Assemble the cowl – Great Planes Spitfire 40 Kit - GPMA0179 User Manual

Page 29

❏

2. Drill a 1/8" (or 7/64") hole 5/8" deep in the leading edge

of the rudder at the mark you made for the tailgear wire. Cut a

groove in the rudder for the nylon tailgear bearing (use a Great

Planes Groove Tube tool or a 5/32" brass tube sharpened at

one end to cut the groove). Test fit the tailgear wire in the rudder.

❏

3. Position the control horn on the rudder as shown in the

sketch and on the plan. Use a ballpoint pen to mark the location

of the control horn mounting holes and drill 3/32" holes at the

marks. Temporarily mount the control horn to the rudder with

the backing plate and two 2-56 x 5/8" screws, trapping the

tailgear wire between the screws. Remove the control horn.

❏

4. Cut a slot in the trailing edge of the fuse at the marks you

made for the nylon tailgear bearing. Without using any glue, test

fit the rudder to the fin with the tailgear wire until there is no gap.

❏

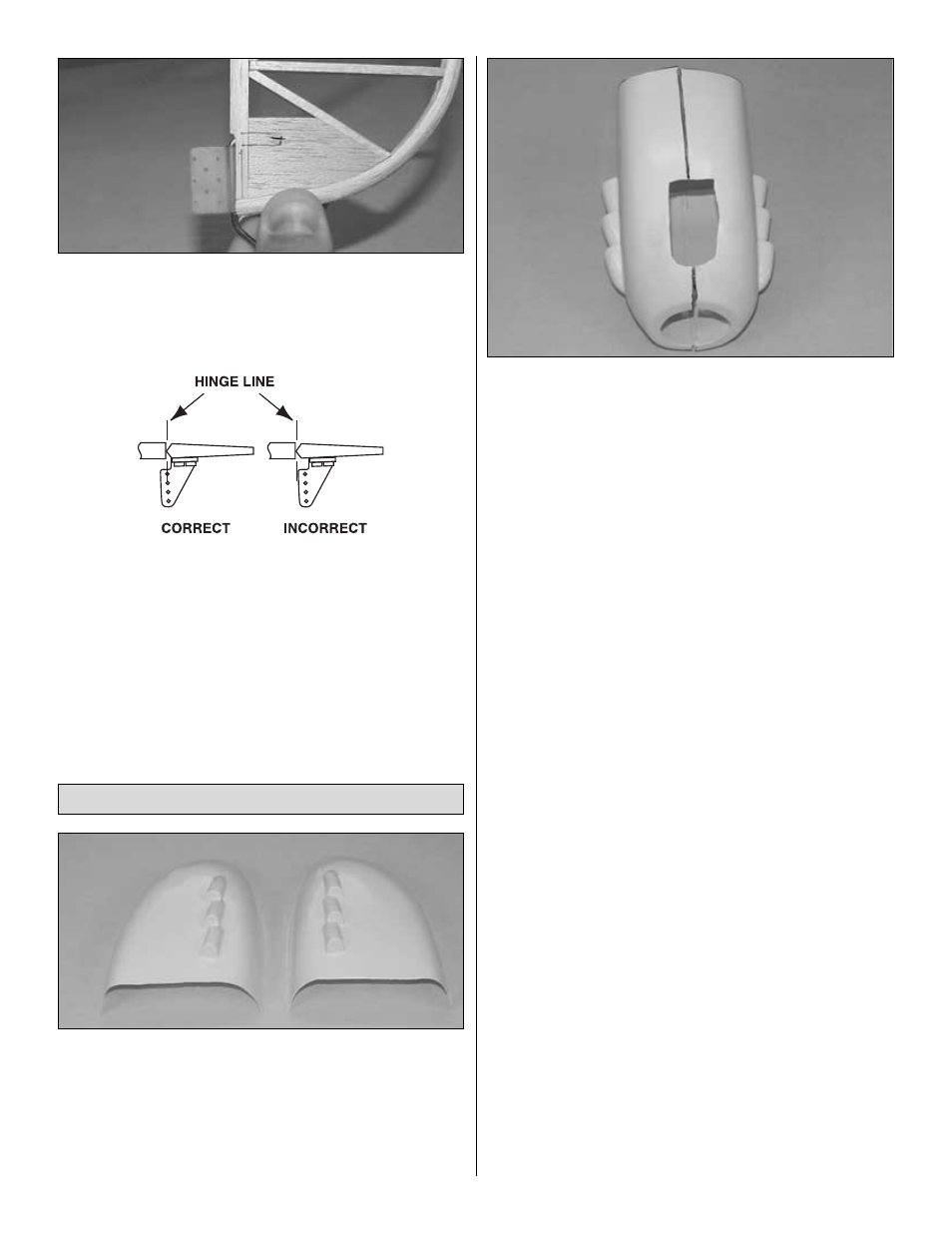

1. Cut the cowl halves along the cutlines, then use a bar

sander with 80-grit sandpaper to true all the edges. To check

the straightness of the edges, set the cowl half on its seams on

the building board to be sure it is straight and smooth.

❏

2. For now, just rough cut the openings in the front of each

cowl half. Using coarse sandpaper, roughen 1/2" along the

overlaps of each cowl half so the glue will stick.

❏

3. Tape the two pieces together, using several pieces of masking

tape and taping across the seams. Note the overlap in the cowl halves.

❏

4. Test fit the cowl to the fuselage and adjust the taped seams

as needed for a proper fit. Carefully remove the cowl from the

fuselage.

Note: You may need to remove your engine’s needle

valve, exhaust and possibly even the head to test fit the cowl.

❏

5. Cut four 1" sections off the 1" x 18" fiberglass tape and

set aside for the cowl mounting screw locations. Secure the

inside of the cowl seams with the remaining fiberglass tape and

thin CA.

❏

6. Use a sharp hobby knife or a Dremel Multi-Tool with a sanding

drum to accurately cut the openings at the front of the cowl.

❏

7. Slide the cowl onto the fuselage. Slide the spinner backplate

over the crankshaft, moving the cowl as necessary to leave a

1/8" gap between spinner and cowl, and secure the backplate

in place. Position the cowl so that it aligns properly with the

spinner.

❏

8. Hold the cowl in position tight against the front deck

sheeting and aligned with the spinner. Drill the first cowl

mounting screw hole with a 1/16" drill bit. Screw in place with a

#2 x 3/8" screw.

❏

9. Confirming the proper positioning of the cowl before drilling

each hole, drill the remaining holes and install the remaining 3

screws one at a time.

❏

10. Remove the screws and the cowl from the model. Enlarge

the pilot holes you just made in the fuse with a 1/8" drill bit.

From the 6" piece of white pushrod inner, cut four 1/4" lengths,

making four

cowl screw retainers. Push the retainers into

each hole until flush with the fuselage side. Glue in place with

thin CA from the inside of the fuselage.

Note: These plastic

retainers help keep cowl screws from vibrating loose.

❏

11. Use a piece of thin cardboard or plastic to make a template

for the cutout in the cowl for the valve cover and mixture screw

of the engine, and for access for the glow plug heater. Tape the

template to the fuselage side, accurately indicating the

positions.

❏

12. Remount the cowl in position with the mounting screws,

being careful not to move or damage the paper template. Use

a felt-tip pen to transfer the holes in the template onto the cowl.

Assemble the Cowl

29