Installation instructions for pressure null switch – Reznor RBL (Cabinet Blower) Unit Installation Manual User Manual

Page 7

Form I-RBL, P/N163219R2, Page 7

Outside Air

Damper

CLOSED

Return Air

Damper

OPEN

Rod for Outside

Air Damper

Set Screw

Outside Air

Damper Arm

Return Air

Damper Arm

Rod for Return

Air Damper

Damper

Motor

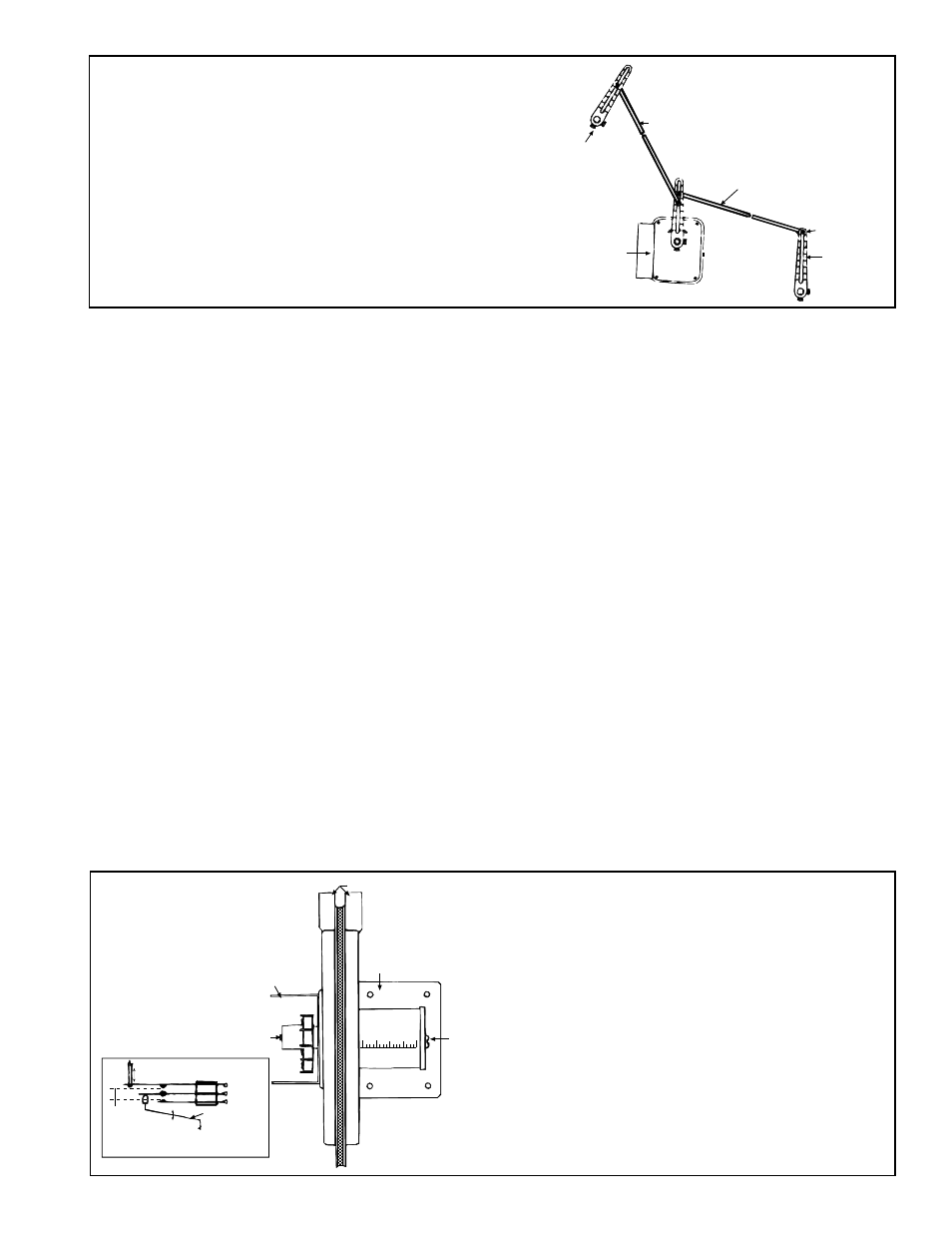

Damper Linkage Instructions -- When units are equipped

with dampers, the dampers are closed during shipment.

When there are both return air and outside air dampers, the

return damper linkage must be adjusted prior to use.

1. Loosen the set screw on the return air damper rod at the

damper arm.

2. Manually open the return air dampers. While the dampers

are opening, the damper rod and arm will automatically

move to their correct positions.

3. Tighten the set screw.

FIGURE 11 - Example of Outside Air and Return Air

Damper Linkage

Pressure Null Switch

(Used to control

Outside Air Dampers in

Inlet Air Option AR23)

The pressure null switch used in Option AR23 is a Dwyer #1640-0 with a range of .01-

.20" w.c. It is shipped separately for field installation. Refer to the following paragraphs

and the manufacturer's installation instructions included with the switch.

Description and Application (See FIGURE 12) - The pressure null switch is a dia-

phragm operated differential pressure switch used in makeup air applications to con-

trol building pressure. It maintains a selected positive or negative pressure setpoint by

changing the amount of outside air being introduced to the building through the modu-

lating outside air dampers. As more pressure is required in the building, the pressure

null switch activates the damper motor driving the outside air damper towards the full

open position and the recirculated air damper towards the closed position. Conversely,

as less pressure is required, the switch drives the dampers in the opposite direction.

Installation Instructions for Pressure Null Switch

1. Select an indoor location free from excessive vibration where oil or water will

not drip onto the switch and where ambient temperature will be within a range of

-30°F (dry air) to 110°F.

2. Mount the switch with the diaphragm in a vertical plane. The switch is position

sensitive and is calibrated to operate properly when the diaphragm is vertical.

Mount switch securely.

3. Connect the pressure taps on the top of the switch to sources of air pressure

differential. Metal tubing with 1/4" O.D. is recommended, but any tubing system

which will not unduly restrict the air flow may be used. To maintain a positive

building pressure, vent the low pressure tap to the outdoors and allow the

high pressure tap to monitor building pressure. To maintain a negative building

pressure, reverse the functions of the high and low pressure taps. In either case,

be sure that the outdoor vent is protected from the wind and screened from

insects.

4. Adjustment of the Switch - The "HIGH" actuation point of the null switch is

indicated on a calibrated scale secured to the transparent range screw enclosure.

Building pressure is set by turning the adjustment screw. The "Low" actuation

Electric Box

Span

Adjust

Screw

Mounting Plate

Pressure Taps

Low

High

Pressure

Adjust

Screw

Span of

floating

contact

Increasing

Decreasing

Linkage to

Diaphragm

Low

Common

High

Span Adjustment

Switching action in the pressure null

switch

IMPORTANT: To eliminate shipping damage to

the switch contacts, the manufacturer reduced

the span adjustment to zero before shipping. The

span should be adjusted prior to using the switch.

(If the switch has been installed, disconnect the

vent tube so that the null switch is in a neutral

position.) Remove the electrical box cover and

while observing the contacts, turn the span

adjustment screw slowly in a clockwise direction.

Continue turning the adjustment screw until you

are able to see gaps between the common and

both the low and high contacts. A minimum gap

provides the greatest sensitivity. The wider the

gap the lower the sensitivity.

FIGURE 12 - Pressure

Null Switch (used with

Inlet Air Option AR23)