2 using the turbo waste gate control – Haltech F10 User Manual

Page 78

73

16.2.2 Using the Turbo Waste Gate Control

In order to use the Turbo Waste Gate Control function, you will need the following:

A suitable pressure solenoid valve (available from your Haltech Dealer);

Air hose and fittings;

F10A programming software and cable;

An overboost relief valve (strongly recommended).

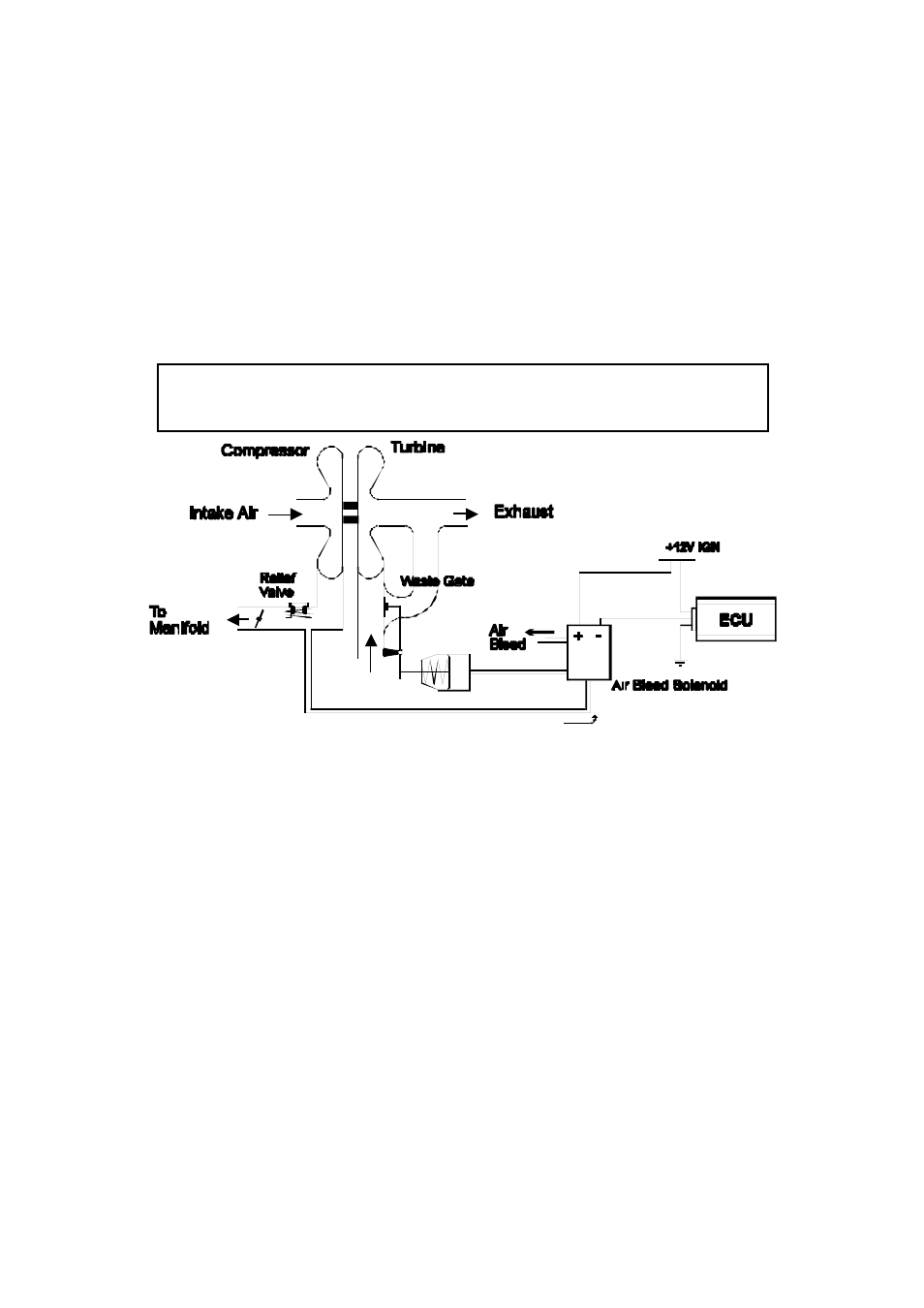

The air circuit to the waste gate must be configured appropriately, as in figure 16.2. Install the

solenoid valve securely, and power and signal from the output connector on the harness. The

wastegate should be re-set so that its operation point is very low, around 20kPa (3 psi).

Note: Be sure to use air hose that is rated to the pressure the engine is expected

to be boosted to. All fittings should be secured so that they will not disconnect

under high pressures.

Figure 16.2. Diagram of Turbo with Wastegate Control Solenoid.

A relief valve should be fitted to the manifold as a backup in case of an air hose failure and

uncontrolled boost.

Once the solenoid installation is complete run the F10A software in ONLINE mode. Select

the Turbo Wastegate Control Function on the appropriate output channel, and set the

following parameters.

Period

This sets the period of oscillation of the solenoid. M ost solenoids will operate at

around 30Hz, which corresponds to a period of about 30ms. Enter the desired

oscillation period in milliseconds here.

Use Map

This sets which map (map 1 or map 2) is used to perform waste gate control. The

reason for having two maps is so one map can be tuned for street driving and the other

for racing. The two turbo waste-gate maps are found in the M aps menu of the F10

software