0 gas supply -10, 1 gas supply line, 0 gas supply – Reznor RIHVL Unit Installation Manual User Manual

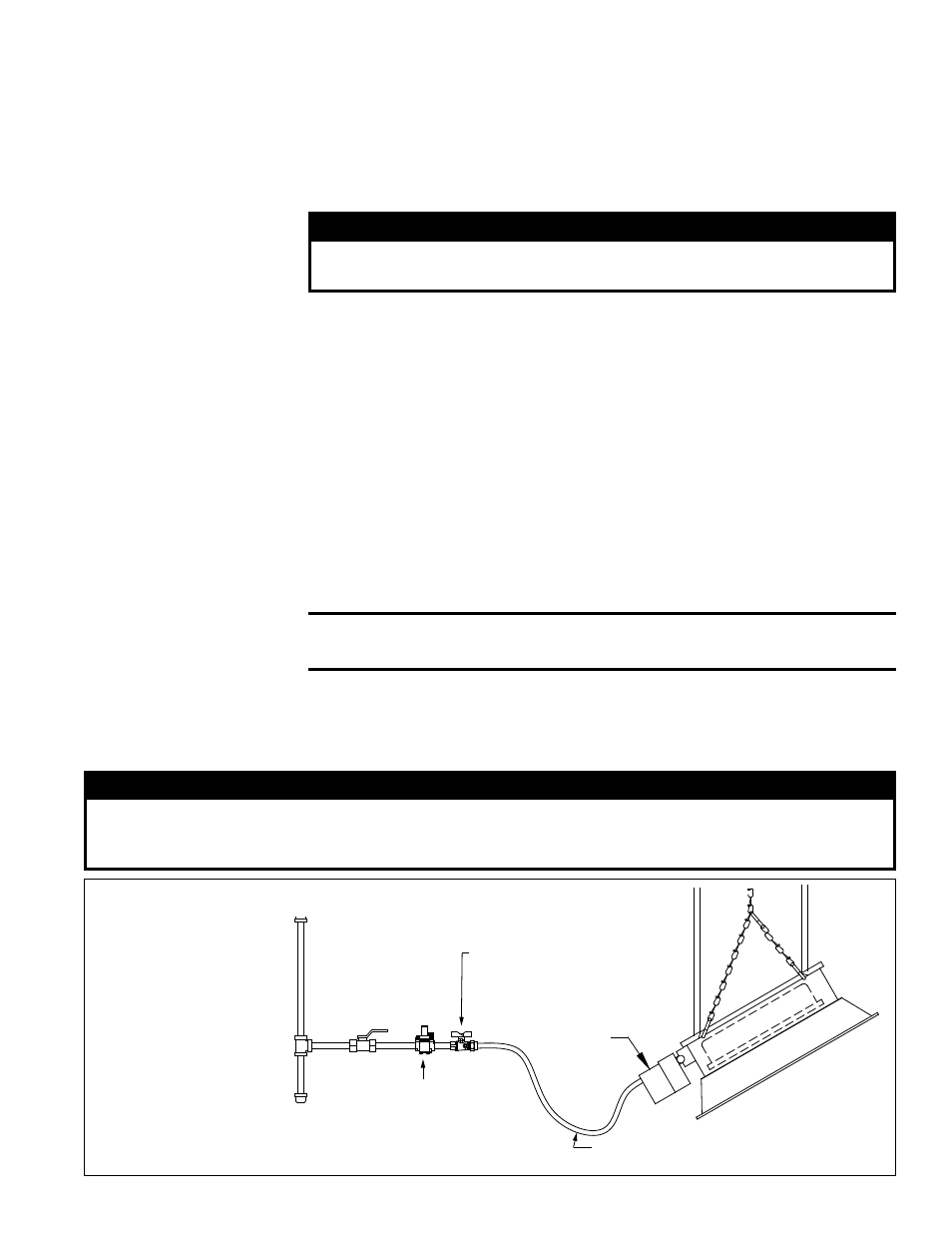

Page 9: 1 gas supply line (refer to figure 6 .)

If a heater is located in an aircraft hangar or near overhead doors, it should be rigidly

mounted to prevent swinging.

The installer is responsible for suspension of the heater.

Under no circumstances

should either the gas supply line or electrical supply line to the unit be used to

provide assistance in suspension. Do not run any gas or electric service lines

above or below the heater or near the path of the flue products.

Gas

Supply

6” (15mm)

Drip Leg

Manual

Gas Valve

Pressure regulator

required when supply

pressure exceeds

14” (35cm) w.c.

Gas Cock with plugged

pressure tap (component

of the agency-approved

flexible connector shown

here)

Agency-approved Flexible Connector

(if permitted by local code)

Gas Valve

with manifold

pressure tap

FIGURE 5 -

Gas Supply

Connections -

All components

upstream of the

gas valve on the

unit are field-

supplied.

6.0 Gas Supply

6.1 Gas Supply Line (Refer to FIGURE 6.)

WARNINGS

DO NOT install any gas piping in heat zones.

DO NOT use gas supply piping to support the heater.

•

All piping must be installed according to local codes. Use new clean pipe. Inspect

and clean out any chips or debris before installing the pipe and fittings.

•

Piping joint compound must be resistant to the action of liquefied petroleum gases.

•

An agency-approved flexible connection between the supply line and the heater

may only be used if permitted by local code. It is recommended that either the

piping or the mounting be flexible to prevent fatigue failure from vibration and/or

thermal expansion.

•

A first-stage pressure regulator is required when gas supply pressure exceeds 14"

(35cm) w.c. If a pressure regulator is required, be sure that it is installed in the gas

line with the arrow indicating gas flow pointing in the proper direction.

•

An over-pressure protection device may be required in some jurisdictions.

•

Install a 6" (152mm) drip-leg trap at the inlet connection.

•

Install a 1/8" (32mm) NPT plugged tap, accessible for text gauge connection

immediately upstream of the gas supply connection to the heater.

•

Do not subject gas pressure regulators, flex connectors, and gas cocks on the

heater to test pressures over 14" w.c. while checking supply piping for leaks.

CAUTION: Isolate the heater from the gas supply line during high

pressure leak testing of gas supply piping.

•

All piping joints must be tested for leaks with a non-corrosive leak detecting

solution.

•

Always use two wrenches when mating pipe connections to the heater. Excessive

torque on the manifold may misalign gas orifices causing heater to malfunction.

•

Purge all gas supply lines of air completely before attempting to ignite the heater.

WARNING

All components of a gas supply system must be leak tested prior to placing equipment

into service. Use a non-corrosive leak detecting solution. Never test for leaks with an open

flame. See Hazard Levels, page 2.

P/N 131793R10, Page 9