6 duty cycles – Haltech F10 User Manual

Page 43

38

4.6 Duty Cycles

Fuel is delivered to the engine by firing the injectors in sync with the engine, allowing fuel to

flow during the period that the injector is open. The period of time the injector is open is

called the injector pulsewidth. As rpm increases it is possible for consecutive pulses of the

injectors to meet so that the injectors are effectively never switched off. This is referred to as

100% duty cycle.

When 100% duty cycle is reached the fuel flow from the injectors has reached its maximum.

Increasing engine speed or load will result in a lean out condition.

WARN ING:

LEANING OUT AN ENGIN E WILL C AUSE DAMAGE TO THE

ENGINE IN MOST CASES.

CARE SHOULD BE TAKEN THAT THE ENGIN E CANNOT REV

ABOVE THE POINT WHEN 100% DUTY CYC LE IS REACHED AS

THERE IS A DANGER THAT DAMAGE WILL BE C AUSED TO THE

ENGINE

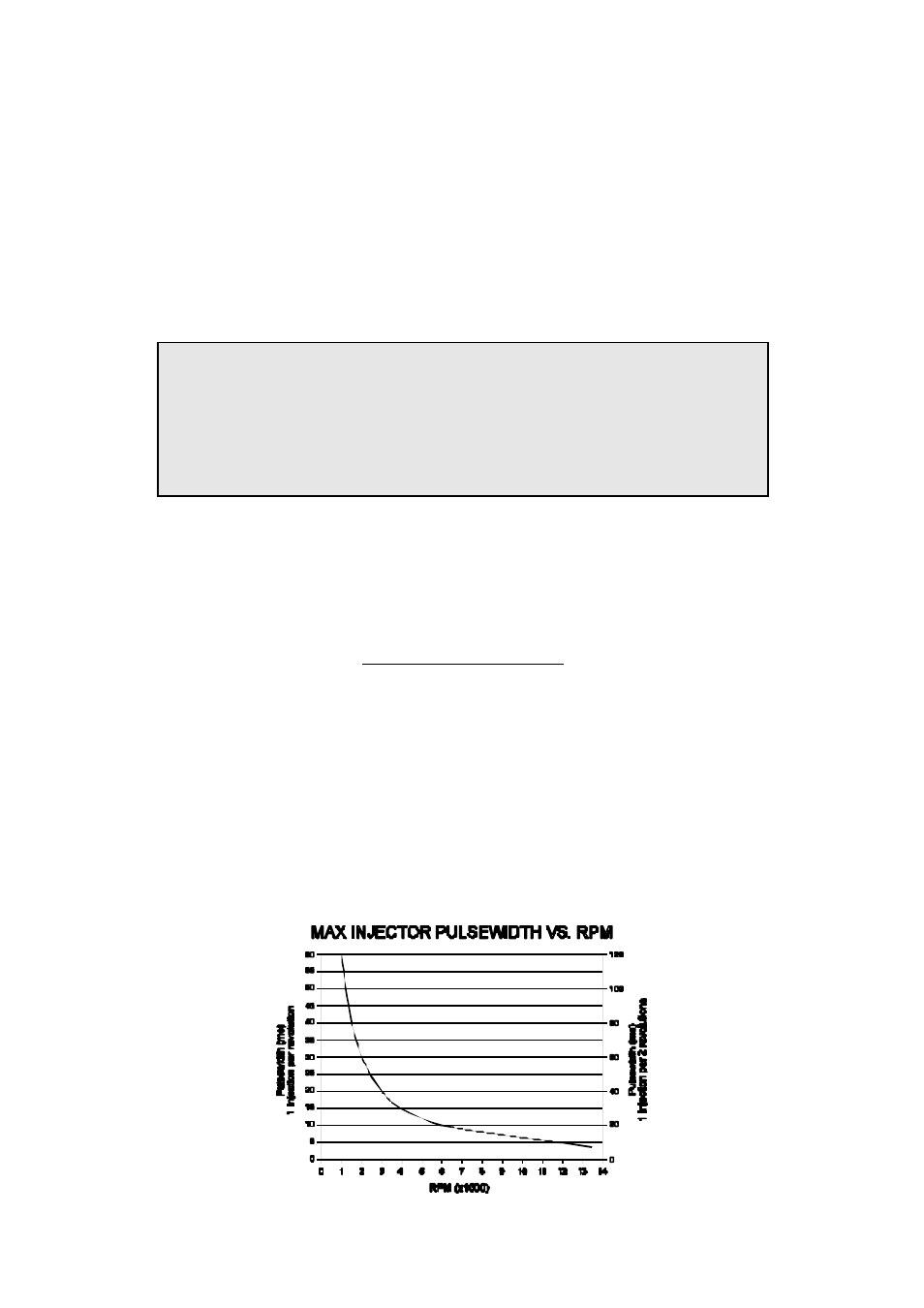

The table and graph below show the point at which the injectors will reach 100% duty cycle.

It is not common for this to happen but the potential for damage under these circumstances is

high, so care should be taken to check this factor.

Maximum Injection Time (in milliseconds[ms]) =

(120,000 x IgnDivideBy)

(Rpm x No. Cylinders)

eg. M aximum injection time for a four cylinder, on ign/by 2 red-lining at 6000rpm is:

(120,000 x 2)/(6000 x 4) = 10,

The maximum injection time at 6000rpm on this engine is 10ms. If the injection time needs to

be greater than this, then your fuel system cannot meet the demands of the engine. You will

need to increase the fuel supply, by increasing injector size, fuel pressure, or adding extra

injectors. (Refer Appendix C Fuel Systems & Staging, 89). As a general rule of thumb,

injectors should not run beyond 85% duty cycle.