Mount the wing to the fuselage – Great Planes Spitfire 40 Kit - GPMA0179 User Manual

Page 21

❏

2. Glue the die-cut 1/8" ply

former F2A to the front of die-cut

1/8" ply

former F2, aligning the dowel holes. Note: The embossed

labels on each former are on the front side.

❏

3. Position the die-cut 3/32" balsa

formers F5, and F4, then

the die-cut 1/8" ply

formers F3 and F2 into their notches in the

fuse top. Position the fuse sides inverted over the plan bottom

view, locking into the formers and the fuse top.

❏

4. Position the 1/8" die-cut ply

aft fuse bottom AFB between

the fuse sides and onto the formers. Checking that the fuse

sides are perpendicular to the work surface as you go, glue all

joints, working from the aft end of the fuse forward.

❏

5. Lift the fuselage off the plans. Carefully inspect all glue joints,

and reinforce any weak joints with medium CA on the inside of

the fuselage.

❏

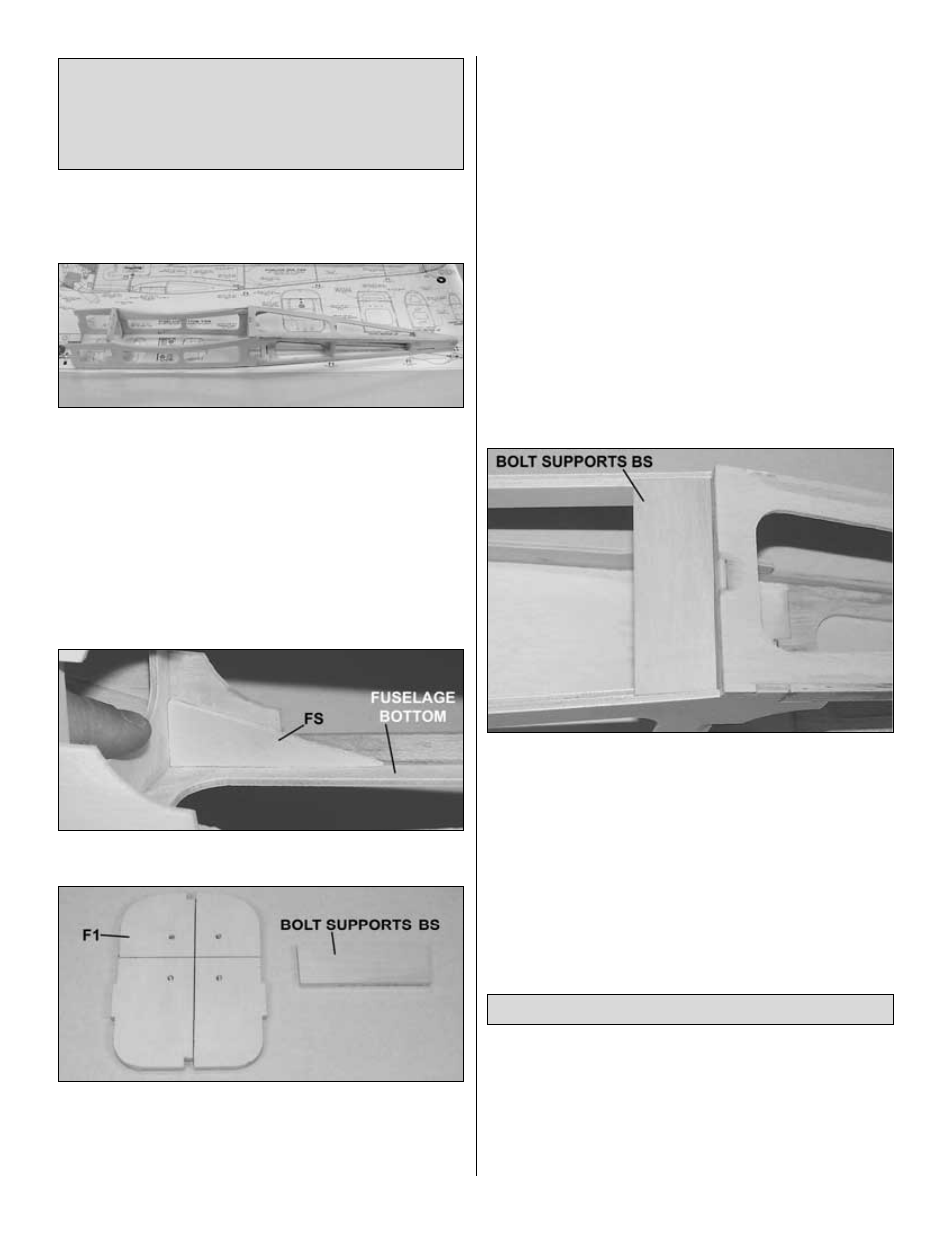

6. Glue the two die-cut 1/8" ply

fuse supports FS in place

in the bottom corners of the fuse.

❏

7.

Note: Refer to this photo for the following four steps.

Glue the two die-cut 1/8"

ply bolt supports BS together.

❏

8. Place one die-cut 1/8" ply

former F1 on the building board,

punch marks and embossing facing up. Epoxy the second F-1

to the first with 30-minute epoxy, again with the punch marks

facing up. Make sure the edges all the way around are aligned.

Wipe away excess epoxy before it cures. From now on this

assembly will be referred to as the

firewall. Note: If the formers

are warped, simply clamping them together may not “cancel

out” the warps. It is best to clamp the formers to a table or a flat

board until the epoxy cures.

❏

9. Using a straightedge, draw lines horizontally and vertically,

connecting the punch marks. The intersection of these two lines

is the center of the engine mount.

Note: This location is offset for the right thrust built into the model

so that the spinner will still align with the center of the cowl.

❏

10. Drill the four 11/64" (5/32" is OK) holes at the punch marks

as shown in the photo for the included Great Planes Engine

Mount. Press the four supplied 6-32 blind nuts into the holes on

the back of the firewall. Gently tap the blind nuts with a hammer

to fully seat them into the firewall, then add a few drops of thin

CA around the blind nuts to secure them. Take care not to get

any CA into the threads of the blind nut.

❏

11. Using 6-minute epoxy, position and glue BS into the wing

saddle, notched tight into both fuse doublers and against both

fuse sides.

❏

1. If necessary, sand the entire wing saddle area lightly until

the fuse side doublers and fuse sides are flush.

Note: Be

careful not to sand an angle into the wing saddle.

❏

2. Test fit the wing on the fuse. Center the wing side-to-side,

leaving equal space between the fuse sides and the wing at the

leading edge. If necessary, sand or trim the wing’s trailing edge

slightly to properly fit the wing saddle.

Mount the Wing to the Fuselage

DESIGNER’S NOTE: The 2° right thrust built into the firewall

helps keep the aircraft tracking straight under acceleration and

deceleration, minimizing the need to apply right rudder in

coordination with throttle. This design requires no down thrust.

The thrust angles built into this aircraft have been extensively

tested and we recommend you do not modify them.

21