Laars heating systems, Page 16 – LAARS Rheos RHCV - Install and Operating Manual User Manual

Page 16

LAARS Heating Systems

Page 16

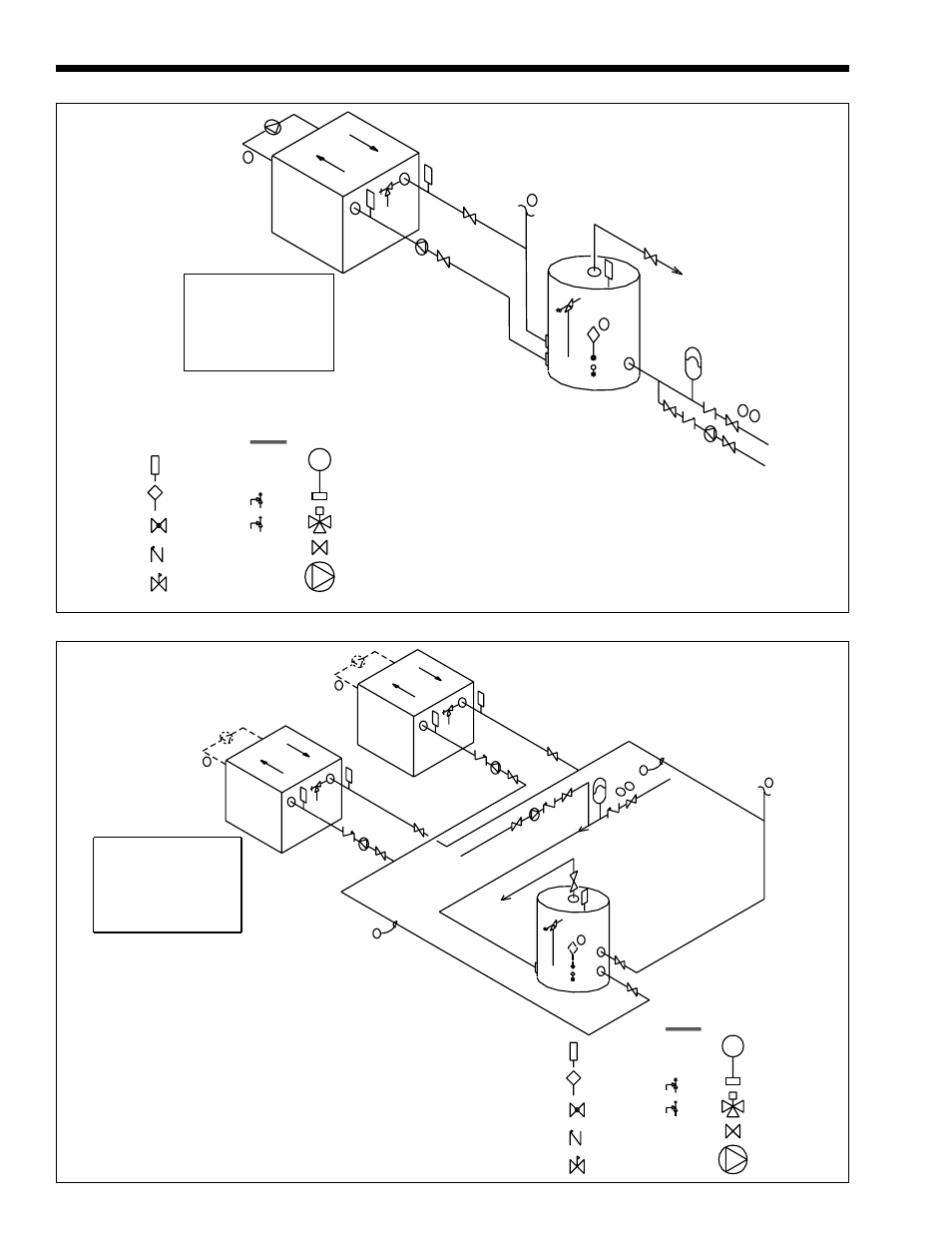

THERMOMETER

GLOBE VALVE

CHECK VALVE

PRESSURE REDUCING VALVE

W/ FAST FILL BYPASS

EXPANSION TANK

WITH AIR SCOOP AND

AUTO AIR VENT

PUMP

LEGEND

VALVE

TEMPERATURE

SENSOR

3-WAY VALVE

NOTES:

7. CAUTION: PUMP SIZING MUST BE BASED UPON WATER HARDNESS AT JOB SITE

CAUTION: THIS DRAWING SHOWS SUGGESTED

PIPING CONFIGURATION AND VALVING CHECK

PRV

WITH LOCAL CODES AND ORDINANCES FOR

ADDITIONAL REQUIREMENTS

WATER CATEGORY GRAIN

HARDNESS PER GALLON

S = SOFT

1 THROUGH 7.5

N = NORMAL 7.6 THROUGH 17

H = HARD

OVER 18

17.1 PARTS PER MILLION

= 1 GRAIN HARDNESS PER GALLON

KEY:

2

SUPPL

Y

RECIRC.

CWMU

1. OPTIONAL CWMU & RECIRC. LINE LOCATION.

2. WHEN USING INTERMITTENT PUMP AND EM LOCATE REMOTE AQUASTAT

WELL IN LOWER 1/3 OF TANK WITH HEAT SENCEING COMPOUND.

3. BACK FLOW PREVENTER MAY BE REQUIRED CHECK LOCAL CODES.

4. THERMAL EXPANSION TANK MAY BE REQUIRED CHECK LOCAL CODES.

5. WHEN USING OPTIONAL FACTORY MOUNTED PUMP, MAX PIPE LENGTH

30' TOTAL, 6-90° ELBOWS , FULL PIPE SIZE.

6. THIS DRAWING DEPICTS A TWO-PASS HEAT EXCHANGER.

5

TPRV

3 4

2

1

THERMOMETER

GLOBE VALVE

CHECK VALVE

PRESSURE REDUCING VALVE

W/ FAST FILL BYPASS

EXPANSION TANK

WITH AIR SCOOP AND

AUTO AIR VENT

PUMP

LEGEND

VALVE

TEMPERATURE

SENSOR

3-WAY VALVE

CAUTION: THIS DRAWING SHOWS SUGGESTED

PIPING CONFIGURATION AND VALVING CHECK

PRV

WITH LOCAL CODES AND ORDINANCES FOR

ADDITIONAL REQUIREMENTS

WATER CATEGORY GRAIN

HARDNESS PER GALLON

S = SOFT

1 THROUGH 7.5

N = NORMAL 7.6 THROUGH 17

H = HARD

OVER 18

KEY:

TPRV

6. THIS DRAWING DEPICTS A TWO-PASS HEAT EXCHANGER.

30' TOTAL, 6-90° ELBOWS , FULL PIPE SIZE.

5. WHEN USING OPTIONAL FACTORY MOUNTED PUMP, MAX PIPE LENGTH

4. THERMAL EXPANSION TANK MAY BE REQUIRED CHECK LOCAL CODES.

3. BACK FLOW PREVENTER MAY BE REQUIRED CHECK LOCAL CODES.

WELL IN LOWER 1/3 OF TANK WITH HEAT SENCEING COMPOUND.

2. WHEN USING INTERMITTENT PUMP AND EM LOCATE REMOTE AQUASTAT

1. OPTIONAL CWMU & RECIRC. LINE LOCATION.

8. CAUTION: PUMP SIZING MUST BE BASED UPON WATER HARDNESS AT JOB SITE

NOTES:

2

5

SU

PPL

Y

CIR

C. R

ETU

RN

2

3

CW

MU

4

1

5

7. COMMON PIPING MUST BE SIZED FOR MAXIMUM COMBINED HEATER FLOW.

7

7

17.1 PARTS PER MILLION

= 1 GRAIN HARDNESS PER GALLON

Figure 9. Water Heater Piping — One Heater, One Tank.

Figure 10. Water Heater Piping — Multiple Heaters, One Tank.