3 blowers, belts and drives – Reznor RBL (Cabinet Blower) Unit Installation Manual User Manual

Page 9

Form I-RBL, P/N163219R2, Page 9

CAUTION: An

external duct system

static pressure not

within the limits

shown on the rating

plate, or improper

motor pulley or belt

adjustment, may

overload the motor.

5.3 Blowers, Belts and Drives

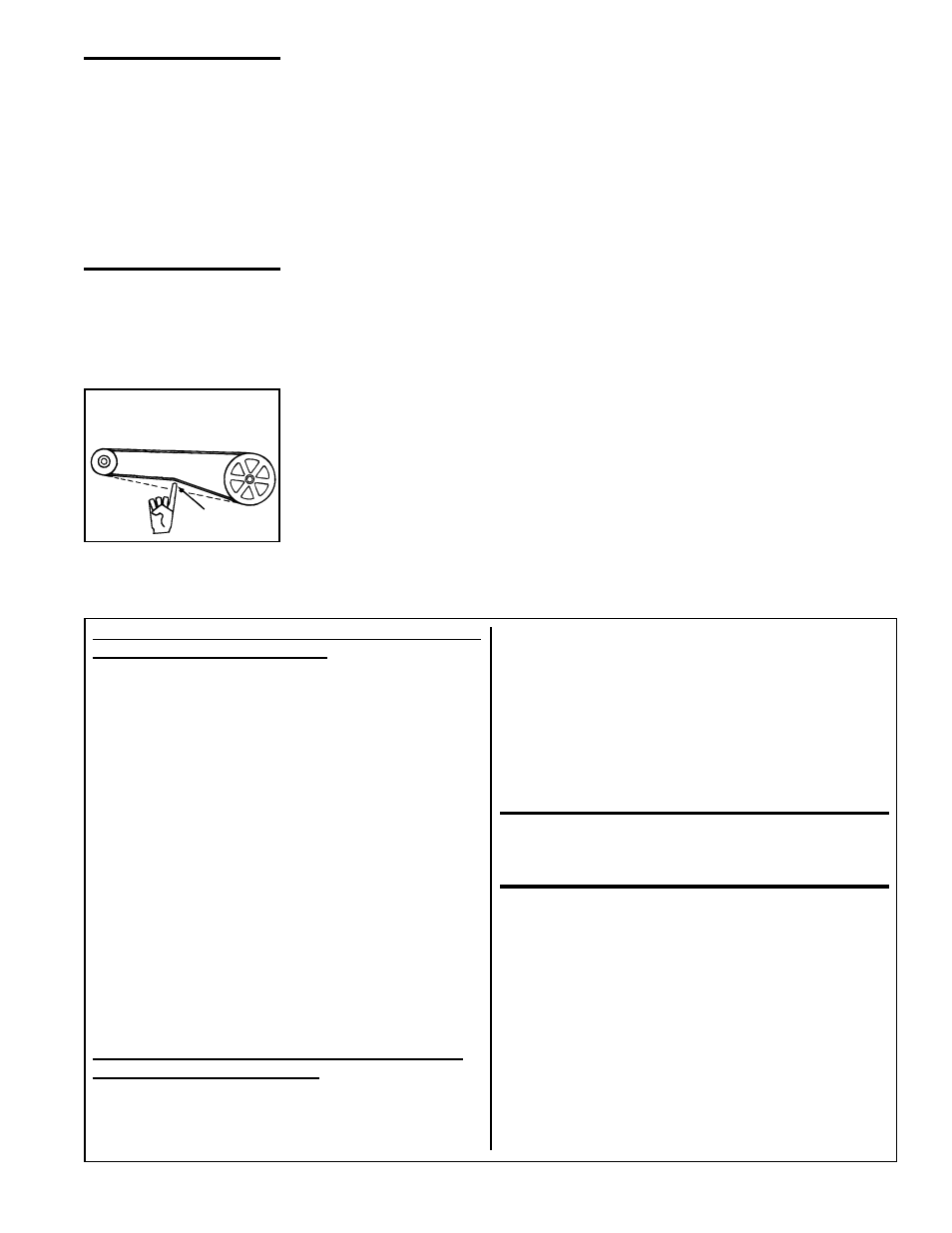

Check belt tension. Proper belt tension is important to the long life of the belt and

motor. A loose belt will cause wear and slippage. Too much tension will cause exces-

sive motor and blower bearing wear. Adjust the belt tension by turning the adjusting

screw on the motor base until the belt can be depressed 3/4" (19mm). (See

FIGURE

14.) After correct tension is achieved, re-tighten the locknut on the adjustment screw.

Be sure that the belt is aligned in the pulleys.

Adjusting Blower Speed - The system is set at the factory for the RPM required to

meet the CFM and external static pressure specified on the order. If estimated external

static pressure is incorrect, or changes were made to the duct system, the blower RPM

may have to be adjusted.

Motors are equipped with adjustable pitch pulleys which permit adjustment of blower

speed.

3/4 (19mm)

FIGURE 14 -

Check Belt Tension

D. No warm air duct should come in contact with masonry walls. Insulate around all

air ducts through masonry walls with not less than 1/2 inch (13mm) of insulation.

E. Insulate all exposed warm air ducts passing through an unheated space with at

least 1/2 inch (13mm) thickness of insulation.

F. For optional bottom openings, insert ducts from below roof deck through roof open-

ing into cabinet. Form 1" (25mm) flanges, fold over, and fasten with sheetmetal

screws. Gain access by removing side panels from blower and downturn plenum

sections.

G. Duct Supports -- Suspend all ducts securely from adjacent buildings members. Do

not support ducts from unit duct connections.

H. Duct Sizing -- Proper sizing of the warm air ductwork is necessary to ensure a

satisfactory heating installation. The recognized authority for such information is

the Air Conditioning Contractors Association, 2800 Shirlington Road, Suite 300,

Arlington, VA 20036 (www.acca.org). A manual covering duct sizing in detail may

be purchased directly from them.

To make adjustments to units with less than a 5HP

motor, follow these instructions.

1. Loosen belt tension and remove the belt.

2. Loosen the set screw on the side of the pulley away

from the motor.

3.

To increase the blower speed, turn the adjustable

half of the pulley inward.

To decrease the blower

speed, turn the adjustable half of the pulley outward.

One turn of the pulley will change the speed 8-10%.

4. Tighten the set screw on the flat portion of the pulley

shaft.

5. Replace the belt and adjust the belt tension. Adjust

tension by turning the adjusting screw on the motor

base until the belt can be depressed 3/4". (See

FIGURE 14.) Re-tighten the lock nut on the adjusting

screw. Be sure that the belts are aligned in the pulley

grooves properly and are not angled from pulley to

pulley.

6. Check the motor amps with an amp meter. The

maximum motor amp rating on the motor nameplate

must not be exceeded.

For units with 5 HP and larger motor, follow these

instructions for adjusting RPM:

1. Slack off all belt tension by moving motor towards

driven shaft until belts are free of grooves. For easiest

adjustment, remove the belts from the grooves.

2. On the outer locking ring, locate the two locking

screws that are directly across from each other.

Loosen these two screws, but do not remove them.

Do not loosen any other screws.

3. Adjust sheave to desired pitch diameter by turning

the outer locking ring. One complete turn of the

outer locking ring will result in .233" change in pitch

diameter. To decrease blower speed, increase

diameter; to increase blower speed, decrease

diameter.

CAUTION: Sheaves should not be adjusted in

either direction to the point where movable and

stationary flanges are in contact.

4. After completing adjustment, tighten both locking

screws in the outer locking ring (loosened in Step 2).

5. Replace belts and move motor away from the driven

shaft to apply sufficient belt tension to prevent

slippage. (See

FIGURE 14.) Proper belt tension is

important to the long life of the belt and motor. A

loose belt will cause wear and slippage. Too much

tension will cause excessive motor and blower

bearing wear. Be sure that the belts are aligned in

the pulley grooves and are not angled from pulley to

pulley.

6. Check motor amps with an amp meter. The maximum

motor amp rating on the nameplate must not be

exceeded.