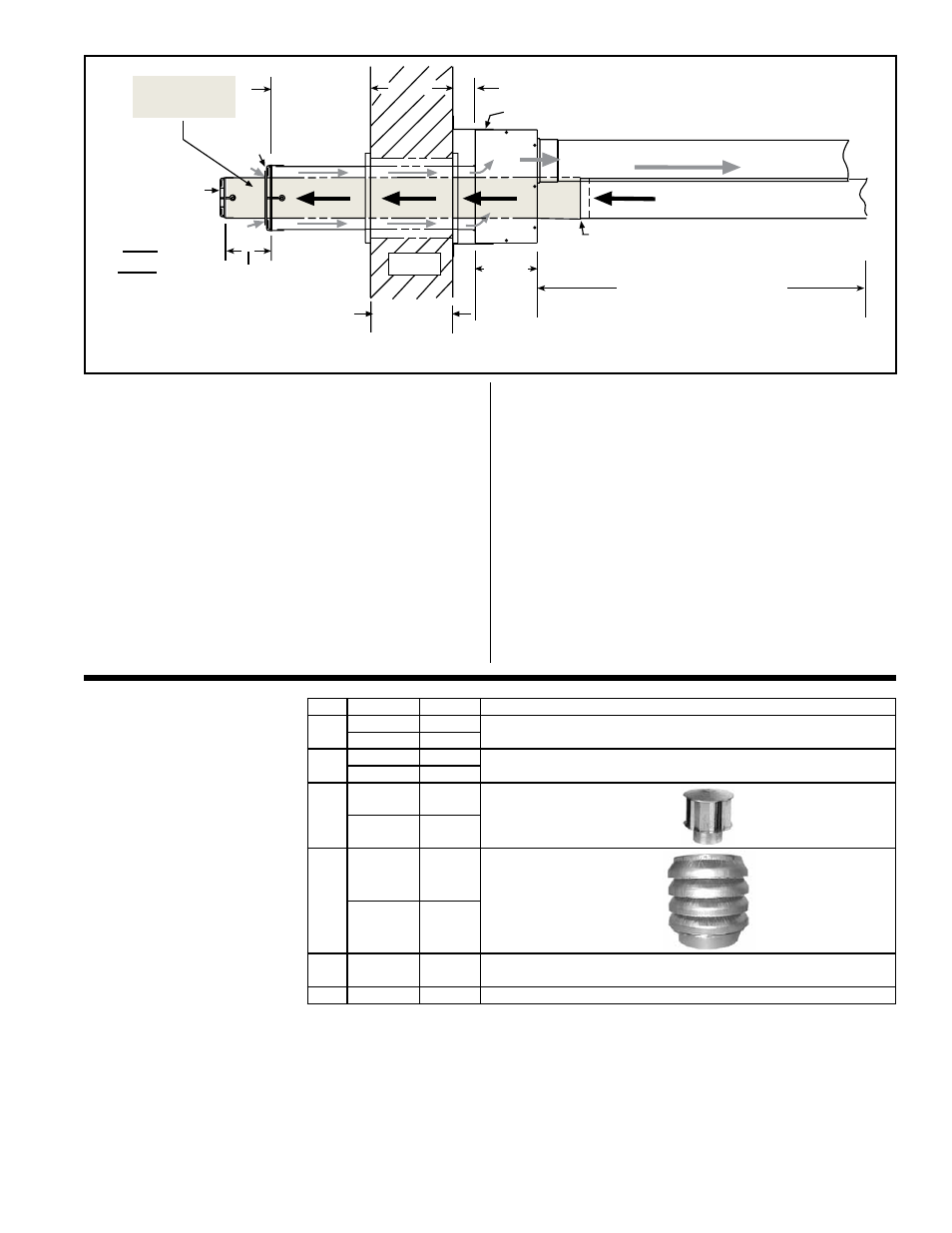

1 (25mm)

Minimum

48 (1219mm)

Maximum

Concentric

Adapter

Box Wid

th

Wall

Exhaust

Grill

Inlet Air

Guard

Combustion Air to Heater (seal joints)

Vent (Flue Exhaust) Pipe

from heater (seal joints)

Heater

Distance between the

Concentric Adapter Box

and the Heater

For Maximum Length, see TABLE 1 on page 2.

Minimum length is 3 ft (.9M).

Attach one-piece terminal end pipe to vent

run no more than 6 (152mm) from the box.

Attach box to wall with brackets.

One-piece

Terminal End

Vent Pipe

Minimum

4 (102mm)

Maximum

16 (406mm)

6

(152

mm)

Minimum

3 (76mm)

Maximum

6 (152mm)

2 (51mm) if wall is combustible

Top

View

b) Install terminal-end vent pipe. Being sure the vent

pipe is in the proper flow direction, slide the end through

the box.

Position the vent pipe so that it will extend between 3”

(76mm) and 6” (152mm) past the end of the combustion

air pipe and no more than 6” (152mm) out of the box

toward the heater. No more than 6” (152mm) from the

box, connect the terminal-end vent pipe to the vent run.

8. Position the exhaust grill over the end of the vent

pipe. See FIGURE 12. Attach the grill to the end of the

vent pipe with the four 1/2” long screws in the kit.

9. Seal the vent pipe to the concentric adapter box.

Verify that the terminal-end section of vent pipe has a

slight downward drop (1/4” per foot/6mm per 305mm)

toward the outside. Use silicone sealant and seal the

circumference of the pipe and the opening of the box.

Seal the area around the pipe completely.

10. Attach the indoor combustion air pipe. Use

sheetmetal screws to attach the single-wall combustion

air pipe run to the collar on the concentric adapter box.

Seal with tape or sealant. If installing a Model SDH Size

150, field-supplied taper-type 5” to 6” (127mm to 152mm)

reducer is required to connect the combustion air pipe to

the collar on the box. See

FIGURE 8, page 6.

Installation of the horizontal vent and combustion air sys-

tem on your separated-combustion unit is complete.

Verify

compliance with all venting installation requirements,

pages 2-6, and FIGURE 12.

TABLE 6 - Parts in the

Vertical Vent Terminal/

Combustion Air

Package (Option CC2)

Components Required -

Factory and Field

VERTICAL

TERMINAL

INSTRUCTIONS -

Option CC2

Field-supplied

installation

requirements:

• Vent pipes - see requirements, page 2

• Combustion air pipes - see requirements, page 2

• Taper-type pipe diameter reducers and/or increasers as required

• Thimble (a thimble is not required if wall is of non-combustible construction)

• Flashing

• Sheetmetal screws, tape, and sealant as required

Before beginning, verify that the kit is at the site and that all components are correct for

the installation. Be sure all required field-supplied parts are available.

Qty

Sizes

P/N

Description

1

75-125

205895 Complete Vertical Vent/Combustion Air Terminal Kit (Same as

Option CC2)

150-400A 205896

1

75-125

205884 Concentric Adapter Box Assy (NOTE: Refer to

FIGURE 5, page

5, and verify diameter of vent pipe opening.)

150-400A 205885

1

75-125

110051 Exhaust (Vent)

Terminal Assembly

150-400A 110052

1

75-125

155635

Combustion Air

Inlet Assembly

150-400A 53330

2

75-400A 207232 Brackets for attaching Concentric Adapter Box (See FIGURE 13,

page 10.)

1

75-400A

53335 Tube of High Temperature Silicone Sealant