Hook up the rudder – Great Planes 38% Extra 330S ARF - GPMA1290 User Manual

Page 13

13

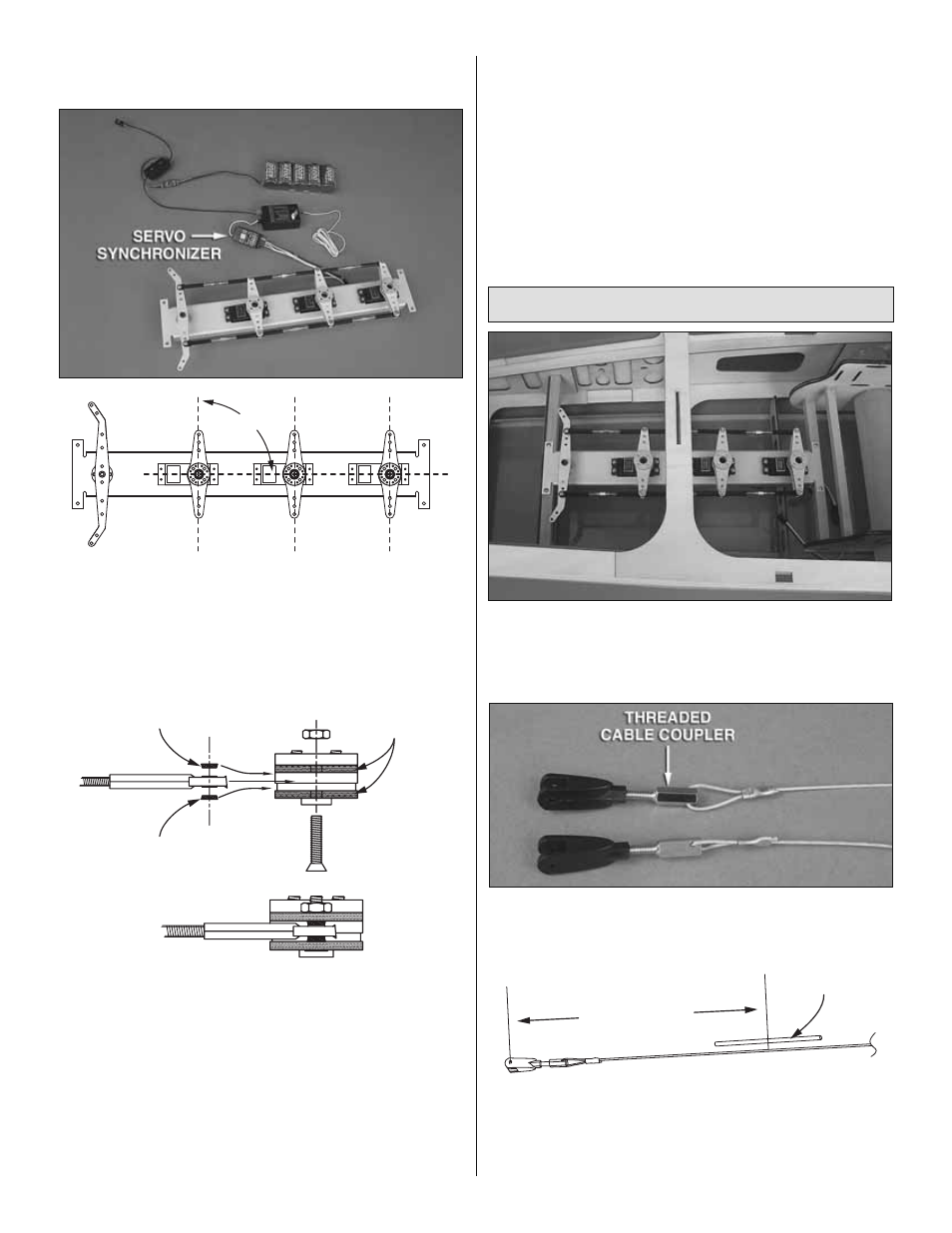

Refer to the following photo to fi nish

mounting the rudder servos.

90°

❏

5. Same as was done for the aileron and elevator servo

wheels, drill the holes in the three rudder servo wheels

with a 7/64" [2.8mm] (or 1/8" [3.2mm]) drill and mount the

double-sided servo arms to the servo wheels. Place the arm

assemblies on the servos and use a servo synchronizer to

center all the servo arms.

1mm Standoff

Double-Sided

Servo Arms

1mm Standoff

❏

6. Connect only the front of both rudder pushrods to the

front rudder servo arm using the same hardware that was

used to connect the aileron and elevator pushrods (that is

two 1mm brass standoffs, a 4-40 x 7/16" [11mm] fl at-head

Phillips screw and a 4-40 nut with threadlocker).

❏

7. Connect the pushrods to the middle rudder servo arm

using the servo synchronizer to align the holes in the arm with

the ball link balls in the pushrod. Using the servo synchronizer,

also make sure the servo arms are synchronized at the ends

of their throw.

❏

8. Connect the rudder pushrods to the aft rudder servo

using the synchronizer again. Don’t forget to use threadlocker

on the threads of all the screws.

❏

9. Finally, connect the last ball links on the end of the

rudder pushrods to the tiller arm with two 4-40 x 1/2" [12mm]

Phillips screws and 4-40 lock nuts.

❏

10. Secure the servo arm assemblies to the servos with the

servo wheel screws that came with the servos—if the screws

go into metal output shafts be certain to use threadlocker on

the threads.

Hook Up the Rudder

❏

1. Center the rudder servo tray assembly on the mounting

rails in the fuselage. Drill 3/32" [2.4mm] holes in the rails for the

mounting screws. Mount the tray with four #4 x 1/2" [13mm]

screws. Don’t forget to harden the screw holes with thin CA.

❏

2. Cut the braided rudder cable into two equal-lengths.

Make the aft end of both rudder cables from the hardware

shown (the “normal-thread” pin clevises are used here).

Shrink Tubing

22" [560mm]

❏

3. Cut the included 1/8" [3.2mm] diameter heat shrink

tubing into two equal lengths. Slide one tube over each cable

until the middle of each one is 22" [560mm] from the end of

the pin clevis. Shrink the tubing over the cables and glue it

into position with thin CA.