Hook up the ailerons – Great Planes 38% Extra 330S ARF - GPMA1290 User Manual

Page 7

7

❏

5. Connect a 12" [305mm] servo extension (HCAM2711

for Futaba) to one of the aileron servos and 36" [915mm]

servo extension (HCAM2726 for Futaba) to the other aileron

servo. Secure each connection with 1-1/2" [38mm] pieces

of heat shrink tubing cut from one of the 3" [75mm] pieces

included with this kit.

❏

6. Tie the string in one of the wings to the servo wires as

shown. Then, pull them through the tube in the wing.

❏

7. Place the aileron servos in the servo openings of one

of the wings. Drill 1/16" [1.6mm] holes for the servo mounting

screws. Temporarily mount the servos with the screws that

came with them. Note: For some JR (or other brand) servos,

the servo mounts may require slight trimming to accommodate

the servos and larger holes may have to be drilled for larger

servo mounting screws.

❏

8. IMPORTANT: Remove the servo mounting screws

and set the servos aside (without pulling the servo leads

out of the wing). Add a few drops of thin CA to each screw

hole to harden the “threads.” Allow the CA to harden. Then,

remount the servos.

Whenever screws are mounted into wood you must harden

the holes with CA after installing, and then removing the

screws. The complete process will not be written out

every time this is necessary. Instead, you will simply be

reminded to “harden the screw holes with thin CA.”

❏

9. Mount the aileron servos in the other wing the same

way—don’t forget to harden the screw holes with thin CA!

Hook Up the Ailerons

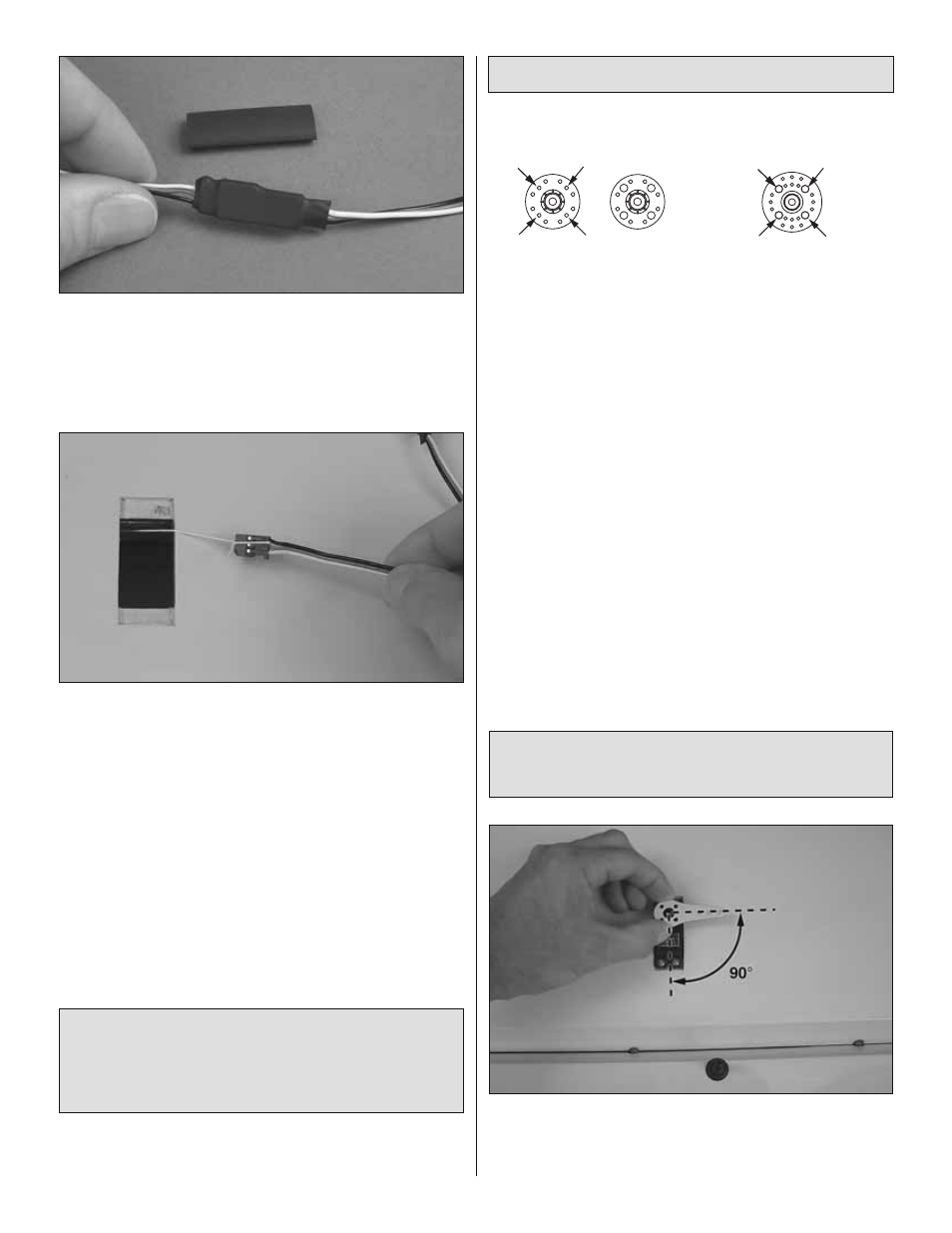

Futaba Servo Wheel

Bottom of Hobbico

Servo Wheel

Enlarge the

holes indicated

Drill holes in

the mold marks.

Use 7/64" [2.8mm]

(or 1/8" [3.2mm]) drill

❏

1. If using Futaba servos, drill out the holes in the servo

wheel with a 7/64" [2.8mm] (or 1/8" [3.2mm]) drill. If using

different servos, use one of the aluminum servo arms that

came with this kit as a template for drilling the holes. All the

servo wheels used for the control surfaces in this model

require drilling, so if you have all your servo wheels handy

you could drill them all now, or just drill them as needed.

Note: The servo wheels that come with the CS/TS35-59, 63-

71 Hobbico Servo Horn set (HCAM1071) have mold marks

in the bottom that happen to align with the holes in the

aluminum servo arms. Double-check to make sure the mold

marks align with the holes in one of the servo arms. Then,

drill 1/16" [1.6mm] pilot holes at the marks. Enlarge the pilot

holes with a 7/64" [2.8mm] (or 1/8" [3.2mm]) drill.

Your radio system will be required for the next step,

so gather your transmitter, receiver, battery and

on/off switch.

❏

2. Connect one of the aileron servos to your receiver and

turn the system on. Center the trim and position the servo

wheel on the servo so that when the top servo arm will be

mounted to the wheel it will be perpendicular to the servo.