Assembly of the model – Great Planes Cherokee Kit - GPMA0180 User Manual

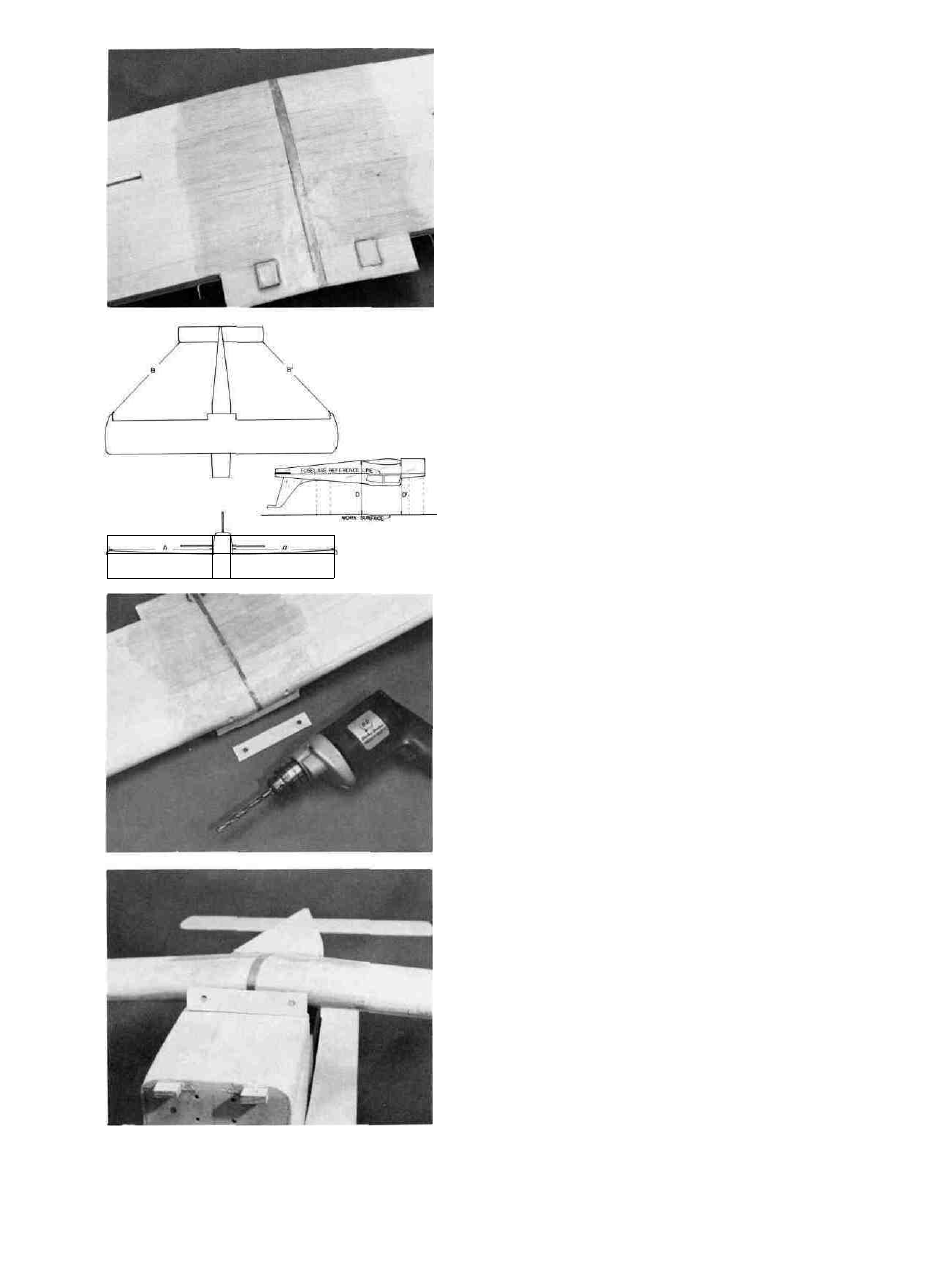

Page 23

WORK SURFACE

2. D GLASS THE WING ; ADD THE 1/16" PLY PLATES

Apply a thin coat of polyester resin (or thinned epoxy)

to the wing center section. Lay the cloth on the wing. Add

more resin (or epoxy). Immediately squeegee off the ex-

cess. Let cure until dry. Sand the glass lightly. Brush on a

second coat of resin and let it dry (or apply a second coat

of epoxy). Let that coat dry. Turn the wing over and glass

the other side of the wing, overlapping the cloth at the

wing leading edge and trailing edge. Finish sand the wing

when the glass is dry. Now glue on the 1/16" x 3/4" x 1" Ply-

wood Wing Plate on the bottom of each Center Trailing

Edge piece.

ASSEMBLY OF THE MODEL

1. D ALIGN THE FUSELAGE TO THE WORK SURFACE

AND THE WING TO THE FUSELAGE

Align the Fuselage to the work surface using the line

along the top of the Fuselage Side as the reference point.

This line should be parallel to the flat work surface with

the Fuselage upside down. Align the Wing to the Fuselage

by making the following measurements: A-Center the Wing

side to side in the saddle. The distance from the Fuselage

Side to the Wing Tip on each side should be the same.

B-The Wing Tip to Stab Tip distance should be the same.

C-Wing Wing to work surface distance should be the same

on both sides. D-The Wing has 0 degrees incidence like the

Stabilizer. The Leading Edge to work surface should be the

same as the trailing edge to work surface distance. When

the wing is aligned correctly, mark the position of the wing

on the Fuselage so you can realign the wing again. (Re-

member these measurements will not work unless you

have aligned the Fuselage to the work surface first. The

reference line should be parallel to the work surface.

Measure from this line down to the work surface at several

points on both sides of the Fuselage. All the measure-

ments should be the same.)

2. D USE DOWEL JIG AND DRILL HOLES IN THE

WING LEADING EDGE FOR DOWELS

(The Dowel Jig is used to help you drill holes in the

Wing leading edge. The Jig also gives you the location of

the 1/4" holes in Bulkhead #2. You drill the Wing holes first,

position the Dowels and Jig and then drill the holes in the

Bulkhead after the Wing is in position.) Use the plan and

mark and drill 1/4" holes in the 1/8" Ply Dowel Jig piece

(1/8" x 7/8" x 4-9/16"). Center the Dowel Jig over the Wing

Leading Edge making sure the holes in the Jig are cen-

tered on the Wing Leading Edge centerline. Drill 1/4" holes

into the wing leading edge and through both 1/16" Dowel

Plates inside the wing. Be sure that the holes are drilled

parallel to the rib centerlines and at 90 degrees to the wing

leading edge.

3. D REALIGN THE WING TO THE FUSELAGE;

GLUE DOWEL JIG TO FUSELAGE

Place 1/4" Dowels into the holes in the Wing leading

edge. Place the Dowel Jig on the Dowels. Position the

Dowels so they are flush with the Dowel Jig when the Jig is

next to the Wing. You may want to tack glue the Dowels to

the Wing so they don't fall inside the Wing during this step.

Now place the Wing, Dowels and Dowl Jig into the Wing

Saddle. Realign the Wing. Push the Dowel Jig forward

against Bulkhead #2 and tack glue the Dowel Jig to the

rear of Bulkhead #2. Remove the Wing and Dowels from

the Fuselage.

23