LAARS Rheos RHCV - Install and Operating Manual User Manual

Page 13

Rheos Boiler and Water Heater

Page 13

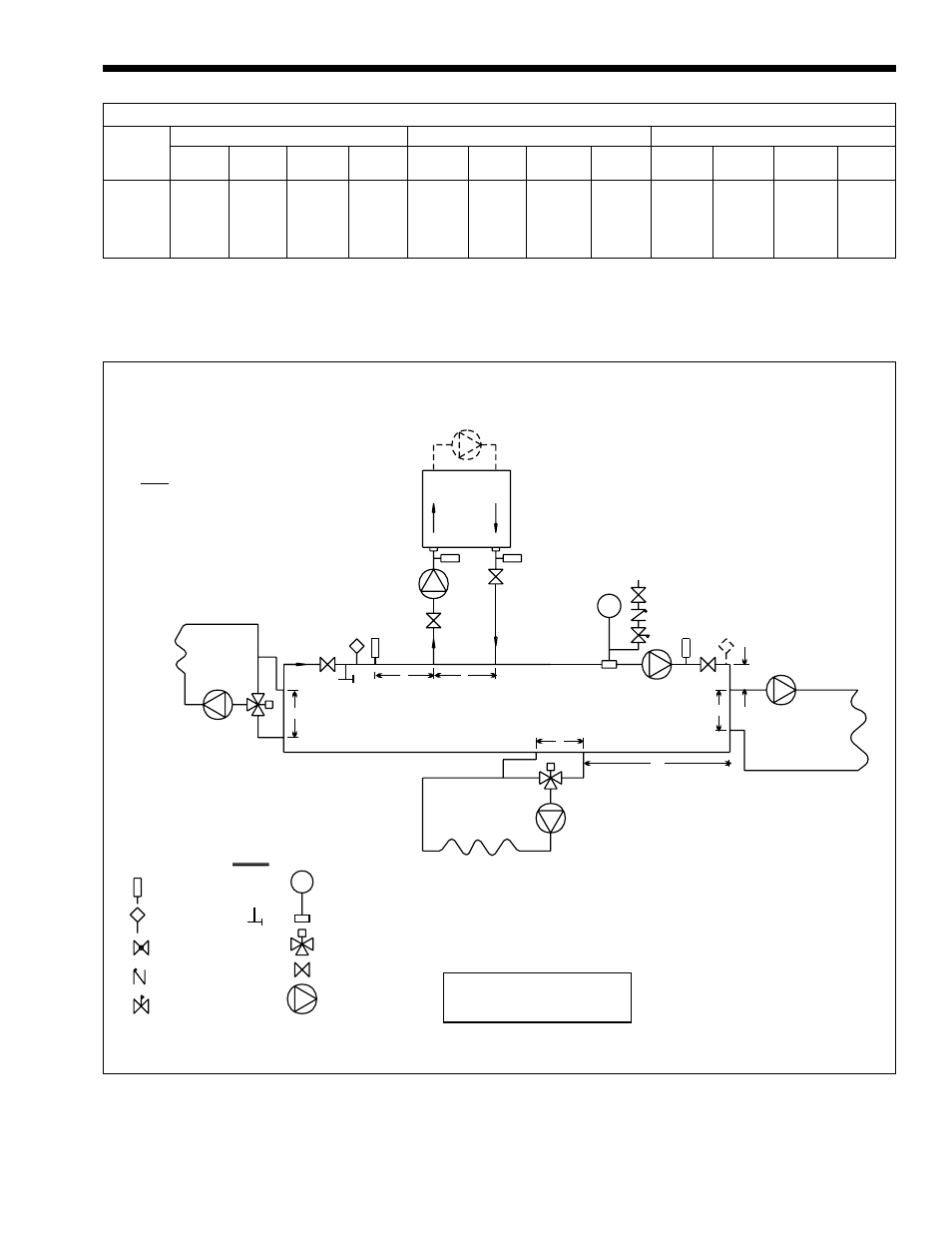

THERMOMETER

GLOBE VALVE

CHECK VALVE

PRESSURE REDUCING VALVE

W/ FAST FILL BYPASS

EXPANSION TANK

WITH AIR SCOOP AND

AUTO AIR VENT

PUMP

LEGEND

VALVE

TEMPERATURE

SENSOR

3-WAY VALVE

PURGE

VALVE

INSTALL AIR VENTS AT HIGH POINTS IN SYSTEM

PIPING & SIZING OF EXPANSION TANK

PER TANK MANUFACTURER'S INSTRUCTIONS

PRIMARY/SECONDARY MANDITORY FOR ALL

VARIABLE FLOW SYSTEMS

BOILER CIRC. PUMP SIZED FOR FLOW THROUGH BOILER

BOILER CIRC. PUMP TO BE USED WITH EM

DOTTED DEVICES INDICATE ALTERNATE LOCATIONS

BOILER CIRCUIT PIPING MUST BE EQUAL TO

BOILER WATER CONNECTION SIZE

SYSTEM TEMP. INTERLOCK REQUIRED

MULTIPLE STAGE BOILERS RECOMMENDED

2

CAUTION: THIS DRAWING SHOWS SUGGESTED

PIPING CONFIGURATION AND VALVING. CHECK

WITH LOCAL CODES AND ORDINANCES FOR

ADDITIONAL REQUIREMENTS.

BOILER CIRC.

PUMP

SYSTEM PUMP

C

C

C

180° F

180° F

140° F

120° F

NOTES:

1. BOILER LOOP TO BE MAINTAINED AT 180° F.

2. ZONE THERMOSTATS TO BE INTERLOCKED WITH BOILER.

BOILER TO FIRE UPON CALL FOR HEAT FROM ANY ZONE.

3. ZONE PIPING AND INTERLOCK WIRING TO BE

DESIGNED BY SYSTEM DESIGNER.

COLD WATER

MAKE-UP

OPTIONAL PUMP MOUNTED UNIT AVAILABLE

C

D

D

D

DIMENSION ''C'' TO BE 4 PIPE DIAMETERS

DIMENSION ''D'' TO BE 18" MINIMUM

Figure 6. Hydronic Piping — One Boiler, Multi-Temperature System.

Temperature Rise in Degrees (°F/°C)

20°F

11°C

25°F

14°C

30°F

17°C

Model

Flow

H/L

Flow

H/L

Flow

H/L

Flow

H/L

Flow

H/L

Flow

H/L

(Size)

gpm

feet

lpm

m

gpm

feet

lpm

m

gpm

feet

lpm

m

1200

104

18

395

5.5

84

12

316

3.7

70

8

264

2.4

1600

139

22

527

6.7

111

14

422

4.3

93

10

351

3.0

2000

174

20

659

6.1

139

13

527

4.0

116

9

439

2.7

2400

209

18

791

5.5

167

12

632

3.7

139

8

527

2.4

NOTE: Maximum temperature rise is 30°F (17°C), as shown. Headloss is for boiler’s heat exchanger only.

Table 8. Water Flow Requirements, RHCH (Boiler).