LAARS Rheos RHCV - Install and Operating Manual User Manual

Page 9

Rheos Boiler and Water Heater

Page 9

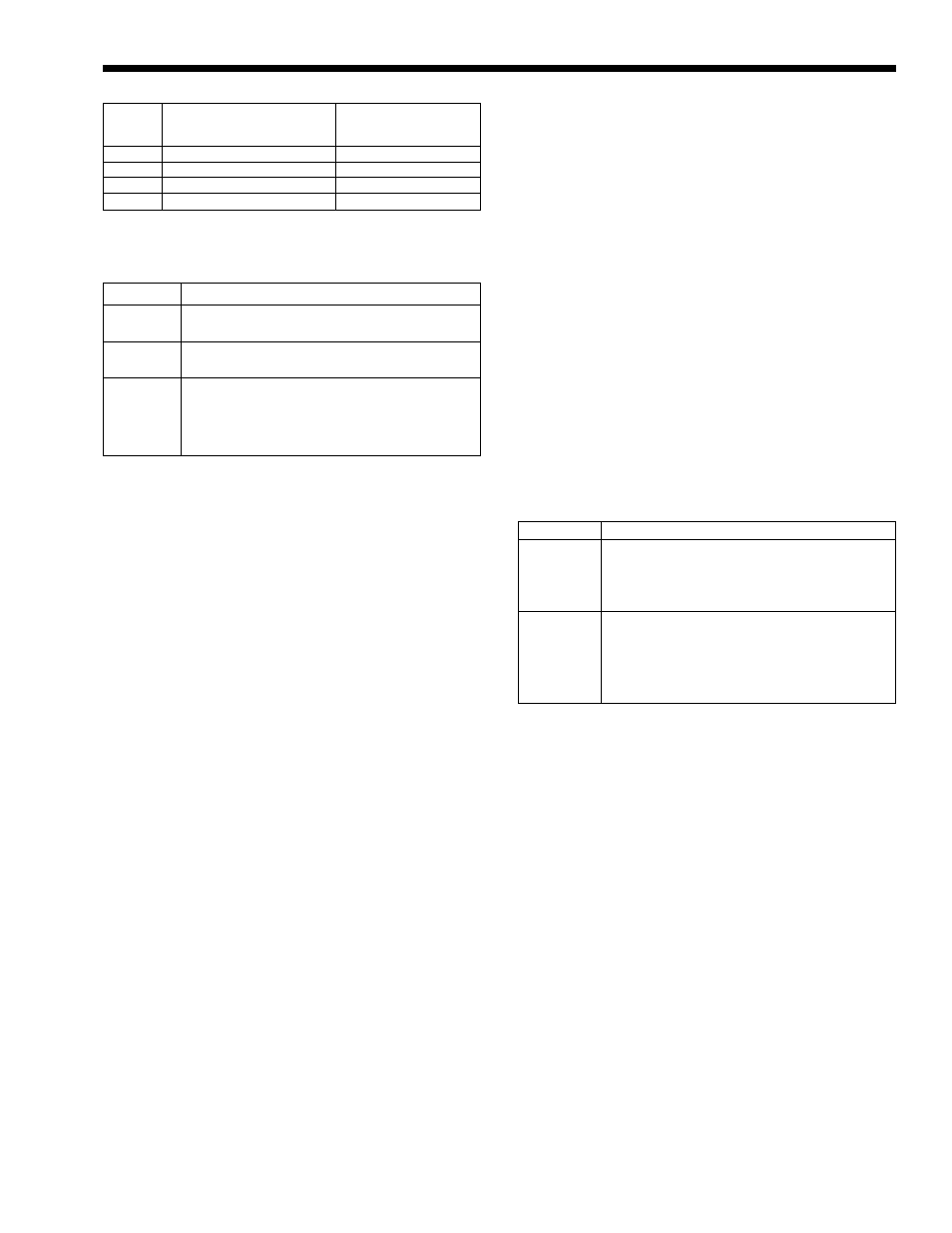

Model

Horizontal Combustion

Horizontal Vent

Air Terminal

Terminal

1200

20260701

D2004500

1600

20260703

D2004500

2000

20260703

D2004600

2400

20260703

D2006200

Table 4. Horizontal Vent and Air Terminals

For Indoor Installations.

Term

Description

Pipe

Single-wall galvanized steel pipe, 24 gauge

minimum (sized per section 1.9)

Joint

Permanent duct tape or aluminum tape

Sealing

Insulation Not required, but recommended R5 insulation

for cold installations (consult American Society

of Heating, Refrigerating, and Air Conditioning

Engineers (ASHRAE) handbook)

Table 5. Required Combustion Air Piping Material.

The connection for the intake air pipe is in the

back of the unit. Take the plate off the back to reveal

the collar on the filter box. Run a bead of silicone

around the collar and slide the pipe over the collar.

Secure with sheet metal screws.

In addition to air needed for combustion, air

shall also be supplied for ventilation, including all air

required for comfort and proper working conditions

for personnel. The Rheos loses less than 1 percent of

its input rating to the room, but other heat sources may

be present.

2.2 Venting

The Rheos is a Category IV appliance and must

be installed with a stainless steel venting system

that complies with the UL 1738 Standard (see Table

6). It must be installed per this installation manual

and the venting system manufacturer’s Installation

Instructions. The unit’s vent can terminate through the

roof, or through an outside wall. It can be installed

through walls that are from 3" (7.6cm) to 12" (30cm)

in thickness.

See Table 3 to select the appropriate vent pipe

diameter. The first section of venting attached to the

boiler must include a condensate drain fitting and

condensate trap. Route the vent pipe to the heater

as directly as possible. Seal all joints and provide

adequate hangers as required in the venting system

manufacturer’s Installation Instructions. Horizontal

portions of the venting system must be supported to

prevent sagging and may not have any low sections

that could trap condensate. The unit must not support

the weight of the vent pipe. Horizontal runs must slope

upwards not less than ¼ inch per foot (21mm/m) from

the unit to the vent terminal. Up to five elbows can

be used with the 50 feet (15.2m) of pipe. Subtract 10

allowable linear feet for every additional elbow used.

IMPORTANT NOTE ABOUT COMMON VENTING:

A single vent that is shared by multiple Rheos

units MUST be engineered by a competent venting

specialist, and involves the selection of draft inducing

equipment, hardware and controls to properly balance

flue gas pressures. Do not common vent Rheos

units unless the vent system meets this requirement.

Rheos units are never permitted to share a vent with

Category I applliances.

For outdoor applications, see Section 1.5.

Condensate Drain Connection: A condensate

drain connection shall be provided on the first section

of venting attached to the boiler. Connect a clear

plastic tube between that drain connection on the

vent and a floor drain (or optional condensate pump

if a floor drain is not accessible). The plastic tube

shall be formed into a loop (trap) to drain condensate

that collects in the vent system without permitting

flue gases to escape. The condensate drain must be

installed so as to prevent accumulation of condensate.

Consult local codes for disposal method.

Term

Description

Venting

Heat-Fab®, Inc. Saf-T Vent®GC or CI,

System

Metal-Fab®, Inc. Corr/Guard, or

equivalent sealed stainless steel

system certified to UL1738.

Insulation

Not required, but recommended R5

insulation with protective cover for cold

installations (consult American Society of

Heating, Refrigerating, and Air Conditioning

Engineers (ASHRAE) handbook)

Table 6. Required Venting Material.

2.3 Locating Vent & Combustion Air

Terminals

2.3.1 Side Wall Vent Terminal

The appropriate Laars side wall vent hood must

be used, and is listed in the installation and operation

manual. The terminal provides a means of installing

the vent piping through the building wall, and must

be located in accordance with ANSI Z223.1/NFPA 54

and applicable local codes. In Canada, the installation

must be in accordance with CSA B149.1 or .2 and

local applicable codes. Consider the following when

installing the terminal:

1. The figure in this addendum shows the

requirements for mechanical vent terminal

clearances for the U.S. and Canada.

2. Vent terminals for condensing appliances or

appliances with condensing vents are not

permitted to terminate above a public walkway,

or over an area where condensate or vapor could

create a nuisance or hazard.