Reznor SDH Option - Installation - Venting Instructions User Manual

Page 8

Form I-SDH-V, P/N 211410 R5, Page 8

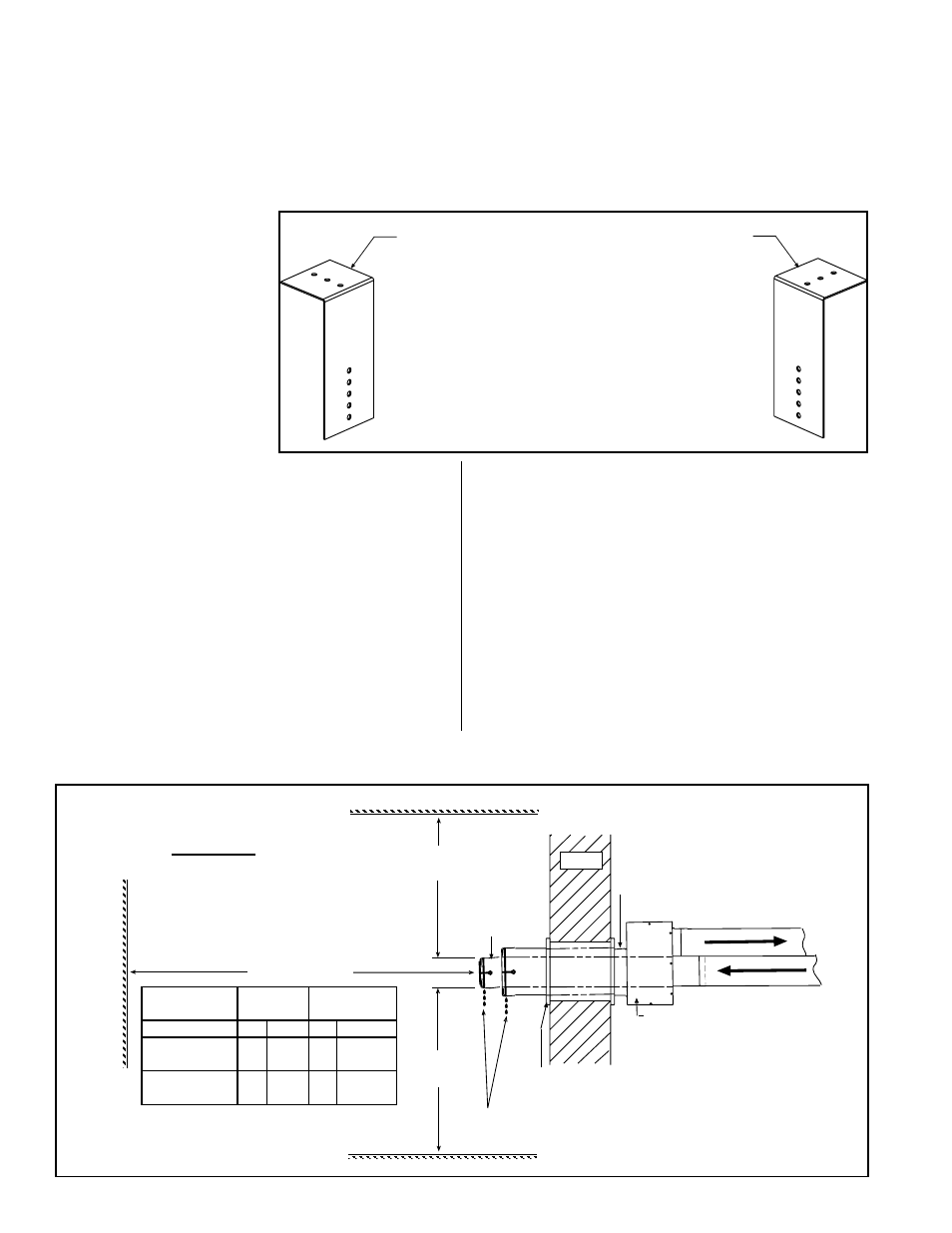

FIGURE 11 - Brackets

for Attaching the

Concentric Adapter Box

to the Wall

1) Attach the Brackets to the Box - The 6 (152mm)

portion of each bracket is designed with five 7/32

diameter holes so that attachment to the box can

be adjusted.

If the wall is combustible, position brackets to allow for a 2

(51mm) clearance between the box and the wall. Adjust

bracket attachment to allow for the slight downward pitch of

the terminal vent pipe.

After careful positioning, use sheetmetal screws to attach the

brackets. NOTE: If any holes are made in the box in error,

they must be sealed.

2) Attach the Box to the Wall (Step 5)

When the box is attached to the wall in Step 5, use

the 2-1/2 (64mm) portion of the brackets. To adjust to

construction each bracket has three 7/32 diameter holes.

HORIZONTAL

TERMINAL

INSTRUCTIONS -

Option CC6 (cont’d)

Secure Concentric Adapter

Box to wall with brackets.

Adjust so that the box has a

slight downward slope to the

outside.

One-piece

Terminal End

Vent Pipe -

Pitch to

Drain

Thimble

Combustion Air Pipe

- Pitch to Drain

Y

Minimum

3 ft (1M)

Minimum

X - Minimum*

Adjoining Building

Building Projection

Building Overhang - Maximum 24 (610mm)

Wall

Rain water should drain out

and not roll into the pipes.

Side View

FIGURE 12 - Installation of a Typical Separated-Combustion Unit with Horizontal Vent Terminal and

Combustion Air Pipe (Option CC6)

Model SDH

Sizes

X*

Y

75, 100

4 ft 1.2 M 18" 457 mm

125, 150,

175, 200, 225 4 ft 1.2 M 24" 610 mm

250, 300,

350, 400A

6 ft 1.8 M 36" 914 mm

*Minimum - Check for and comply with

local Codes.

Installation Instructions

for Horizontal Kit

Option CC6 (cont’d)

(in compliance with

requirements on

pages 2-6)

3. Prepare a clearance hole through the outside wall for the combustion air

pipe -- a 6” (152mm) diameter pipe for Sizes 75-125 or an 8” (203mm) diameter

pipe for Sizes 150-400A. Outside wall construction thickness should be 1” (25mm)

minimum and 48” (1219 maximum). The larger diameter combustion air pipe serves

as clearance for the vent pipe on non-combustible construction. A thimble may be

required depending on wall construction and/or local codes.

4. Prepare the Concentric Adapter Box

a) Attach the brackets to the box. Follow the instructions in FIGURE 11.

b) Attach the outside portion of the combustion air

pipe to the box. Determine the length by measuring the

bracket length from box to wall, plus the wall thickness,

plus 4-16” (102-406 mm) beyond the wall. (The inlet air

pipe should extend beyond the outside wall a minimum of

4” (102mm) to a maximum or 16” (406mm).

Attach the inlet air pipe to the collar of the concentric

adapter with sheetmetal screws and seal.

5. Attach the concentric adapter box to the wall. Insert

the combustion air pipe out through the wall.

Attach the

brackets to the wall (

FIGURE 11). On the outside, caulk

or flash the inlet air pipe. Flashing is field-supplied.

6. On the outside, position the inlet guard over the

end of the combustion air pipe. See

FIGURE 12. Attach

the guard to the inlet air pipe with the four 1/2” long

screws provided.

7. Determine length and install the “terminal-end”

vent pipe.

a) Determine length of pipe. The length of the

continuous piece of terminal-end vent pipe is determined

by the installation within the maximum and minimum

requirements. See

FIGURE 12 to determine lengths of

each segment and calculate the total length required. The

“terminal-end” vent pipe extending through the box and

concentric through the inlet air pipe

must be one piece

of vent pipe without joints. The connection to the vent

pipe run, must be a maximum of 6” (152mm) from the

heater side of the box.