Appendix – Great Planes Tracer 46 Kit - GPMA0400 User Manual

Page 43

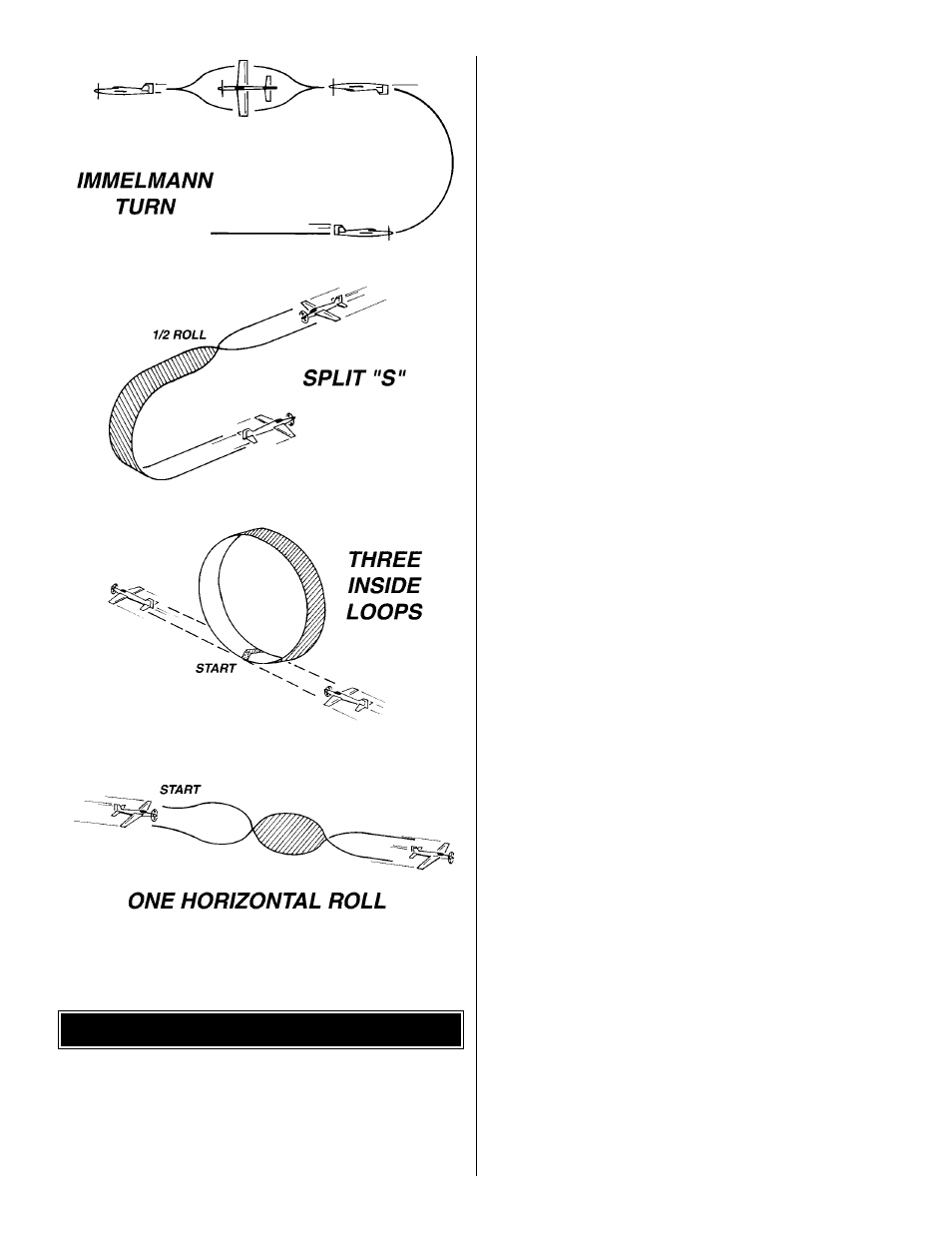

6. Immelmann Turn (U)

7. Split “S”

8. Three (3) Inside Loops (U)

9. One (1) Horizontal Roll (D)

10. Landing (U)

FLIGHT TRIMMING

Note: The following article has been reprinted in part for

future reference and also as a guide for your flight instructor

or experienced flying partner to help you with trimming your

model. If further information is required, please contact your

local hobby dealer, local flying club or call Great Planes at

(217) 398-8970.

A model is not a static object. Unlike a car, which you can

only hunt left or right on the road (technically, a car does

yaw in corners and pitches when the brakes are applied), a

plane moves through that fluid we call air in all directions

simultaneously. The plane may look like it’s going forward,

but it could also be yawing slightly, slipping a little and

simultaneously climbing or diving a bit! The controls

interact. Yaw can be a rudder problem, a lateral balance

problem or an aileron rigging problem. We must make many

flights, with minor changes between each, to isolate and

finally correct the problem.

The chart accompanying this article is intended to serve

as a handy field reference when trimming your model.

Laminate it in plastic and keep it in you flight box. You just

might have need to consult it at the next contest! The chart

is somewhat self-explanatory, but we will briefly run through

the salient points.

First, we are assuming that the model has been C.G.

balanced according to the manufacturer’s directions.

There’s nothing sacred about that spot — frankly, it only

reflects the balance point where a prototype model handled

the way the guy who designed it thought it should. If your

model’s wing has a degree more or less of incidence, then

the whole balance formula is incorrect for you. But, it’s a

good ballpark place to start.

The second assumption is that the model has been

balanced laterally. Wrap a strong string or monofilament

around the prop shaft behind the spinner, then tie the other

end to the tail wheel or to a screw driven into the bottom of

the aft fuse. Make the string into a bridle harness and

suspend the entire model inverted (yes, with the wing on!).

If the right wing always drops, sink some screws or lead

into the left wing tip, etc. You may be surprised to find out

how much lead is needed.

At this point the model is statically trimmed. It’s only a

starting point, so don’t be surprised if you wind up changing

it all. One other critical feature is that the ailerons must

have their hinge gap sealed. If shoving some Scotch tape

or MonoKote into the hinge gap to prevent the air from

slipping from the top of the wing to the bottom and vice-

versa, bothers you, then don’t do it.

To achieve the maximum lateral trim on the model, the

hinge gap on the ailerons should be sealed. The easiest

way to do this is to disconnect the aileron linkages and fold

the ailerons as far over the top of the wing as possible

(assuming they are top or center hinged). Apply a strip of

clear tape along the joint line. When the aileron is returned

to neutral, the tape will be invisible and the gap will be

effectively sealed. Depending on how big the ailerons are

and how large a gaping gap you normally leave when you

install hinges, you could experience a 20 percent increase

in aileron control response just by this simple measure.

Your first flights should be to ascertain control centering

and control feel. Does the elevator always come back to

neutral after a 180° turn or Split-S? Do the ailerons tend to

hunt a little after a rolling maneuver? Put the plane through

APPENDIX

43