Reznor SDH Option - Installation - Venting Instructions User Manual

Page 3

Form I-SDH-V, P/N 211410 R5, Page 3

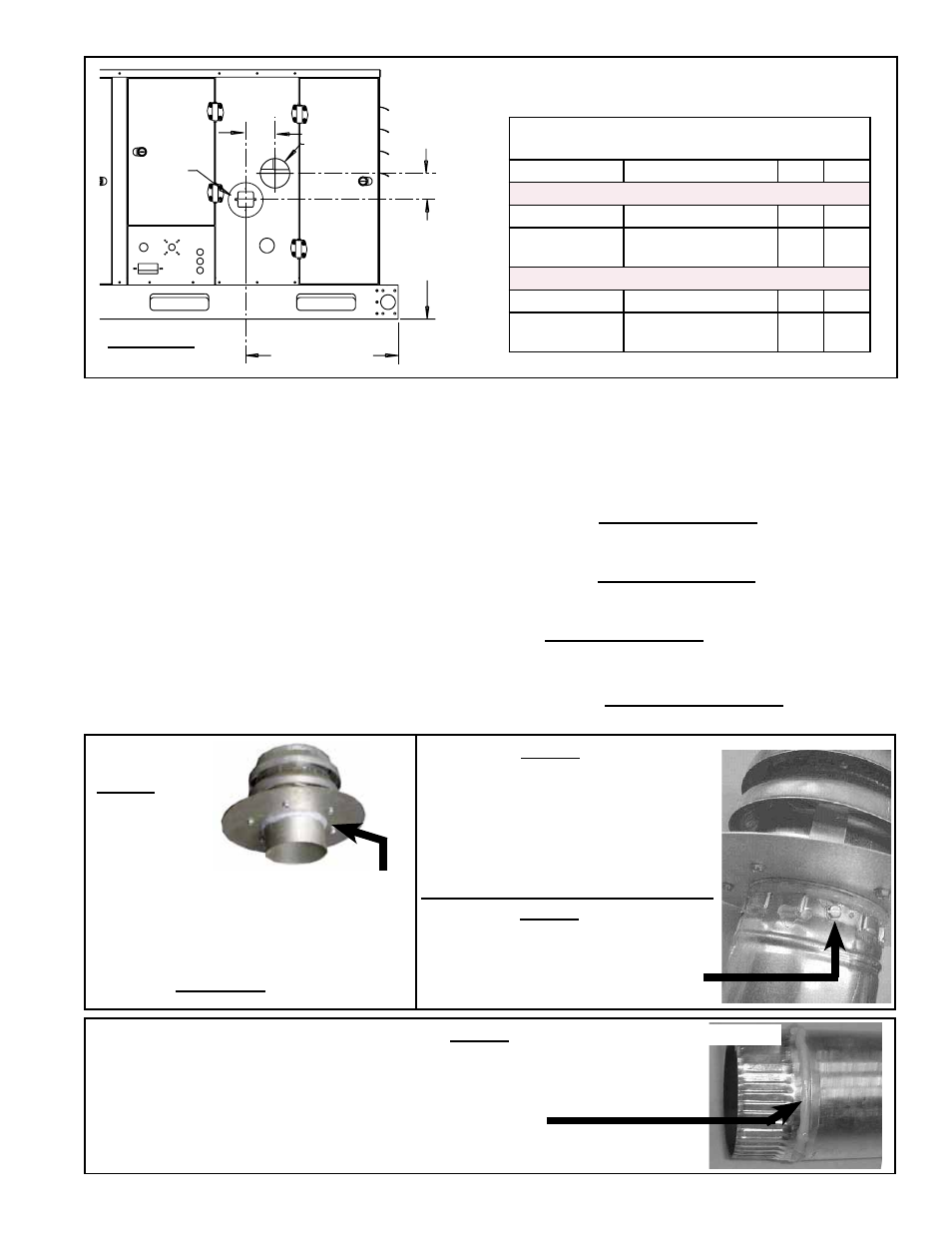

Combustion

Air Inlet

Collar

Venter

Outlet

Sizes 75-150

16-13/16 (427mm)

Sizes 175-400A

17-1/4 (438mm)

Sizes 75-150

20-3/4 (527mm)

Sizes 175-400A

31 (787mm)

Y

X

FIGURE 1 - Locations of Outlet and Inlet Connections

Side View

Location of Inlet Combustion Air Collar (in relation

to vent pipe connection)

Cabinet Sizes

Model SDH Sizes

X

Y

Dimensions (inches)

A, B

75, 100, 125, 150

4

3-5/8

C, D, E

175, 200, 225, 250,

300, 350, 400A

5

4

Dimensions (mm)

A, B

75, 100, 125, 150

102

92

C, D, E

175, 200, 225, 250,

300, 350, 400A

127

102

Provide pipes as specified in

Requirement No. 1, page 2, and seal joints as follows:

• To join sections of Category III pipe, follow the pipe manufacturer’s instructions

for joining and sealing.

• To join sections of single-wall pipe (vent pipe or combustion air pipe), secure

slip-fit pipe connections using sheetmetal screws or rivets. Seal all joints with

aluminum tape or silicone sealant.

• When joining the terminal section of double-wall vent pipe (vertical vent

terminal Option CC2 only) to the vent cap, follow the illustrated step-by-step

instructions in

FIGURE 2.

When joining the terminal section of double-wall vent pipe (vertical vent

terminal Option CC2 only) to the single-wall or Category III vent pipe run,

follow the illustrated step-by-step instructions in

FIGURE 3.

When joining two sections of double-wall vent pipe (vertical vent terminal

only; restrictions apply), follow the pipe manufacturer’s instructions for joining

and sealing vent pipe sections.

4. Joints and Sealing

NOTE: Joints connecting

double-wall pipe apply

only to a vertical vent

terminal (Option CC2

Vertical Vent/Combustion

Air Kit). Horizontal vent

does not require double

wall pipe; see Type of

Pipe requirement on

page 2.

FIGURE 2 - Follow STEPS to join Double-Wall (Type B) Pipe and the Vent Terminal Cap (applies only

to vertical vent/combustion air kit Option CC2)

FIGURE 2 -

STEP 1

Place a continual 3/8” bead of silicone

sealant around the circumference of the vent

cap collar. This will prevent any water inside

the vent cap from running down the double-

wall pipe.

Do STEP 2 immediately following STEP 1.

FIGURE 2 - STEP 2

Insert the collar on the vent cap inside the

inner wall of the double-wall pipe. Insert

as far as possible. Add additional silicone

sealant to fully close any gaps between

the vent cap and the double wall pipe.

This is necessary to prevent water from

entering the double-wall pipe.

Secure the vent cap to the double-wall

pipe by drilling and inserting a 3/4” long

sheetmetal screw into the vent cap

collar. Do not overtighten screw.

FIGURE 2 - STEP 3

FIGURE 3 - Follow STEPS

to join Double-Wall (Type

B) Pipe (VERTICAL

VENT Option CC2 ONLY)

to Single-Wall Pipe, to

Category III Pipe, or to a

Taper-type Connector

FIGURE 3 - STEP 1

On the single-wall pipe, Category III pipe,

or taper-type connector, place a continual

1/4” bead of silicone sealant around the

circumference.

Do STEP 2 (next page) immediately

following STEP 1.

Single-Wall Vent Pipe